Search

Semiconductor Analysis

FIB Circuit Edit

FIB circuit edit and semiconductor prototyping.

Join the Conversation

FIB circuit edit and rapid prototyping

Time to market is a critical factor in the success of semiconductor devices. Manufacturing timelines are long and difficult to manage, so it is important that early production runs provide functional devices. Late discovery of design issues limiting device performance at final test can lead to months of delays in product introduction timelines while new mask sets are created, and new devices are manufactured.

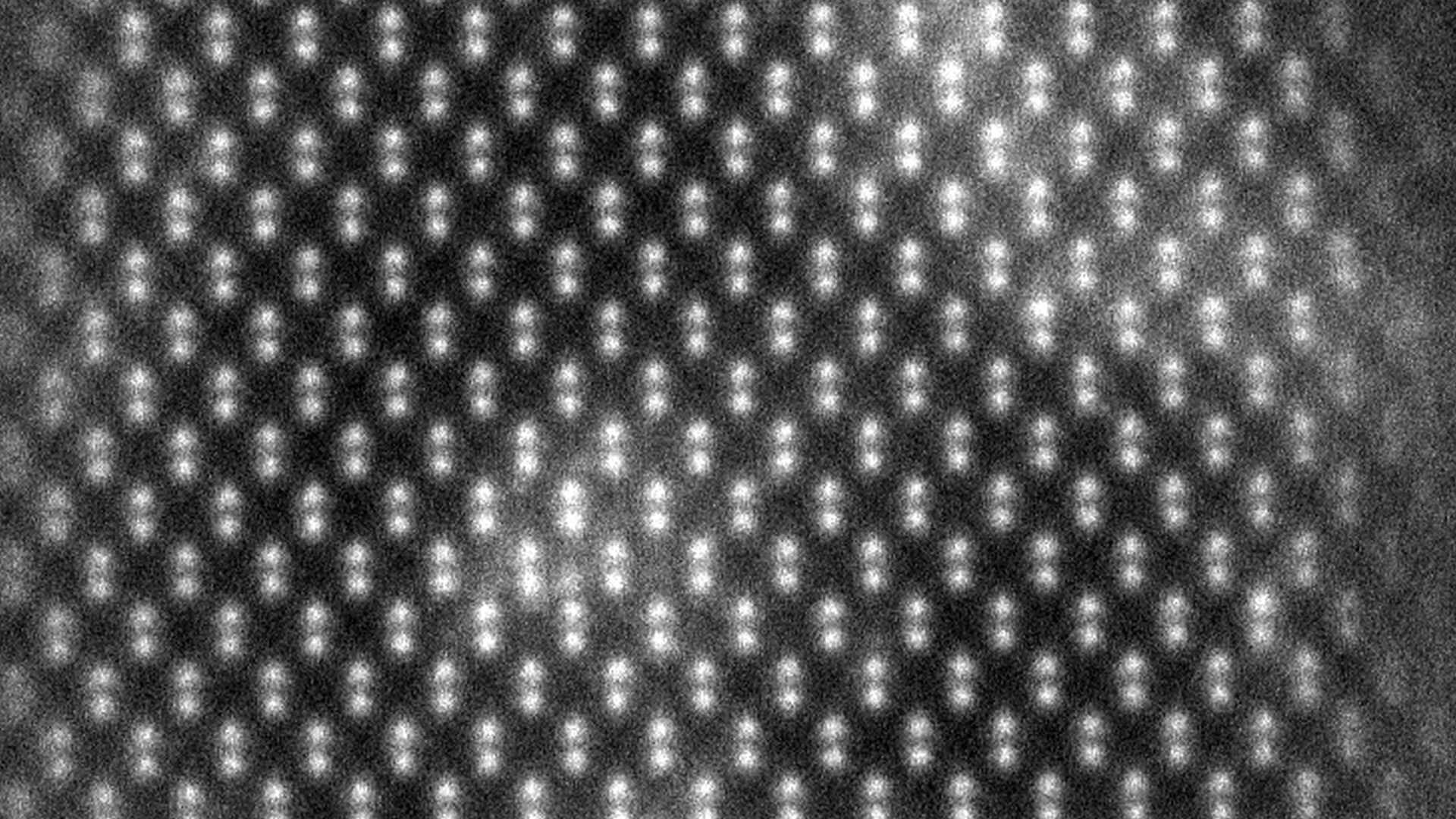

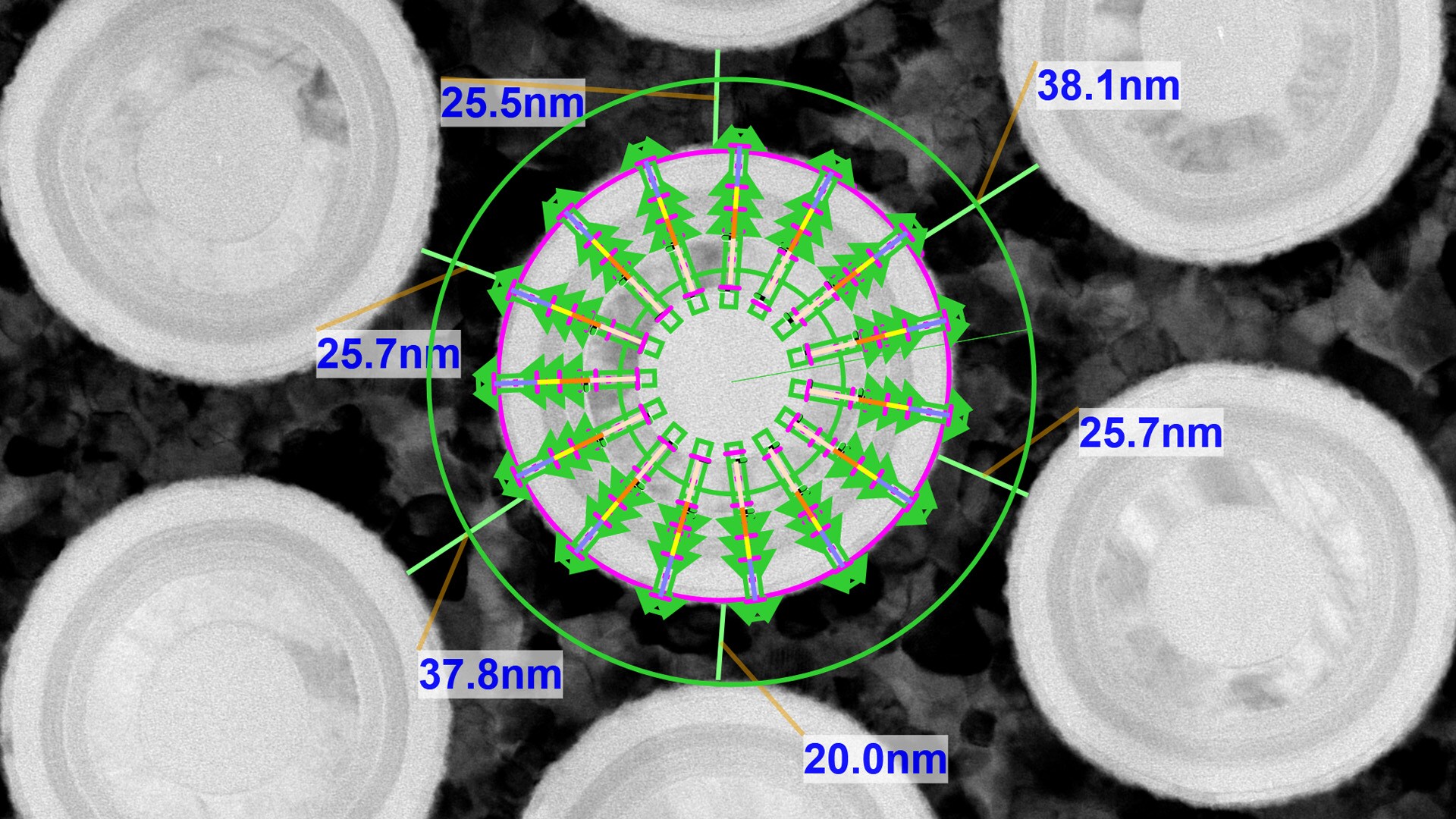

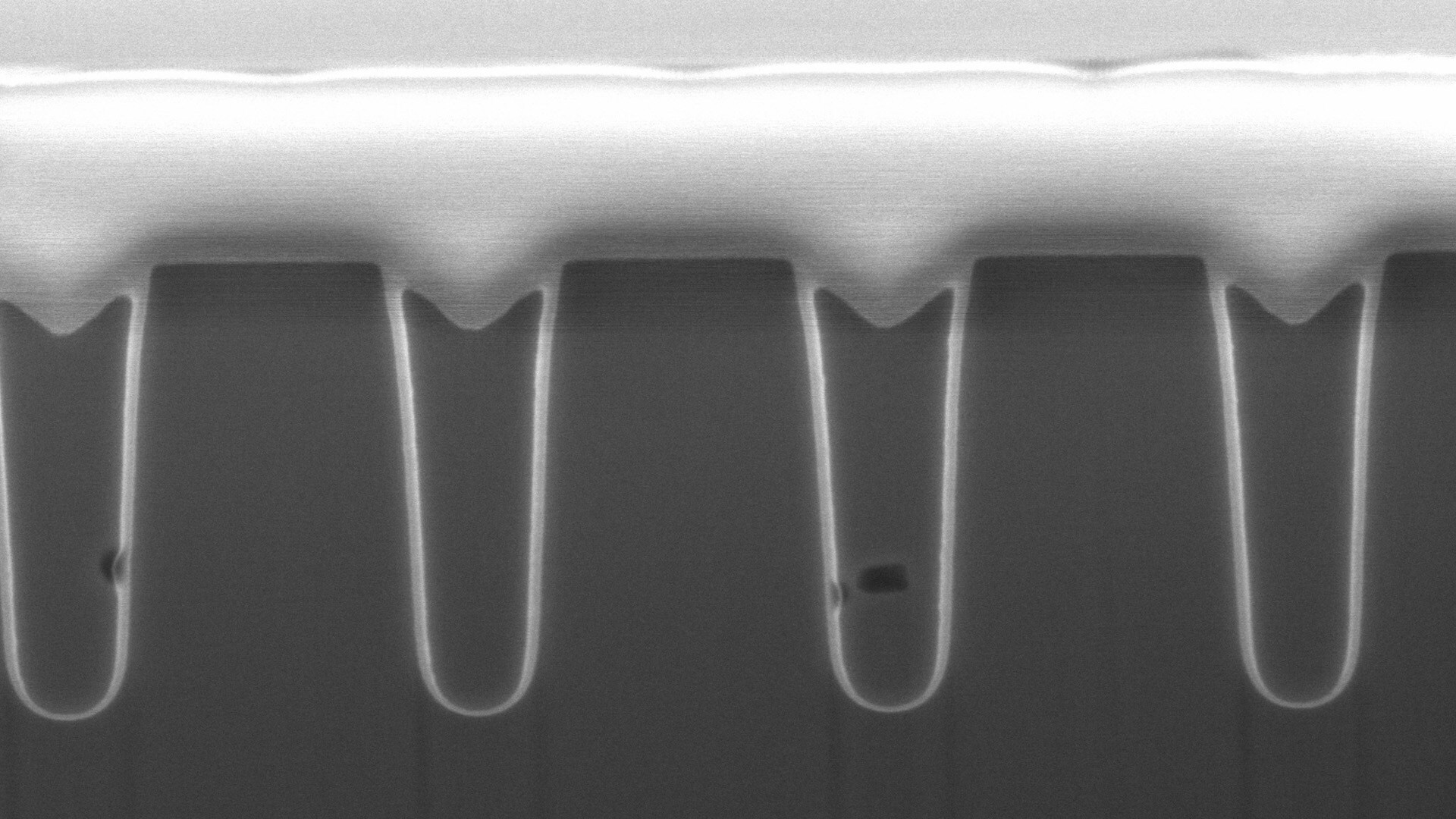

Circuit edit systems provide a solution to test and validate design changes, optimize performance, prototype, and scale functional devices for internal and external customer’s development, validation, and qualification. Circuit edit systems utilize high-resolution focused ion beams (FIBs) and advaced chemistries to perform “nano-surgery” on semi-conductor devices, cutting and creating connections within the device to correct design issues and return functioning products. These working devices keep projects on track without the costs and delays of new mask sets.

Circuit edit systems

