Search

Materials Science

Automotive Materials Testing

Automotive parts testing using scanning electron microscopy and spectroscopy.

Join the conversation

Automotive parts testing

Today’s automotive parts have seen incredible advances in the functionality and reliability of transmissions, fuel injection systems, power trains, and braking systems. These improvements are the result of fundamental advances in the materials used in automotive manufacturing, including novel, increasingly complex steel, glass, ceramic, and polymer materials.

Automotive materials testing

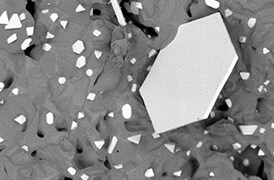

These improvements, however, also come with new challenges. For example, high-precision automotive parts are more susceptible to residual, micron-size particulate contamination, which results in component, or potentially even system, failure. To make matters worse, current analytical techniques are often inadequate (too low resolution) to help engineers determine the cause of these failures.

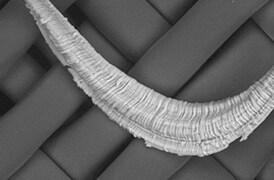

New vehicles also undergo extensive testing to ensure the production of reliable, quality automobiles along with further improvements to current materials and processes. For instance, the increasing demand for affordable, fuel-efficient tires requires better test methods to develop and study new rubber formulations. The next generation of rubber compounds has to reduce road resistance while still yielding a quality end product in order to substantially impact fuel efficiency. This starts with detailed analytical assessment using techniques such as electron microscopy.

Automotive quality control

Thermo Fisher Scientific provides a range of instrumentation and software that simplifies your automotive materials analysis. These tools also have the potential to greatly reduce production times as you bring the quality control process in-house. By no longer relying on outsourcing for your QC analysis, production-cycle time can decrease by up to ten-fold.

Watch on-demand: Particle Analysis Applications Using Desktop SEM Webinar Series

In each on-demand webinar, our expert will focus on one particular analysis application and how the Phenom ParticleX Desktop SEM overcomes some of the most common challenges. See the abstracts for individual sessions below.

- How to certify your NCM powder quality with SEM+EDS

- Electron-microscope-grade cleanliness in electronics

- Speed up your automated gunshot residue analysis

- Technical cleanliness analysis with an SEM: Why?

- Understand your steel with automated inclusion analysis

- One tool for complete AM powder characterization

Watch on-demand: Particle Analysis Applications Using Desktop SEM Webinar Series

In each on-demand webinar, our expert will focus on one particular analysis application and how the Phenom ParticleX Desktop SEM overcomes some of the most common challenges. See the abstracts for individual sessions below.

- How to certify your NCM powder quality with SEM+EDS

- Electron-microscope-grade cleanliness in electronics

- Speed up your automated gunshot residue analysis

- Technical cleanliness analysis with an SEM: Why?

- Understand your steel with automated inclusion analysis

- One tool for complete AM powder characterization

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Technical Cleanliness

More than ever, modern manufacturing necessitates reliable, quality components. With scanning electron microscopy, parts cleanliness analysis can be brought inhouse, providing you with a broad range of analytical data and shortening your production cycle.

Atomic-Scale Elemental Mapping with EDS

Atomic-resolution EDS provides unparalleled chemical context for materials analysis by differentiating the elemental identity of individual atoms. When combined with high-resolution TEM, it is possible to observe the precise organization of atoms in a sample.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

Atomic-Scale Elemental Mapping with EDS

Atomic-resolution EDS provides unparalleled chemical context for materials analysis by differentiating the elemental identity of individual atoms. When combined with high-resolution TEM, it is possible to observe the precise organization of atoms in a sample.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.