Search

Materials Science

DualBeam FIB Cross Sectioning

FIB cross section generation with DualBeam tools for automated and high throughput subsurface characterization.

Join the conversation

performed on a Helios G4 PFIB DualBeam.

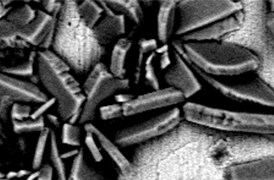

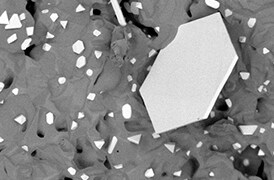

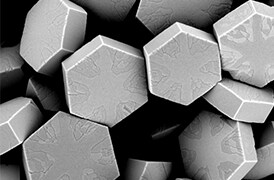

Modern materials characterization is increasingly reliant on sub-surface characterization for a more comprehensive understanding of the material’s structure and physical properties. Cross-sectioning with a DualBeam instrument, which combines a focused ion beam with a scanning electron microscope (FIB-SEM), allows you to mill the material with FIB and perform high-resolution SEM imaging at nanometer scale. In failure analysis, for instance, this allows for defects to be located under the surface, making DualBeams instruments ideal for identification of the root cause of failures.

Along with high-resolution SEM imaging, cross-section characterization on the DualBeam can be expanded with back-scattered electron (BSE) imaging for maximum materials contrast, energy-dispersive X-ray spectroscopy (EDS) for compositional information, and electron backscatter diffraction (EBSD) for microstructural and crystallographic information.

Additionally, with the introduction of the Thermo Scientific Helios 5 Hydra DualBeam, we now offer the flexibility of argon, oxygen, xenon, and nitrogen ion species in one instrument, allowing you to choose the best FIB type for each of your experiments. Xenon ions are well suited for high-throughput removal of various materials, like metals and ceramics, whereas oxygen ions provide superior milling quality for carbon-based samples. In case extremely large volume characterization is needed, the Thermo Scientific Helios 5 Laser PFIB System is an additional solution. It enables high-throughput cross-sectioning up to millimeter scale, as well as processing of materials that are typically challenging for ion beams (e.g. charging or beam sensitive samples). We combine these unique DualBeam capabilities with our versatile software solutions to bring you a range of workflows for advanced 3D characterization and high-resolution analysis at the nanometer scale.

Control de proceso

La industria moderna exige un alto rendimiento con una calidad superior, un equilibrio que se mantiene a través de un control de procesos sólido. Las herramientas SEM y TEM con software de automatización exclusivo proporcionan información rápida y multiescala para la supervisión y la mejora de procesos.

Control de calidad

El control y garantía de calidad son esenciales en la industria moderna. Ofrecemos una gama de herramientas de EM y espectroscopía para el análisis multiescala y multimodal de defectos, lo que le permite tomar decisiones fiables e informadas para el control y la mejora de procesos.

Investigación sobre materiales fundamentales

Se investigan nuevos materiales a escalas cada vez más pequeñas para lograr el máximo control de sus propiedades físicas y químicas. La microscopía electrónica proporciona a los investigadores información clave sobre una amplia variedad de características materiales a escala nanométrica.

Investigación de baterías

El desarrollo de baterías se realiza mediante análisis multiescala con microCT, SEM y TEM, espectroscopía Raman, XPS y visualización y análisis 3D digital. Aprenda cómo este enfoque proporciona la información estructural y química necesaria para crear mejores baterías.

Gas y petróleo

A medida que la demanda de petróleo y gas continúa, existe la necesidad constante de una extracción eficiente y eficaz de hidrocarburos. Thermo Fisher Scientific ofrece una amplia gama de soluciones de microscopía y espectroscopía para una gran variedad de aplicaciones de la ciencia del petróleo.

Investigación sobre metales

La producción eficaz de metales requiere un control preciso de las inclusiones y precipitados. Nuestras herramientas automatizadas pueden realizar varias tareas cruciales para el análisis de metales, incluyendo el recuento de nanopartículas, el análisis químico EDS y la preparación de muestras de TEM.

Investigación sobre catálisis

Los catalizadores son cruciales para la mayoría de los procesos industriales modernos. Su eficacia depende de la composición microscópica y la morfología de las partículas catalíticas; EM con EDS es ideal para estudiar estas propiedades.

Investigación sobre polímeros

La microestructura polimérica determina las características y el rendimiento del material a granel. La microscopía electrónica permite un análisis exhaustivo en microescala de la morfología y composición de los polímeros para aplicaciones de control de calidad e I+D.

Investigación geológica

Las ciencias geológicas están basadas en la observación uniforme y precisa de múltiples escalas de características dentro de las muestras de roca. SEM-EDS, combinado con software de automatización, permite el análisis directo a gran escala de la composición de la textura y los minerales para la investigación de la petrología y la mineralogía.

Servicios de microscopía electrónica para

la ciencia de materiales

Para garantizar un rendimiento óptimo del sistema, le proporcionamos acceso a una red de expertos de primer nivel en servicios de campo, asistencia técnica y piezas de repuesto certificadas.