With the Thermo Scientific Centrios and Centrios HX Circuit Edit Systems, you can manage program costs, avoid schedule delays, and accelerate time-to-market. The Centrios HX System is designed to meet the circuit editing needs of today’s most advanced semiconductor devices. The Centrios System provides circuit edit capability suitable for a wide range of applications where the required circuit edit performance can be delivered with an improved cost of ownership. Both systems are optimized for the modern, competitive technology world.

Enable working device prototypes and speed up product development cycles with the Centrios HX Circut Edit System.

Fundamentals of Circuit Edit eBook

While circuit editing is a well-established technique, it can be especially difficult for those who are new to it. To help you get started, we asked our circuit edit customers what they wish they had known when they started doing FIB circuit edit and collected their feedback, as well as input from our team of experts, in our new eBook: Fundamentals of Circuit Edit. The eBook includes:

- A definition of circuit edit

- An overview of focused ion beams

- Circuit edit tips from experienced practitioners

- Descriptions of key circuit edit tools and solutions

Fundamentals of Circuit Edit eBook

While circuit editing is a well-established technique, it can be especially difficult for those who are new to it. To help you get started, we asked our circuit edit customers what they wish they had known when they started doing FIB circuit edit and collected their feedback, as well as input from our team of experts, in our new eBook: Fundamentals of Circuit Edit. The eBook includes:

- A definition of circuit edit

- An overview of focused ion beams

- Circuit edit tips from experienced practitioners

- Descriptions of key circuit edit tools and solutions

Semiconductor research and development

Innovation starts with research and development. Learn more about solutions to help you understand innovative structures and materials at the atomic level.

Semiconductor metrology

Manufacturing today’s complex semiconductors requires exact process controls. Learn more about advanced metrology and analysis solutions to accelerate yield learnings.

Semiconductor power devices

Novel architectures and materials pose new challenges. Learn how to pinpoint faults and characterize materials, structures, and interfaces.

Semiconductor Materials and Device Characterization

As semiconductor devices shrink and become more complex, new designs and structures are needed. High-productivity 3D analysis workflows can shorten device development time, maximize yield, and ensure that devices meet the future needs of the industry.