Search

ELECTRICAL FAILURE ANALYSIS SYSTEMS

Meridian 4 System

Photon emission microscopy and laser scanning microscopy for electrical fault localization.

Join the Conversation

The ability to improve yield and reliability includes detailed defect analysis. Design debugging of marginal failures can be more challenging due to voltage or timing issues within the device. Determining the root cause of parametric failure requires isolation of its location at both the circuit level and the device level without damaging the device or obscuring the defects.

The Thermo Scientific Meridian 4 System is the preferred choice for developers of advanced, low-voltage, high-density semiconductor devices requiring performance and the ability to diagnose wide-ranging failure modes, including parametric failures and those resulting from design-process marginalities.

Advanced Thermo Scientific Sierra User Environment and Analysis Software includes the ability to construct high-quality, high-magnification image mosaics. Individual high-magnification images are acquired and then seamlessly integrated to form a high-resolution image of the device over a large field of view.

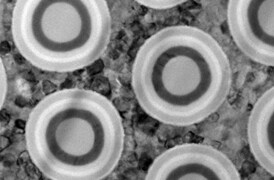

Photon emission microscopy for isolating FEOL issues

- Standard InGaAs or extended-wavelength DBX photon emission detection options for low-voltage devices and weak emission signatures requiring high sensitivity

- Low noise with unmatched signal-to-noise ratios for rapid, transistor-level fault detection

- Industry-leading results on sub-0.5 Vdd devices with the DBX configuration

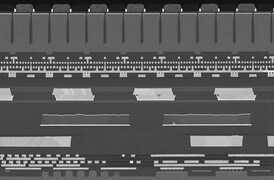

Laser scanning microscopy for static and dynamic failure analysis

- High-resolution, high-contrast confocal laser scanning system

- Static Laser Stimulation (SLS) applications including OBIRCH, OBIC, and Seebeck Effect Imaging (SEI)

- Defect isolation and characterization under dynamic test conditions for advanced devices

- Soft defect localization (SDL), laser voltage imaging (LVI), and laser voltage probing (LVP) dynamic techniques enable localization of parametric failures, debug design and timing issues, and map transistor frequencies

- Optional Time-resolved LADA for critical timing analysis

TR-LADA for Dynamic OFI

Preserving sensitive circuit areas while delivering greater defect localization capabilities is what the new TR-LADA option can do for your Meridian Optical Fault Isolation system.

TR-LADA for Dynamic OFI

Preserving sensitive circuit areas while delivering greater defect localization capabilities is what the new TR-LADA option can do for your Meridian Optical Fault Isolation system.

Desarrollo y trazabilidad de semiconductores

Microscopía electrónica avanzada, haz de iones enfocado y técnicas analíticas asociadas para identificar soluciones viables y métodos de diseño para la fabricación de dispositivos semiconductores de alto rendimiento.

Análisis de fallos de semiconductores

Las estructuras de dispositivos semiconductores cada vez más complejas dan lugar a que existan más ubicaciones en las que se oculten los defectos inducidos por fallos. Nuestros flujos de trabajo de última generación le ayudarán a localizar y caracterizar los sutiles problemas eléctricos que afectan a la producción, al rendimiento y a la fiabilidad.

Aislamiento de fallo óptico

Los diseños cada vez más complejos complican el aislamiento de fallos y defectos en la fabricación de semiconductores. Las técnicas de aislamiento óptico de fallos le permiten analizar el rendimiento de los dispositivos activos eléctricamente para localizar defectos críticos que causan fallos en el dispositivo.

Aislamiento de fallo óptico

Los diseños cada vez más complejos complican el aislamiento de fallos y defectos en la fabricación de semiconductores. Las técnicas de aislamiento óptico de fallos le permiten analizar el rendimiento de los dispositivos activos eléctricamente para localizar defectos críticos que causan fallos en el dispositivo.

Servicios de microscopía electrónica para

Semiconductores

Para garantizar un rendimiento óptimo del sistema, le proporcionamos acceso a una red de expertos de primer nivel en servicios de campo, asistencia técnica y piezas de repuesto certificadas.