What is Raman spectroscopy?

In Raman spectroscopy, an unknown sample of material is illuminated with monochromatic (single wavelength or single frequency) laser light, which can be absorbed, transmitted, reflected, or scattered by the sample. Light scattered from the sample is due to either elastic collisions of the light with the sample's molecules (Rayleigh scatter) or inelastic collisions (Raman scatter). Whereas Rayleigh scattered light has the same frequency (wavelength) of the incident laser light, Raman scattered light returns from the sample at different frequencies corresponding to the vibrational frequencies of the bonds of the molecules in the sample.

If you wish to learn more about Raman spectroscopy, visit our online Raman Spectroscopy Academy (https://www.thermofisher.com/us/en/home/industrial/spectroscopy-elemental-isotope-analysis/spectroscopy-elemental-isotope-analysis-learning-center/molecular-spectroscopy-information/raman-technology.html), where you will find basic Raman tutorials, advanced Raman webinars on sample applications, and a helpful instrument guide.

Using the Beer-Lambert law in FTIR ATR for quantitative analysis of a time-sensitive, migrating substance (e.g., erucamide) in a polymer is difficult. How can this be overcome?

The Beer-Lambert law is based on stable samples and reproducible conditions. In ATR, you have two concerns. First, the sample must make contact with the crystal in a consistent manner. If the material is rough or crystalline, you must ensure reproducibility. Grinding the material to a fine powder may be necessary. Second, ATR is a surface technique, examining the sample to a depth of around 1-4 microns. If the additive or target molecule is migrating further away, you will lose the signal. In this case, transmission, which illuminates the entire sample and entire thickness, may be a viable option (depending upon thickness). In some cases, the application of pressure can change the signal due to changes in the crystallinity or orientation of polymer strands in the sample. Any deeper insights would require an understanding of the specific sample involved.

What types of sampling cells and detectors are used for protein analysis using Fourier Transform Infrared Spectroscopy (FTIR)?

One key experimental step in protein analysis is the removal of the water bands (most proteins are in buffers). This requires highly controlled path-length transmission cells or ATR. Most historical work was done in 6-10 micron path length transmission cells using BaF2 or similar windows. The analytical region is roughly between 1400 and 1750cm-1 where these windows are transmissive. Recently, ATR devices using silicon, germanium, or diamond windows have become more prevalent. Reactions or binding of proteins to the crystal can occur with ZnSe devices (due to surface charges); sometimes this is desired but often it is not. Most of the literature is based on transmission cells. Protein analysis requires skill and consistency, so training is essential for most laboratories.

What is the advantage of DRIFTS compared to ATR technique in Fourier Transform Infrared Spectroscopy (FTIR)? What is the difference?

DRIFTS is used in both mid-IR and near-IR. In the mid-IR, DRIFTS requires the sample be blended with diluents like KBr, with 3-10% sample. This is typically undesirable as the sample is now mixed. However, DRIFTS is heavily used in catalysis research where powdered material is exposed to high temperature, elevated pressures, and mixtures of reactant gases. Several accessory suppliers make devices specific for this. In the near-IR, DRIFTS is used without dilution through direct measurement - many hand-held probes exist allowing analysis through a container wall (like plastic bags) meaning the sample can be analyzed without touching or contaminating it.

ATR involves making contact with the sample by forcing it into contact with a crystal. ATR generally does not require dilution and works well with solids like credit cards or car bumpers which would be tough in DRIFTS. ATR has, for the most part, displaced DRIFTS in the mid-IR except in special cases, while DRIFTS remains a method of choice in the near-IR world.

What are some subtleties and scenarios in inorganic applications for Fourier Transform Infrared Spectroscopy (FTIR)?

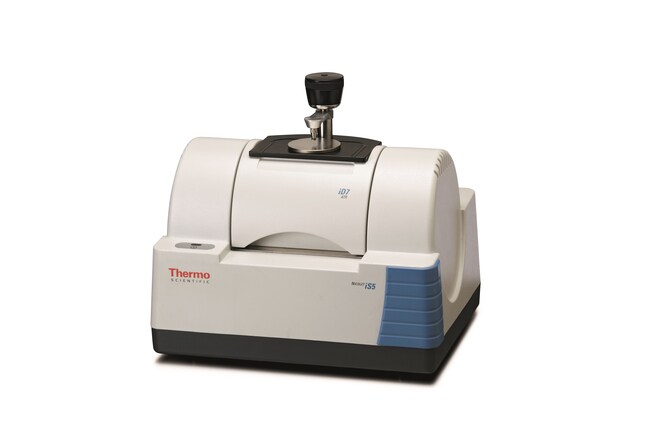

Fourier Transform Infrared Spectroscopy (FTIR) responds to a change in dipole moment, regardless of whether it is organic or inorganic. Metal oxides, carbonates, and carbonyls are good examples. The basic equation states that the wavenumber is proportional to the square root of the spring constant (bond strength) and one over the square root of the reduced mass. Simply put, as mass of the atoms involved in the bond goes up, the wavenumber goes down. Many inorganics have peaks below 400cm-1, such as ferrocene, acetylferrocene and cadmium oxide. This necessitates the use of “far-IR” optics. Many forensics users have found far-IR useful in identifying paint chips, due to their inorganic content. There are several ATR accessories that now permit far-IR ATR (mostly monolithic diamond devices). The Thermo Scientific Nicolet iS50 FTIR Spectrometer was designed to make far-IR performance trivial with a built-in ATR as well. Ultimately, if you have further interest in this area, you need to speak with an FTIR sales person to understand the capabilities and limitations.