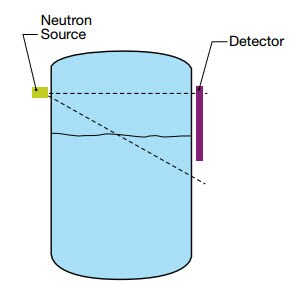

Editor’s Note: The first post in this series discusses a hybrid approach to controlling the contents within a coke drum employing neutron backscatter and gamma transmission. The second post describes the neutron backscatter measurement principle. A hybrid approach to controlling the contents within a coke drum employs neutron backscatter and gamma transmission techniques, as described in the first post in this series. The following installment describes the neutron backscatter measurement principle, and here in this final post we’ll present the gamma transmission measurement principle. Gamma Transmission Measurement Principle A gamma ray source, typically Cesiums-137 (Cs-137), is located on one side of the vessel and a gamma radiation detector is mounted on the other side (see figure below).  The gamma rays are attenuated by any material between the source and the detector (walls, foam, liquid). The signal from the detectors is proportional to the amount of radiation that reaches them. How Much Radiation Reaches the Detector? The attenuation of gamma rays is proportional to the density of the material and the length of the path through that material. The formula is roughly att= exp(-0.0357 × density(lb/cft) × path length (ft)). If we have a coker with an internal diameter of 25 ft, we can calculate the attenuation for different materials:

The gamma rays are attenuated by any material between the source and the detector (walls, foam, liquid). The signal from the detectors is proportional to the amount of radiation that reaches them. How Much Radiation Reaches the Detector? The attenuation of gamma rays is proportional to the density of the material and the length of the path through that material. The formula is roughly att= exp(-0.0357 × density(lb/cft) × path length (ft)). If we have a coker with an internal diameter of 25 ft, we can calculate the attenuation for different materials:

- For air at 1 atm (density = 0.0813 lb/cft) we get att = exp(-0.0357 × 0.0813 × 25) = 0.93 This means that only 7% of the radiation would be absorbed by air and 93% of the emitted radiation would reach the detector.

- For water we get: att = 0.000,which means all radiation has been absorbed.

- For foam with a density of 6.25 lb/cft att = 0.004. This means that only 0.4% of the radiation reaches the detector which is equivalent to say that all the radiation has been attenuated by the foam.

- For the vapors (hydrocarbons), density will vary with the pressure. We will suppose a change from 0 lb/cft to 0.1 lb/cft. The corresponding attenuation is att = 1 to 0.914, i.e.: the vapor density change can affect the measurement by a maximum of 8.6%.

This calculation can be redone for different vessel sizes and with Cobalt 60 (Co-60) sources as well. The Co-60 sources are more energetic, therefore it has less attenuation than with Cs-137, but the half life for Co-60 is only 5.4 years versus 30 years for Cs-137. Tables 1 and 2 show the attenuation results for each source. Results The results above show that the gamma transmission technique is affected by changes in vapor densities. It can affect the level measurement by 6.9% on a 20 foot diameter vessel using Cs-137. In addition, the attenuation of the radiation by the foam is very important; almost as much as for the liquid hydrocarbons or coke. This means that the level device will not be able to distinguish between the coke and the foam. It would also be impossible to determine if a change is due to a foam density change or a liquid/coke level change. In summary, the gamma transmission continuous level technique will detect and indicate the edge of the foam level with an error associated to the density changes of the vapor of about 6.9% of span (sensitive length of the detector) per 0.1 lb/cft. Read the application note, Hybrid Solution for the Analysis for Coke Drum Applications. Learn about density and level instruments that offer the best monitoring scheme for both exact control and an overview of what is happening in the delayed coking process.

Leave a Reply