Do you really know what is in your vaccine?

Liquid chromatography is ideal for analyzing and assessing the stability of complex mixtures like vaccine formulations made from a diverse pool of ingredients.

As with any pharmaceutical, robust analytical methods to characterize the quality and stability of vaccine formulas are critical to patient safety and approval by regulatory bodies.

As with any pharmaceutical, robust analytical methods to characterize the quality and stability of vaccine formulas are critical to patient safety and approval by regulatory bodies.

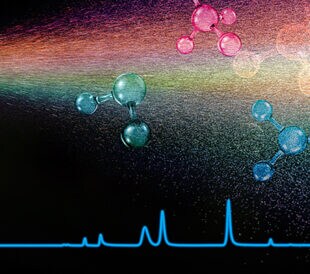

While conventional analytical HPLC-UV or LC-MS methods are a standard part of vaccine development, these techniques fall short when the supporting additives lack a chromophore or may not form gas-phase ions.

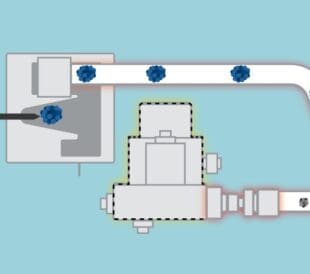

For situations where analytes in a sample are incompatible with UV and MS detectors, scientists turn to an advanced LC detection approach called charged aerosol detection to get an in-depth look at both the composition and stability of vaccines.

In this blog, we explore why the Thermo Scientific™ Vanquish™Charged Aerosol Detector or the Thermo Scientific™ Dionex™ Corona™Veo™ …is a must-have for every vaccine developer.

Standard vaccine ingredients

A variety of vaccine formulas are out there, but not all are as complicated as you might think. Vaccines consist of the antigen plus a mixture of inert components called excipients, like stabilizers, preservatives, buffers, adjuvants and small amounts of process residuals.

The antigen in a vaccine is the component responsible for eliciting an immune response. Several types of antigen are found in vaccines. Traditionally, these are live attenuated, killed whole organism, or toxoids.

Newer antigens are also built of subunits of the pathogen, like purified or recombinant-produced polysaccharides, peptides or proteins. Other antigens are pathogen presenting virus-like particles while more recent vaccines are viral vectored and non-viral vector nucleic acid vaccines.

Thanks to advancements in molecular biology and lipid nanoparticle delivery technology, the new class of mRNA vaccines from Pfizer-BioNTech and Moderna were recently approved to fight the battle against COVID-19.

The role of excipients in vaccines

Although there is a lot of focus on the active pharmaceutical ingredient, there is more to a vaccine than the antigen alone; the role of excipients in a vaccine must not be overlooked.

Excipients encompass a broad class of inert components designed to protect the active ingredient from denaturation during manufacturing, storage and delivery, and promote vaccine effectiveness. Without the addition of excipients, vaccines could lose efficacy, stability, and safety aspects.

Common classes of excipients and the roles in vaccines are:

-

- Adjuvants — help promote the effectiveness of a vaccine by reducing the dose amount or duration, extending the immune system memory, or regulating cell response

-

- Antioxidants — thwart oxidative damage of the active ingredient

-

- Buffers —keep the pH balance right

-

- Preservatives — inhibit microbial contamination of the formulation

-

- Surfactants — aidstabilization, solubility, and prevent adsorption

-

- Tonicity agents — added to injectable preparations to prevent osmotic shock at the site of injection and reduce local irritation

-

- Lipids — protect mRNA and facilitate its delivery to cells

Shortcomings of HPLC-UV methods in excipient analysis

When developing an LC method to test the quality of the individual vaccine ingredients and the final formulation, you need an approach capable of measuring the discrete components.

Given the broad chemical nature and importance of excipients in maintaining antigen viability, the LC methods used to characterize a vaccine must include the entire formula and consider the chemical structure of each additive.

Most excipients lack double bonds and aromatic rings in the chemical structure, rendering traditional HPLC-UV methods insufficient for quantifying the excipient, or determining product quality — like tracking lot-to-lot variability during manufacture or monitoring the levels of impurities and degradation products.

If your LC method cannot detect or see every chemical, impurity, or degradation product in a vaccine, this puts your ability to get federal approval at risk and, even worse, poses a potential danger to patients.

