The most popular detector for HPLC/UHPLC analysis is the UV-Vis detector. But what happens if your analytes don’t have a chromophore and cannot be detected by this approach?

You’ll likely turn to a near-universal detector such as the Charged Aerosol Detector (CAD) and Evaporative Light Scattering Detector (ELSD). These detectors can measure non-volatile and many semi-volatile compounds whether or not a chromophore is present.

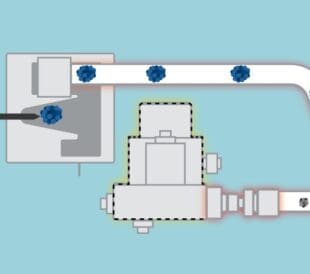

Both CAD and ELSD are evaporative aerosol detectors that differentiate analyte from mobile phase-based on relative volatility. As a result, both have a similar detection scope (non-volatile and semi-volatile analytes) and the same basic operational requirements:

- Volatile mobile phases and additives with the highest quality of minimal residue after evaporation

- A steady stream of purified gas, usually nitrogen

- Stable columns devoid of bleed

Now, if you’re familiar with this topic you likely know there’s an ongoing debate among chromatographers over which detector is the better choice.

Let’s dive into the science of each detection method to learn more

The charged aerosol measurement is fundamentally AND consistently more sensitive than light scattering and has a major impact on the overall analytical performance.

Here’s why:

- In the CAD, particles acquire a charge by collision with ionized nitrogen gas and charging is independent of chemical structure. The charge on the particle is then measured using a highly sensitive electrometer and your signal is proportional to the particle size (mass of the analyte). The greater the amount of analyte present, the larger the particle size and the more charge carried, which equals a higher response.

- For ELSD, light scattered by the dried aerosol particles is used to determine the amount of analyte present. Like CAD, the signal is also proportional to particle size. But this relationship is much more complex, as the magnitude of scattered light varies exponentially depending on particle size, resulting in complex sigmoidal response curves. With ELSD, little to no signal is obtained for smaller particles and inter-analyte properties — like refractive index, light absorption, and fluorescence — can impact response.

So even though CAD and ELSD share functional similarities, the mechanism by which the detectors measure analyte mass differs markedly. As the literature demonstrates, CAD tends to outperform ELSD regarding dynamic and linear range, sensitivity, precision and accuracy.

Top ways CAD beats ELSD1-23, backed by published data

1. Practically speaking, CAD provides 10-fold or better limits of detection than ELSD

This quantitative difference in the reported limits of detection (LOD) between the two detectors derives from particle size.

CAD is much more sensitive than ELSD because smaller particles (lesser amounts of analyte) are quantitatively detected. For ELSD, particles must be large enough to efficiently scatter light, and you get little to no signal for particle diameters less than about 50 nm.

Unlike ELSD, CAD maintains good sensitivity for particles as small as 10 nm.

2. CAD has an inherently wider dynamic range, typically two times greater than ELSD

A wide dynamic range is essential when measuring low levels of an analyte in the presence of another at a much higher level, like for impurity analysis.

The CAD has an inherent dynamic range of four orders of magnitude, and you can readily measure analytes in the same sample with varying concentration ranges, all without having to reanalyze the sample at different gain ranges.

The ELSD is much different as photomultipliers or photodiodes used to measure light scattering have a relatively small dynamic range, usually around two orders of magnitude. Various processing techniques are applied to try and extend the dynamic range, which the CAD doesn’t need.

3. CAD response is sufficiently linear over approximately two orders of magnitude, so you can use linear calibration models for many methods

The CAD response is linear over two orders of magnitude and has a dynamic range of four orders of magnitude. The ELSD response is typically linear over just one order of magnitude, with a dynamic range of two orders of magnitude. As a result, most analyses require logarithmic transformation before linear calibration, which adds unnecessary complexity, especially for method validation and use in regulated labs.

Furthermore, with CAD you can use a unique data acquisition parameter called the Power Function Value (PFV) setting to optimize the range over which the response is sufficiently linear for a given method and range of quantitation.

Since non-linear response also affects peak shape and signal-to-noise ratio, optimizing the PFV also provides a more accurate and simplified calculation of measured chromatographic resolution and limits of detection.

4. CAD response is uniform and independent of chemical structure, which powers standard-free quantitation

Response uniformity (consistency) is important when quantifying analytes for which individual calibration standards are unavailable, like drug discovery, impurity analysis, and compound library management.

The CAD is more accurate than ELSD for standard free quantification for two big reasons: Because the inter-analyte response across a wide range of chemical structures is similar and you can apply an inverse gradient to compensate for response changes during gradient elution.

In contrast, the physicochemical properties of your analytes may have more of an impact on ELSD response than CAD. For example, analyte properties including refractive index, light absorption, and fluorescence, are all reported to affect ELSD response.

