Wine is enjoyed by millions around the world, with a consumer following that appreciates its great variety, color, bouquet and flavor. Connoisseurs differentiate wines according to grape variety, geographical origin and year of production.

Wine is a complex mixture of hundreds of compounds, each present in a variety of concentrations. Principally, it is a blend of water, sugar, organic acids, various ions and, of course, ethanol. However, there are many more interesting compounds present, such as glycerol, aliphatic and aromatic alcohols, proteins and the polyphenol group of compounds that include color pigments, aroma and flavor molecules and tannins. Yeasts also contribute their metabolites during vinification, and carbon dioxide is used to produce sparkling wines.

Wine is a complex mixture of hundreds of compounds, each present in a variety of concentrations. Principally, it is a blend of water, sugar, organic acids, various ions and, of course, ethanol. However, there are many more interesting compounds present, such as glycerol, aliphatic and aromatic alcohols, proteins and the polyphenol group of compounds that include color pigments, aroma and flavor molecules and tannins. Yeasts also contribute their metabolites during vinification, and carbon dioxide is used to produce sparkling wines.

There are a number of issues a wine producer faces before the product sits on retailers’ shelves. They are ultimately responsible for ensuring the end product not only meets their consumers’ discerning palette, it must also be safe to drink. All raw materials used need to be of the highest quality and consistent from one batch to the next. Raw material contamination, from pesticides to heavy metals, must be checked before fermentation, otherwise serious taste and quality issues occur during shelf life. Knowing when to end the fermentation process is crucial to avoid acetification – the process that leads to a vinegar taste. Finally, another consideration is labeling requirements indicating the presence of sulfites in the final product.

Thermo Scientific has analytical and chromatography systems that offer unique testing benefits throughout the wine production process. Using these systems and techniques, coupled to our highly sensitive and selective detectors, state-of-the-art column technologies, along with the proven analytical methods presented here will help you to:

- Reduce analysis time without compromising on resolution, retention or reproducibility

- Monitor quality parameters during and after fermentation to determine flavor and stability

- Satisfy wine regulations and authentication, and labeling requirements

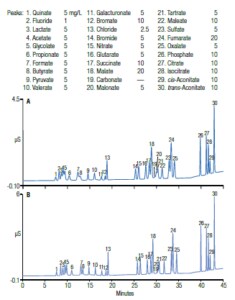

Organic acid analysis by high-pressure IC

The determination of organic acids in juices and wines was demonstrated using an ion chromatography (IC) Thermo Scientific™ Dionex™ ICS-5000+ system. The efficient separation was achieved on a Dionex™ IonPac™ AS11-HC-4μm column set, a high-resolution, high-capacity anion-exchange product designed to resolve a large number of organic acids and inorganic anions using hydroxide gradient elution. The Dionex™ EGC 500 potassium hydroxide (KOH) eluent generator cartridge-produced high-purity KOH, which ensured the excellent reproducibility of the method. A solvent gradient of 8–11% methanol (CH3OH) was added to the KOH eluent to improve the resolution of a few close-eluting peaks. The separated analytes were detected using suppressed conductivity detection.

The determination of organic acids in juices and wines was demonstrated using an ion chromatography (IC) Thermo Scientific™ Dionex™ ICS-5000+ system. The efficient separation was achieved on a Dionex™ IonPac™ AS11-HC-4μm column set, a high-resolution, high-capacity anion-exchange product designed to resolve a large number of organic acids and inorganic anions using hydroxide gradient elution. The Dionex™ EGC 500 potassium hydroxide (KOH) eluent generator cartridge-produced high-purity KOH, which ensured the excellent reproducibility of the method. A solvent gradient of 8–11% methanol (CH3OH) was added to the KOH eluent to improve the resolution of a few close-eluting peaks. The separated analytes were detected using suppressed conductivity detection.

Enzymatic analysis of glycerol in wine by photometric discrete photometry

On LinkedIn? Visit our LinkedIn page #WineAnalysis #IonChromatography