Gas Chromatography (GC) remains a cornerstone in analytical chemistry, particularly for impurity profiling, solvent quantification, and process monitoring. But as industries face increasing complexity—whether it’s trace-level detection in pharmaceuticals or quality control in fuels—the need for more selective, sensitive, and flexible detectors has never been greater.

GC-LUMA embeds a next-generation vacuum ultraviolet (VUV) detector that bridges the gap between the universal simplicity of an FID, the selectivity of a mass spectrometer, and the robustness required for high-throughput laboratories. This article unpacks the core insights from a recent expert webinar that explored the technology, real-world applications, and data workflows behind the GC-LUMA system.

What makes GC-LUMA unique?

The GC-LUMA detector operates in the vacuum ultraviolet (VUV) region of the electromagnetic spectrum, where virtually all organic compounds absorb light. This gives LUMA its defining feature: universal detection, with high absorption sensitivity and the ability to differentiate compounds based on their spectral fingerprints.

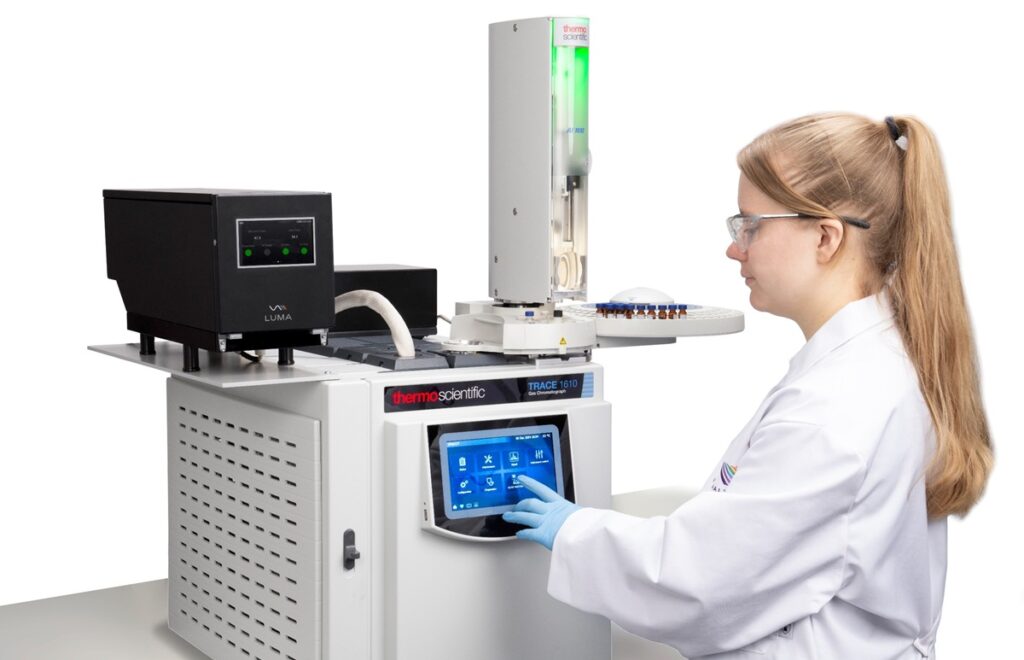

Thermo Scientific TRACE 1610 GC equipped with LUMA detector (VUV Analytics Inc.)

Unlike traditional VUV detectors that rely on CCD sensors, LUMA uses a 12-channel photodiode array. Each channel corresponds to a specific wavelength band (from ~118 to 240 nm), offering low-ppb sensitivity. It supports stable, linear quantification via Beer’s Law and provides spectral selectivity that enables analysts to distinguish between structurally similar compounds, such as isomers. Another practical advantage is that the LUMA detector does not require a vacuum pump, simplifying the system’s footprint and maintenance requirements. As a result, GC-LUMA allows users to extract both quantitative and qualitative information in a single run, making it a powerful and versatile tool.

GC-LUMA in practice: pharmaceutical applications

Dr. Sam Whitmarsh of CatSci Ltd. presented several practical case studies from pharmaceutical process development, where GC-LUMA proved especially valuable. In early-stage synthesis projects, such as those involving valsartan routes, GC-LUMA was used for detailed impurity profiling. The detector’s capability to combine impurity, solvent, and water analysis into a single method proved especially useful, particularly when working with compounds that are not easily detected by FID, such as hydroxylamine or water.