Why CAD is better suited for vaccine excipient analysis

One way to minimize risk and ensure vaccine safety and efficacy is to use charged aerosol detection. This method of detection is ideal for analytes without any chromophores and provides a solution to the analytical incompatibly of HPLC-UV methods with respect to excipient analysis.

The best part is you do not have to choose one detection over another. You can use CAD to complement your HPLC-UV analysis in a situation where excipients in a formula are a mix of UV active and inactive components. Using these tools together gives you a robust and reliable analytical detection method to determine the stability of all vaccine excipients.

The CAD is a universal detector able to detect all non-volatile, and many semi-volatile analytes in a sample. This uniform response enables the accurate quantitation of most excipient in a vaccine formulation.

The major benefits of using CAD to analyze vaccine excipients are:

-

- Sensitive detection independent of whether a chromophore is present or not (unlike UV) or whether the compound forms gas-phase ions (unlike MS).

-

- Uniform response, as in the ability to obtain the same response for all components regardless of the analyte structure.

-

- Standard-free quantitation. You don’t need a standard to quantify an unknown. This is important when reference standards are unavailable for impurities and degradants.

Ensure vaccine efficacy with Thermo Scientific charged aerosol detectors

Charged aerosol detection is a must-have analytical tool critical to the development process and monitoring quality control in large-scale manufacturing. This cutting-edge technology enables the in-depth characterization of vaccine composition, stability, and identification of impurities and degradation products.

Collecting robust and reliable stability data requires full visibility of each vaccine component is paramount to overcoming federal hurdles. Having a deeper understanding about how an excipient degrades over time allows you to fine-tune the formula to deliver stable and effective vaccines.

The last thing you want to happen in your business is to spend millions of dollars on vaccine development, only to be denied market approval due to poor product viability.

Now that you have the knowledge and access to the right tools, are you ready to develop the best vaccines on the market? Simply build your Vanquish LC-CAD system and request a quote in minutes using our online configurator tool here.

Need more information about our analytical LC systems and detectors? Take an online tour of our Vanquish Core HPLC and Vanquish Horizon UHPLC systems here.

Additional References

Thermo Scientific CAD resources:

-

- CAD bibliography highlighting peer-reviewed literature publications from 2005-2021.

-

- Charged aerosol detection – factors affecting uniform analyte response.

-

- Getting the most out of your charged aerosol detector: Factors influencing charged aerosol detector performance.

-

- https://assets. BioNTech thermofisher.com/TFS-Assets/CMD/brochures/eb-73172-hplc-cad-excipients-eb73172-en.pdf

-

- Getting the most out of your charged aerosol detector: Factors influencing charged aerosol detector performance.

-

- HPLC-CAD Surfactants and Emulsifiers Applications

-

- Polysorbate 80 profiling by HPLC with mass and charged aerosol detection.

Literature Resources

-

- Functionalized lipid nanoparticles for subcutaneous administration of mRNA to achieve systemic exposures of a therapeutic protein.

-

- Analytical profiling and stability evaluation of liposomal drug delivery systems: A rapid UHPLC-CAD-based approach for phospholipids in research and quality control.

-

- A Thermostable, Flexible RNA Vaccine Delivery Platform for Pandemic Response.

-

- Development of a formulation platform for a spray-dried, inhalable tuberculosis vaccine candidate.

-

- Squalene Emulsion Manufacturing Process Scale-Up for Enhanced Global Pandemic Response.

COVID Vaccine Resources

-

- There are four types of COVID vaccines: here’s how they work:

Episode 4: Introducing a More Confident Era in HPLC-CAD Analysis

The first Charged Aerosol Detector (launched in 2005) set ne...

Read More

Episode 3: Understanding How Charged Aerosol Detection (CAD) Works

Welcome back to our series on Charged Aerosol Detection (CAD...

Read More

Episode 2: The Benefits of CAD Compared to Other Universal Detectors: ELSD and MALS

Welcome back to our series on Charged Aerosol Detection (CAD...

Read More

Episode 1: The Benefits of Charged Aerosol Detection (CAD) in High-Performance Liquid Chromatography (HPLC)

High-Performance Liquid Chromatography (HPLC) is a cornersto...

Read More