Search

Circuit Edit Systems

Centrios Circuit Edit Systems

Semiconductor circuit prototyping, debug, and circuit repair using the Centrios and Centrios HX Circuit Edit Systems.

Join the Conversation

Semiconductor circuit edit and circuit prototyping

Accelerating product development and time-to-market are critical as missing a technology window, or falling behind, can be extremely costly. As design and integration complexity rise with each new technology node, circuit edit tools are strategically important for managing costs, avoiding schedule delays, and optimizing product performance and functionality.

With the right tools, workflows and techniques, circuit editing can help companies reduce mask spins, rapidly prototype, and support customer design in schedules.

Designed specifically for complex semiconductor circuit editing, the Thermo Scientific Centrios and Centrios HX Circuit Edit Systems provide industry leading precision, control, and performance for the semiconductor devices of today and tomorrow.

Centrios HX Circuit Edit System

The Centrios HX Circuit Edit System is designed for the most advanced front and backside edit capabilities with unparalleled editing control, precision, and stability.

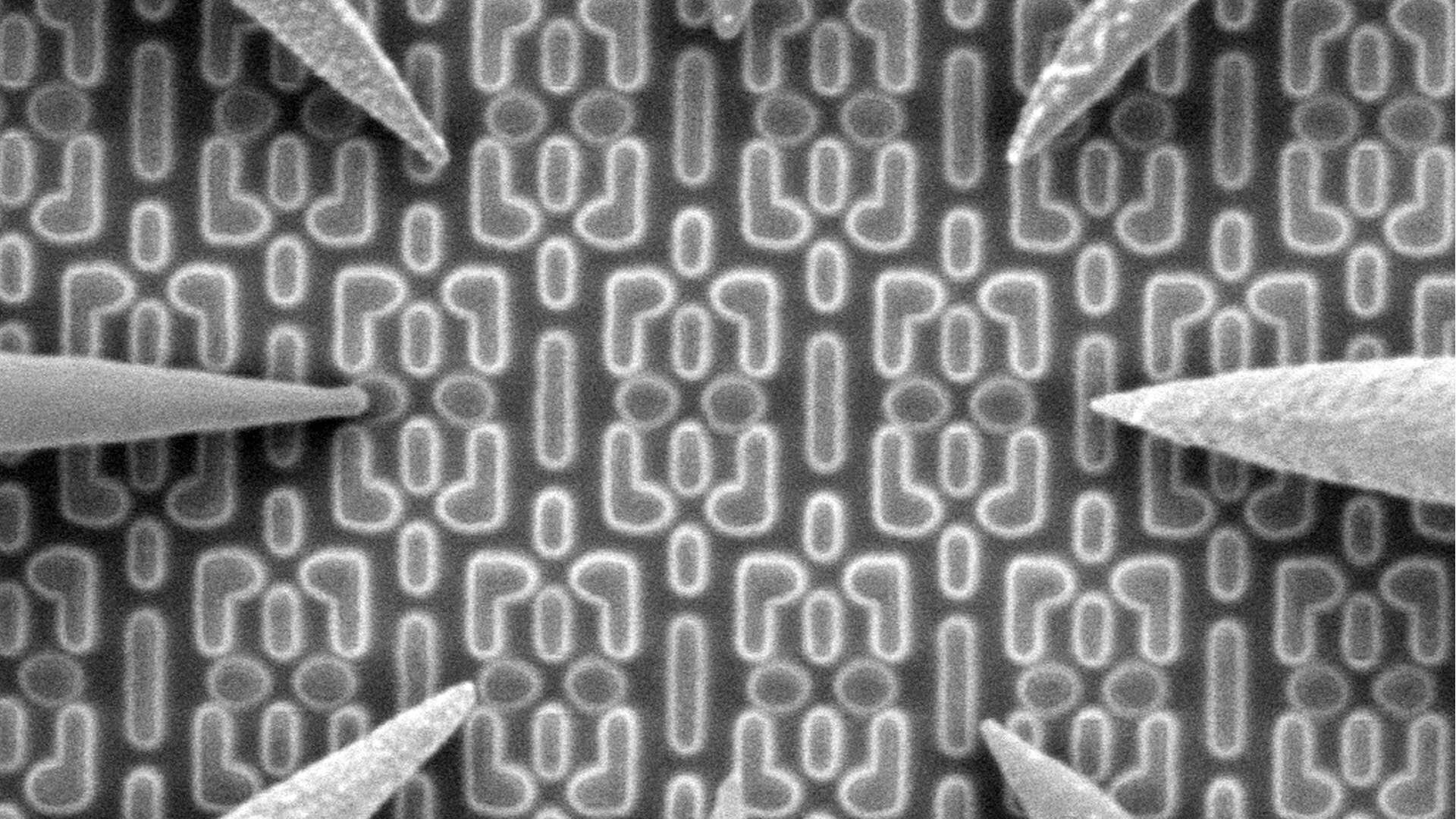

Featuring the new Thermo Scientific Celta Focused Ion Beam (FIB) Column, the Centrios HX System delivers high resolution at low beam currents and low landing energies, allowing you to perform edits accurately and with minimum circuit damage. Using an innovative dual-nozzle gas-delivery system with the broadest portfolio of chemistries, and the latest FIB technology, the Centrios HX System enables industry leading high-precision etching and fast, efficient editing.

Enable working device prototypes and speed up product development cycles with the Centrios HX Circut Edit System.

Centrios Circuit Edit System

The Centrios Circuit Edit System utilizes the field-proven Thermo Scientific Tomahawk WDR Ion Column, providing strong performance and cost of ownership. The Centrios System enables precise front and backside editing, rapid prototyping, and silicon debug and repair for today’s established process nodes.