Also, with ELSD there is a greater chance that the peak you select as a surrogate standard may not behave in the same way as your peaks of interest.

5. The complex shape of ELSD response curves can often lead to additional limitations and greater inaccuracies

The response curves for CAD and ELSD are quite opposite (Figure 1). Throughout the full range, an ELSD response curve shows dramatic changes in both the degree and the direction of curvature. These sharp changes are often associated with imprecision and inaccuracy because the magnitude of scattered light varies exponentially with particle size, resulting in a complex sigmoidal response curve.

Much of this complex behavior is explained by considering the expected signal from smaller aerosol particles, those less than approximately 50 nm, which predominate at lower analyte concentrations and edges of any chromatographic peak.

For this particle range, a decrease in concentration that causes a two-fold decrease in particle diameter should, in theory, result in a ~64-fold decrease in light scattering intensity, which is proportional to 106 for Rayleigh scattering. This loss in sensitivity is often described as a sudden disappearance or dramatic drop off in the ELSD signal.

For CAD, the same decrease in diameter should result in only about a two-fold decrease in charge per particle, giving rise to a much simpler and closer-to-linear relationship, and many direct comparison studies show CAD provides better precision and accuracy than ELSD.

6. ELSD is not a linear detector and “estimated” LODs and LOQs you derive from high-level standards are meaningless

While common practice is to estimate the limits of detection (LOD) or limits of quantification (LOQ) for a linear detector by extrapolation of signal-to-noise ratio from higher-level standards, any estimates you derive this way with ELSD are often quite misleading.

The reason is due to the dramatic ”drop off’ in ELSD response for smaller particles, so you should determine LOD and LOQ by actual analysis of diminishingly low levels of analyte.

Assessment of linearity should include a closer examination of accuracy or recovery, especially at lower concentrations.

Explore how your lab can benefit from using charged aerosol detection

As you can see, CAD presents many analytical advantages over ELSD, which is directly tied to the benefits of electrical aerosol detection versus light scattering, respectively.

Learn how you can accelerate drug discovery and improve formulation stability with HPLC-CAD technology today.

Literature references

- Sensitive Determination of Saponins in Radix et Rhizoma Notoginseng by Charged Aerosol Detector Coupled with HPLC

- Comparison between evaporative light scattering detection and charged aerosol detection for the analysis of saikosaponins

- Comparison of universal detectors for high-temperature micro liquid chromatography

- Control of impurities in L‐aspartic acid and L‐alanine by high‐performance liquid chromatography coupled with a corona charged aerosol detector

- Alternatives to amino acid analysis for the purity control of pharmaceutical grade L-alanine

- Impurity Control in Topiramate with High Performance Liquid Chromatography

- Comparison of two aerosol‐based detectors for the analysis of gabapentin in pharmaceutical formulations by hydrophilic interaction chromatography

- Size exclusion chromatography with Corona charged aerosol detector for the analysis of polyethylene glycol polymer

- A non-derivative method for the quantitative analysis of isosteroidal alkaloids from Fritillaria by high performance liquid chromatography combined with charged aerosol detection

- Evaluation of charged aerosol detection (CAD) as a complementary technique for high‐throughput LC‐MS‐UV‐ELSD analysis of drug discovery screening libraries

- Quantitative study of the stratum corneum lipid classes by normal phase liquid chromatography: comparison between two universal detectors

- Aerosol based detectors for the investigation of phospholipid hydrolysis in a pharmaceutical suspension formulation

- Polyketide analysis using mass spectrometry, evaporative light scattering, and charged aerosol detector systems

- Comparison between charged aerosol detection and light scattering detection for the analysis of Leishmania membrane phospholipids

- Recent applications of the Charged Aerosol Detector for liquid chromatography in drug quality control

- Comparison of ultraviolet detection, evaporative light scattering detection and charged aerosol detection methods for liquid‐chromatographic determination of anti‐diabetic drugs

- Quantitative comparison of a corona‐charged aerosol detector and an evaporative light‐ scattering detector for the analysis of a synthetic polymer by supercritical fluid chromatography

- Review of operating principle and applications of the charged aerosol detector

- Performance evaluation of evaporative light scattering detection and charged aerosol detection in reversed phase liquid chromatography

- Performance evaluation of charged aerosol and evaporative light scattering detection for the determination of ginsenosides by LC

- HPLC determinations of enantiomeric ratios

- Comparison of ELSD and CAD methods for determination of phosphatidylcholine content in polyene phosphatidycholine injection

- Kiser, M. M.; Dolan, J. W. Selecting the best curve fit. LC GC North America 2004, 22(2), 112–117.

- Almeida, A. M. d., et al. Linear regression for calibration lines revisited: weighting schemes for bioanalytical methods. Journal of Chromatography B 2002, 774(2), 215–222.