Search

회로 편집 및 고속 프로토타이핑

기술 교체 시기를 놓치거나, 기술 교체에 뒤처지면 상당히 많은 비용을 대가로 지불해야 할 수 있으므로, 제품 개발과 출시까지의 기간을 단축하는 것은 매우 중요합니다. 각각의 새로운 기술 노드의 경우, 설계 및 통합 복잡성이 증가하므로 비용 관리, 일정 지연 방지, 제품 성능 및 기능 최적화를 위한 회로 편집 도구가 전략적으로 중요합니다.

올바른 도구, 워크플로우, 기술을 활용하는 회로 편집은 기업이 마스크 스핀을 줄이고 고속으로 프로토타이핑을 하며, 일정에 맞게 고객 설계를 지원하는 데 도움이 됩니다.

복잡한 반도체 회로 편집을 위해 특별히 설계된 Thermo Scientific Centrios 및 Centrios HX 회로 편집 시스템은 현재와 미래의 반도체 장치에 업계 최고의 정밀도, 제어 및 성능을 제공합니다.

Centrios HX 회로 편집 시스템

Centrios HX 회로 편집 시스템은 탁월한 편집 제어, 정밀도 및 안정성을 갖춘 최첨단 전면 및 후면 편집 기능을 위해 설계되었습니다.

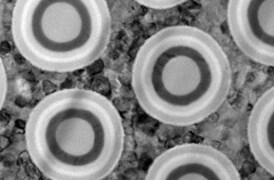

새로운 Thermo Scientific Celta 집속 이온 빔(FIB, Focused Ion Beam) 컬럼을 갖춘 Centrios HX 시스템은 낮은 빔 전류와 낮은 랜딩 에너지에서 높은 분해능을 제공하여 회로 손상을 최소화하면서 정확하게 편집할 수 있게 합니다. 광범위한 화학 물질 포트폴리오와 최신 FIB 기술을 갖춘 혁신적인 이중 노즐 가스 공급 시스템을 사용하는 Centrios HX 시스템은 업계 최고의 고정밀 에칭과 빠르고 효율적인 편집을 가능하게 합니다.

Centrios 회로 편집 시스템

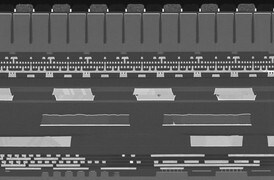

Centrios 회로 편집 시스템은 현장에서 입증된 Thermo Scientific Tomahawk WDR 이온 컬럼을 활용하여 강력한 성능을 제공하며 소유 비용이 경제적입니다. Centrios 시스템은 현재의 확립된 공정 노드를 위해 정밀한 전면 및 후면 편집, 고속 프로토타이핑, 실리콘 디버그 및 복구를 지원합니다.

이미징 및 밀링 분해능

Centrios 시스템 – 최신 빔 프로필 개선사항 및 현장에서 입증된 Thermo Scientific Tomahawk WDR FIB 컬럼을 사용하여 효과적이고 안전한 편집을 위해 낮은 빔 전류에서 고분해능을 구현합니다.

Centrios HX 시스템 – 최신 빔 프로파일 개선사항과 및 새로운 Thermo Scientific Celta FIB 컬럼을 사용하여 효과적이고 안전한 편집을 위해 낮은 빔 전류에서 더 높은 분해능을 구현합니다.

향상된 밀링 정밀도 및 제어

동시 이중 노즐 가스 공급 시스템 및 독점적인 가스 화학 포트폴리오를 사용하여 평면도/균일성, 장치 층 제거/에칭 중지, 높은 정확도로 고종횡비 바이어스(high-aspect-ratio vias) 생성.

전용 회로 편집 플랫폼

회로 편집을 위해 특별히 설계된 Centrios 및 Centrios HX 회로 편집 시스템은 기체 화학 물질 전달 등의 주요 구성 요소를 통합하여 수동 및 자동 응용 분야를 최적화합니다.

적은 운영 비용

탐색용 Thermo Scientific NEXS CAD 소프트웨어 및 Thermo Scientific iFAST 소프트웨어는 사용자 요구에 맞춰 자동화를 할 수 있어 효율성과 사용 편의성을 향상시킵니다.

Centrios 시스템 | Centrios HX 시스템 | |

이온 컬럼 |

|

|

이미지 분해능 |

|

|

빔 전류 |

|

|

스테이지 |

| |

엔드-포인트(end-point) 검출 |

|

반도체 경로탐색(Pathfinding) 및 개발

고성능 반도체 장치의 제조에 필요한 실행 가능한 솔루션과 설계 방법을 확인하기 위한 고급 전자 현미경 검사, 집속 이온빔 및 관련 분석 기법.

반도체 불량 분석

반도체 장치 구조가 점점 복잡해짐에 따라 숨겨진 장애 유발 결함이 더 많아지고 있습니다. 당사의 차세대 워크플로우는 사용자가 수율, 성능, 신뢰성에 영향을 미치는 미세한 전기 문제를 로컬화하고 특성을 분석하는 데 도움을 줍니다.

회로 편집

새로운 가스 공급 시스템과 광범위한 화학 및 집속 이온 빔 기술이 결합된 고급 전용 회로 편집 및 나노 프로토타이핑 솔루션은, 반도체 장치 개발을 위한 탁월한 제어 및 정밀도를 제공합니다.

회로 편집

새로운 가스 공급 시스템과 광범위한 화학 및 집속 이온 빔 기술이 결합된 고급 전용 회로 편집 및 나노 프로토타이핑 솔루션은, 반도체 장치 개발을 위한 탁월한 제어 및 정밀도를 제공합니다.