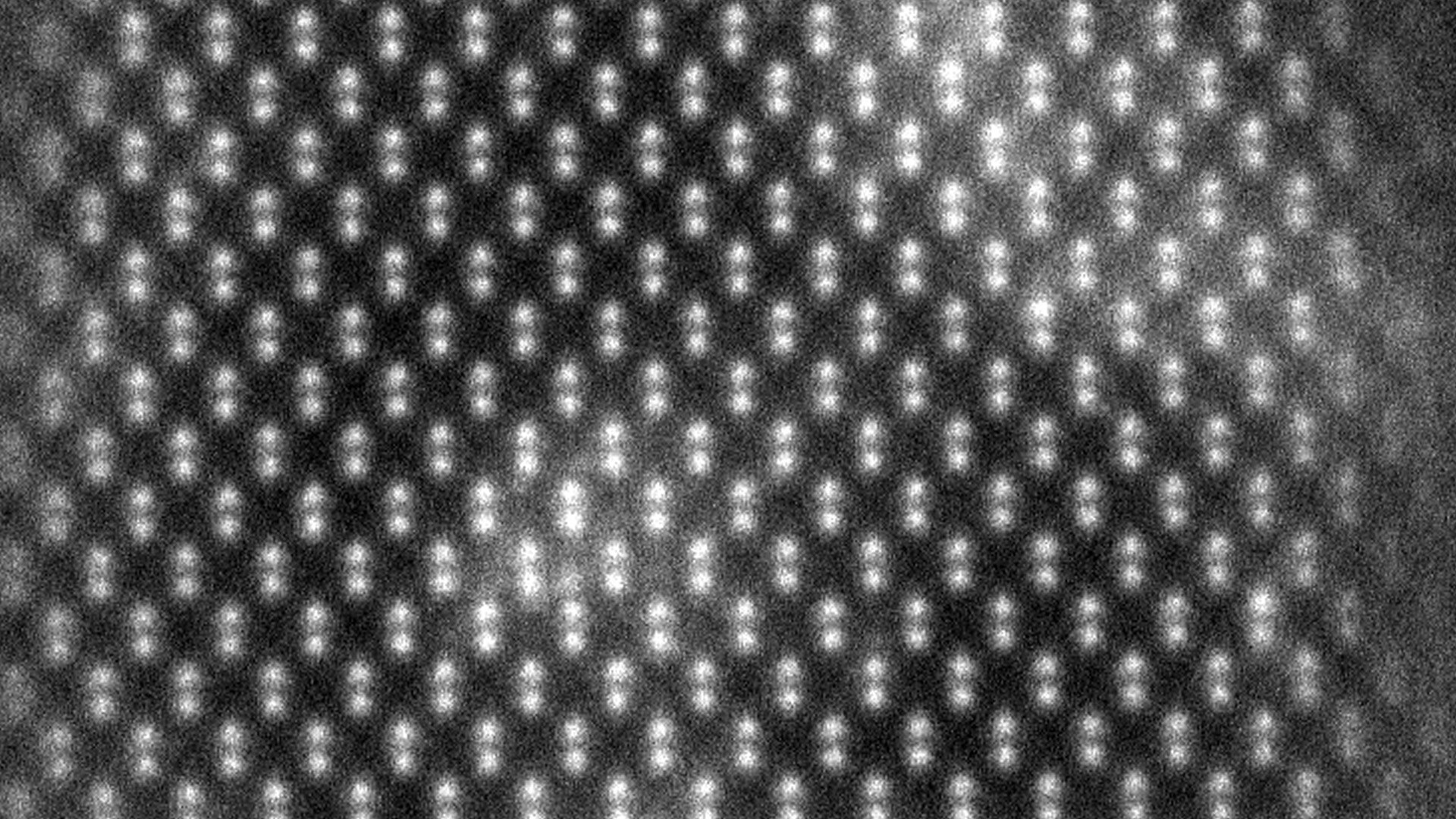

Imaging and milling resolution

Centrios System – High resolution at low beam currents for effective, safe edits using the field-proven Thermo Scientific Tomahawk WDR FIB Column.

Centrios HX System – 25% higher resolution at 4X lower beam currents for effective, safe edits using the new Thermo Scientific Celta FIB Column with the latest beam profile improvements.

Enhanced milling precision and control

Planarity/uniformity, delayering/etch stopping, and high-acuity creation of high-aspect-ratio vias using a simultaneous dual-nozzle gas delivery system and proprietary gas chemistry portfolio.

Dedicated circuit edit platform

Designed specifically for circuit editing, the Centrios and Centrios HX Circuit Edit Systems integrate key components, such as gas chemistry delivery, enabling optimized manual and automated applications.

Low cost of operation

Thermo Scientific NEXS CAD Software for navigation and Thermo Scientific iFAST Software customize automation for improve efficiency and ease of use.

Centrios System | Centrios HX System | |

Ion column |

|

|

Image resolution |

|

|

Beam current |

|

|

Stage |

| |

End-point detection |

|

Fundamentals of Circuit Edit eBook

While circuit editing is a well-established technique, it can be especially difficult for those who are new to it. To help you get started, we asked our circuit edit customers what they wish they had known when they started doing FIB circuit edit and collected their feedback, as well as input from our team of experts, in our new eBook: Fundamentals of Circuit Edit. The eBook includes:

- A definition of circuit edit

- An overview of focused ion beams

