From January 2026, Electric Vehicle (EV) and industrial batteries in the EU will have to comply with the EU Battery Regulation Amendment¹.

It is soon becoming unavoidable for the industry—and batteries with a capacity of over 2 kWh—not only to continue to navigate regulations², but also to demonstrate compliance and track and trace materiality through production and product output.

Regardless of the origin of the battery, a digital ‘passport’ will be required for the battery to be listed in the European market. The regulation is in place with the express aim of protecting the environment, ensuring a reduction in the amount of hazardous waste found in batteries, helping consumers to be better informed, and driving circular and sustainable growth in the industry.

But its arrival lands responsibility directly on the shoulders of the party placing the battery on the market, to ensure that all required data is entered in the digital record and this information is correct and up to date. And for each battery on the market to proclaim its own transparent story, input from players right across the entire value chain will be critical.

“But with the arrival of the Battery Passport and new Regulation, what does it mean for battery manufacturers to comply, and how can manufacturers warrant the quality and true origin of materiality?”

What is a Battery Passport?

The Battery Passport serves as a system of tracking and providing relevant information about the battery’s history, manufacturing details, performance metrics, maintenance records, and any relevant certifications. Its development is grounded in the Global Battery Alliance Guiding Principles to step the industry, (its stakeholders, government institutions, NGOs, auditors and the public), towards a sustainable value chain, helping to make sure batteries live up to their true potential. So, for example, for potential customers of EV cars (and subsequent owners), labels and a QR code on the Battery Passport will give access to crucial information about the battery’s condition, capacity, and usage patterns. This gives end users access to information about the battery’s health, estimated remaining lifespan, and helps consumers make informed decisions about whether to repurchase or replace.

Battery Pass consortium, of which Thermo Fisher Scientific is a member, describes the purpose of the Battery Passport as enabling “the shift to a circular economy and creating a level playing field.” This raison d’être is therefore not only about enhancing transparency, but also traceability, and trust within the EV market.

Why is it needed?

The Battery Passport helps to align power and transport industries with the goals of the Paris Agreement on climate change by 2030. According to a GBA report and research, moving the battery industry towards a circular value chain can enable the 30% reduction in power and transport sector emissions required to stay on track to meet the 2°C goal of the Paris Agreement – as governments will increasingly rely on electrification and batteries to help meet these goals. But it also offers other opportunity for change…

Lauren Pagel, Policy Director at Earthworks, advocates the human impact of the industry, supporting the new Passport and specifically the Battery Amendment regulation as it brings an opportunity “to break away from irresponsible mining, what has disproportionately impacted front lines and Indigenous communities and the Global South and marginalized communities³.”

Battery Passports will also facilitate the second-life use of EV batteries. After the battery is no longer suitable for EV applications, it can still have useful capacity for other purposes, such as energy storage systems. The Passport therefore intends to provide all the essential information to enable proper repurposing and ensure optimal utilization of the battery’s remaining potential.

Circling around transparency

Barbara Metz, Executive Director at Deutsche Umwelthilfe describes these as overdue regulations and is calling for “the Commission to exploit the circular economy potential for recycling batteries and their raw materials as quickly as possible through supplementary legal acts4.”

Moving the battery industry to a circular value chain economy invariably means Battery Passports will require more input from stakeholders right across the value chain—including miners, refiners, active material producers, cell producers, module producers, battery producers, automotive OEM’s as well as battery services, refurbishing and repurposing companies—where each will have an indispensable role to play in helping a battery tell its own transparent story.

“Quality means doing it right when no one is looking.” – Henry Ford.

Battery technology is evolving, (for example, salt and sand could replace lithium) and different battery chemistries will have varying combinations of desirable attributes, but in general, several common qualities constitute a good EV battery: the battery’s power density and how quickly it can deliver energy, how fast it can charge, its longevity and ability to resist degradation through the lifespan of charge and discharge cycles, the safety of the battery, the cost, the environmental impact, recycling and repurposing (including reducing the use of rare or environmentally sensitive materials). Other factors include the battery’s compatibility and scalability with EV platforms and its ability to seamlessly integrate with EV design configurations.

But there are also manufacturing and supply chain considerations: an ideal EV battery of quality should be feasible to manufacture at scale, ensuring a reliable supply chain and efficient production processes. Factors like material availability, ease of assembly, and manufacturing costs all contribute to the viability of the battery in mass production.

The material quality of the battery, increasingly plays a fundamental role in the transparency of the battery as a product, and its own Passport, for several reasons:

- the quality of battery materials directly impacts the performance and efficiency of the battery. High-quality materials result in improved overall performance of the battery.

