Search

ELECTRICAL FAILURE ANALYSIS SYSTEMS

Meridian WS-DP System

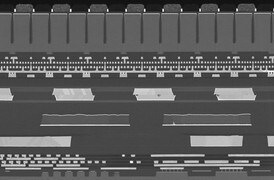

Electrical fault analysis of full semiconductor wafers up to 300mm under production conditions.

Join the Conversation

With time-to-yield being critical to profitability, it is too costly for advanced foundries, integrated device manufacturers and fabless companies to wait until after dicing and packaging to identify the source of electrical faults. The Thermo Scientific Meridian WS-DP system enables faster defect localization by using production testers, load boards, and probe cards.

All diagnostic options from the Meridian product line are available for the Meridian WS-DP, including: LVx, emission, LADA, and OBIRCH.

The Meridian WS-DP system provides:

- Ability to identify systematic defects

- Significantly increased electrical measurement throughput

- Improved defect localization success rate

- Reduced physical analysis time

Capabilities:

- Standard InGaAs-based emission detection or

- High sensitivity extended-wavelength DBX-based emission detection

- Patented, industry-proven "Point & Click" Solid Immersion Lens (SIL)

- Rapid die-to-die indexing

- Dynamic fault coverage with high-speed ATE interface

- Laser scanning microscope (LSM) for static and dynamic analysis

- Compatibility with most popular third-party EDA applications

Laser voltage imaging

Laser voltage imaging (LVI), shows the physical locations of transistors that are active at a specific frequency on the Meridian WS-DP system.

CW laser voltage probing

Continuous wave laser voltage probing (CW-LVP) acquires functional waveform data on the Meridian WS-DP system.

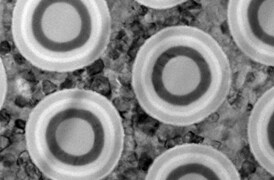

Photon emission microscopy

Photon emission microscopy (PEM) on the Meridian platform is based on an optimized combination of a high sensitivity InGaAs or DBX camera and high numerical aperture (NA) aberration-corrected optics. The Meridian WS-DP system provides high-resolution through-silicon imaging for backside device analysis. Low noise and high sensitivity enable emission data with unmatched signal-to-noise ratios, resulting in rapid, transistor-level fault detection. The DBX configuration provides industry-leading results even on sub-0.5 Vdd devices.

| Mechanical | ATE compatibility | Commercially available ATE testers & customized solutions |

| Probe Card / Load Board |

| |

| Probe pin count | Probe arrays of <100 to >10,000 pins | |

| Wafer Stage vacuum | 20lbs vacuum force for wafer stability | |

| Motion Control | Die-to-die stepping | Supported and integrated into Sierra software |

| Platen motion |

| |

| Wafer / DUT supported |

| |

| XYZ microscope stage accuracy | 1 um | |

| XY wafer stage accuracy | 5um | |

| Die size compatibility | A wide range of solutions |

Semiconductor Pathfinding and Research

Advanced electron microscopy, focused ion beam, and associated analytical techniques for identifying viable solutions and design methods for the fabrication of high-performance semiconductor devices.

Semiconductor Failure Analysis

Increasingly complex semiconductor device structures result in more places for failure-inducing defects to hide. Our next-generation workflows help you localize and characterize subtle electrical issues that affect yield, performance, and reliability.

Optical Fault Isolation

Increasingly complex designs complicate fault and defect isolation in semiconductor manufacturing. Optical fault isolation techniques allow you to analyze the performance of electrically active devices to locate critical defects that cause device failure.

Optical Fault Isolation

Increasingly complex designs complicate fault and defect isolation in semiconductor manufacturing. Optical fault isolation techniques allow you to analyze the performance of electrically active devices to locate critical defects that cause device failure.

Electron microscopy services for

semiconductors

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.