One compelling use case involved the deconvolution of co-eluting solvents. In scenarios mimicking worst-case chromatographic conditions, LUMA successfully resolved overlapping peaks by identifying differences in their absorbance at specific VUV wavelengths. This ability significantly reduces the need for extensive method re-optimization and enables faster turnaround in process development.

“LUMA gives us the selectivity of a GC-MS, but with the ease-of-use of an FID. In some cases, it’s even an order of magnitude more sensitive than FID for low-carbon or polar compounds.” – S. Whitmarsh

Water by GC: a new frontier

Traditionally, water analysis by GC presents challenges. FID cannot detect water, and manual methods like Karl Fischer titration are time-consuming and prone to variability. GC-LUMA changes this dynamic by enabling water detection as part of the routine chromatographic workflow. The detector quantifies water across a wide concentration range, from parts per million (ppm) to percent levels, and demonstrates broad linearity, for example, from 20 ppm to 2%.

Using internal standards such as tetrahydrofuran (THF), GC-LUMA enhances reproducibility while allowing simultaneous analysis of water, solvents, and impurities. This capability is particularly relevant in oligonucleotide manufacturing and other pharmaceutical contexts where precise control of residual moisture and solvent levels is critical.

Smarter data with Chromeleon CDS

As explained by Rafael Acosta, Product Manager at VUV Analytics Inc., the integration of GC-LUMA with Thermo Scientific Chromeleon CDS provides a seamless data environment that enhances usability and reproducibility. With native driver integration for TRACE 1610 GC and CDS, analysts benefit from a streamlined three-step setup process that includes wavelength range selection, acquisition frequency, and channel configuration.

Chromeleon CDS further extends the power of LUMA through automatic peak purity scoring and spectral match evaluation. Users can create and manage compound libraries from reference standards and visually confirm co-elutions or potential interferences by overlaying spectral data. In one example, positional xylene isomers, which typically co-elute chromatographically, were clearly differentiated using their VUV absorbance spectra. This integration not only improves confidence in qualitative identification but also aligns with the data integrity needs of regulated environments.

“Chromeleon’s intuitive approach to data analysis provides a way to visualize LUMA spectra data, obtain library matching capabilities and peak purity information, which makes your method development more robust and less questionable in terms of potential coelutions.” – R. Acosta

All-in-one methods: a new QC paradigm

Perhaps the most compelling outcome of GC-LUMA’s flexibility is its potential to consolidate multiple quality control tests into a single analytical method. A case study involving paracetamol illustrated how GC-LUMA could be used for identity confirmation via spectral fingerprinting, assay and impurity quantification, Class 2 residual solvent detection (such as methanol and pyridine), and water determination—all within one injection.

For QA/QC laboratories, this represents a paradigm shift. By reducing the number of instruments and analytical methods required, labs can achieve greater efficiency, consistency, and throughput. It also simplifies training, documentation, and regulatory compliance.

“When you start to think about application in a manufacturing environment, this could be really advantageous that you’re really coalescing quite a large number of tests into one run. And that could be very effective in terms of cost and speed to release some materials and the number of pieces of equipment that you’d need to have up and running to do that” – S. Whitmarsh

Filling the analytical gaps

GC-LUMA doesn’t aim to replace FID or MS. Rather, it complements them by occupying a unique space in the GC detector landscape. It offers the universality of a TCD, the selectivity of an MS, and the ease of use of an FID—but with enhanced sensitivity and spectral capability. Ideal for routine labs, process development teams, and regulated QC environments, GC-LUMA delivers more than just data: it delivers clarity, confidence, and actionable insight.

With its spectral power, method simplicity, and seamless data integration, GC-LUMA provides a compelling new option for analysts seeking to elevate their GC workflows and make better-informed decisions based on richer, more reliable information.

Want to learn more? Watch the full webinar available on-demand Shedding Light on GC‑LUMA: Revolutionizing Trace Level Impurities Detection, or explore technical resources at VUV Detector for TRACE 1600 Series GC

Visit us on LinkedIn: #TRACE1610 #ImpurityAnalysis #GCInnovation #PharmaQAQC