- Circuit edit tips from experienced practitioners

- Descriptions of key circuit edit tools and solutions

Fundamentals of Circuit Edit eBook

While circuit editing is a well-established technique, it can be especially difficult for those who are new to it. To help you get started, we asked our circuit edit customers what they wish they had known when they started doing FIB circuit edit and collected their feedback, as well as input from our team of experts, in our new eBook: Fundamentals of Circuit Edit. The eBook includes:

- A definition of circuit edit

- An overview of focused ion beams

- Circuit edit tips from experienced practitioners

- Descriptions of key circuit edit tools and solutions

Semiconductor research and development

Innovation starts with research and development. Learn more about solutions to help you understand innovative structures and materials at the atomic level.

Semiconductor Failure Analysis

Complex semiconductor device structures result in more places for defects to hide. Learn more about failure analysis solutions to isolate, analyze, and repair defects.

Circuit Edit

Advanced, dedicated circuit edit and nanoprototyping solutions, which combine novel gas-delivery systems with a broad portfolio of chemistries and focused ion beam technology, offer unparalleled control and precision for semiconductor device development.

Circuit Edit

Advanced, dedicated circuit edit and nanoprototyping solutions, which combine novel gas-delivery systems with a broad portfolio of chemistries and focused ion beam technology, offer unparalleled control and precision for semiconductor device development.

Electron microscopy services for

semiconductors

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.