Search

Autoscript 4 Software for scanning electron microscopy and FIB SEM

Automation software packages for electron/ion microscopy like Thermo Scientific Maps and Thermo Scientific Auto Slice and View are great for making collection of standard imaging techniques easy. However, working to achieve cutting edge research goals or to meet specific industrial requirements is seldom standard.

Industrial automation as well as fundamental research often requires advanced techniques for imaging and analysis that cannot be covered in the scope of general purpose software.

Automated electron microscopy and FIB SEM imaging

Thermo Scientific AutoScript 4 Software is the customization toolkit for electron and ion microscopy. Built around Python, Autoscript Software provides you the power to automate imaging and associated processing pipelines built to solve specific research questions.

AutoScript Software:

- Provides a direct link between research needs and microscope automation

- Enables improved reproducibility and accuracy

- Focuses time on the microscope for higher throughput

Integrated IDE

An integrated development environment (IDE) makes it easy to get up and running with AutoScript Software. Object browsing and syntax tools with auto completion are all included to ensure a rich user experience and rapid, consistent scripting framework.

Python

Harness the power of your microscope using the most popular scientific programming language. Autoscript Software is built on Python 3.5 and includes a number of pre-installed libraries for scientific computing, data analysis, data visualization, image processing, and machine learning.

Scripting toolbox

AutoScript 4 Software comes bundled with a set of commonly needed, prebuilt routines. Not starting from scratch means more time to focus on developing the scripts that define the unique workflow for your research.

| Supported microscope control methods |

|

| Common packages |

|

| Application examples |

|

| Compatibility |

|

Control de proceso

La industria moderna exige un alto rendimiento con una calidad superior, un equilibrio que se mantiene a través de un control de procesos sólido. Las herramientas SEM y TEM con software de automatización exclusivo proporcionan información rápida y multiescala para la supervisión y la mejora de procesos.

Control de calidad

El control y garantía de calidad son esenciales en la industria moderna. Ofrecemos una gama de herramientas de EM y espectroscopía para el análisis multiescala y multimodal de defectos, lo que le permite tomar decisiones fiables e informadas para el control y la mejora de procesos.

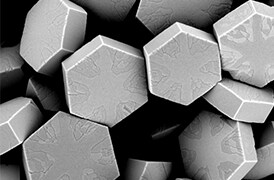

Investigación sobre materiales fundamentales

Se investigan nuevos materiales a escalas cada vez más pequeñas para lograr el máximo control de sus propiedades físicas y químicas. La microscopía electrónica proporciona a los investigadores información clave sobre una amplia variedad de características materiales a escala nanométrica.

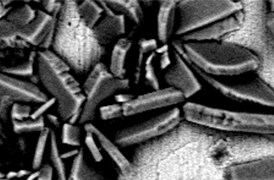

Caracterización de materiales en 3D

El desarrollo de materiales suele requerir caracterización en 3D en varias escalas. Los instrumentos DualBeam permiten el corte en secciones en serie de grandes volúmenes y la posterior adquisición de imágenes SEM a escala de nanómetro, las cuales se pueden procesar en reconstrucciones 3D de la muestra de alta calidad.

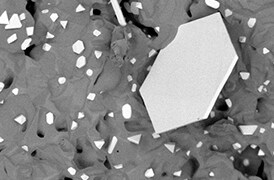

Análisis de escala múltiple

Los novedosos materiales se deben analizar a una resolución cada vez mayor, manteniendo el contexto más amplio de la muestra. El análisis de escala múltiple permite la correlación de varias herramientas y modalidades de obtención de imágenes, tales como microTC de rayos X, DualBeam, PFIB láser, SEM y TEM.

Caracterización de materiales en 3D

El desarrollo de materiales suele requerir caracterización en 3D en varias escalas. Los instrumentos DualBeam permiten el corte en secciones en serie de grandes volúmenes y la posterior adquisición de imágenes SEM a escala de nanómetro, las cuales se pueden procesar en reconstrucciones 3D de la muestra de alta calidad.

Análisis de escala múltiple

Los novedosos materiales se deben analizar a una resolución cada vez mayor, manteniendo el contexto más amplio de la muestra. El análisis de escala múltiple permite la correlación de varias herramientas y modalidades de obtención de imágenes, tales como microTC de rayos X, DualBeam, PFIB láser, SEM y TEM.

Servicios de microscopía electrónica para

la ciencia de materiales

Para garantizar un rendimiento óptimo del sistema, le proporcionamos acceso a una red de expertos de primer nivel en servicios de campo, asistencia técnica y piezas de repuesto certificadas.