- high-quality materials better meet stringent safety standards, enabling manufacturers to ensure the reliability and durability of their battery product, instilling the confidence that The Battery Passport will bring to end-users, and minimizing the chances of malfunctions or accidents.

- using high-quality materials help manufacturers maintain tighter control over production variables, resulting in more consistent battery performance – vital for meeting customer expectations and ensuring compatibility within larger battery systems.

- high-quality materials also contribute to more sustainable battery manufacturing practices, e.g., materials with higher energy density can enable the production of batteries with a smaller environmental footprint since fewer resources are required to achieve the desired energy storage capacity. And finally,

- high-quality materials provide a foundation for innovation, allowing researchers and manufacturers to explore new chemistries, designs, and manufacturing techniques with confidence.

Proving authenticity

But with the arrival of the Battery Passport and new Regulation, and knowing that material quality is central, what does it mean for battery manufacturers to comply and how can manufacturers warrant the true quality and origin of materiality? In other words, how can the industry prove the trace elements used in the battery production, right across the value chain, are in fact as described, and of the true quality claimed in the Battery Passport?

Setting-standards and the seal of quality with sophistication

What is clear, is that by using high-quality materials, manufacturers can not only produce batteries that meet or exceed the requirements of various applications, but also track and help ensure the traceability of materials that may be listed on the Battery Passport, while also driving advancements in the field of energy storage.

What is yet not so clear to operators within an industry where battery material quality, assurance of quality and traceability increasingly matter (and where there is otherwise a reliance on traditional manufacturing systems), is that erudite manufacturing QA/QC and R&D laboratory informatics solutions provide the missing piece of the puzzle. They enable the efficient 360-degree laboratory, data and procedural workflow management that is needed to guarantee the regulatory compliance and provide the complete traceability advantage for the incoming Battery Passport.

A LIMS helps to stamp The Battery Passport with authenticity

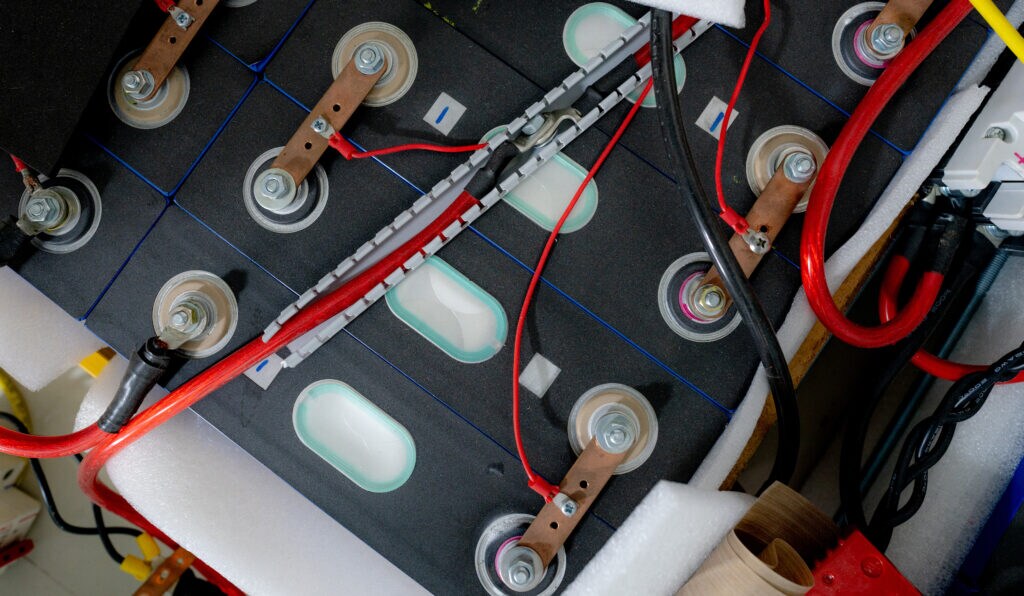

To ensure the quality of raw and in-process materials for The Passport, manufacturers need to employ a variety of analysis tests to certify the battery’s quality and safety and there is a range of tools and instruments to support this. X-ray diffraction, scanning electron microscopy, and wet-chemistry approaches are all used in battery manufacturing workflows to ensure the quality of raw materials and in-process materials. Aside from these pre-production and in-process testing workflows, end-product performance testing is also required to ensure quality and safety. For an efficient, compliant production line, large amounts of information including test results, instrument metadata, calibration data, and other data is generated, which can be substantial, and that must be properly documented and made available to the appropriate teams, customers, and stakeholders.

A sophisticated control strategy is needed to aggregate the vast quantities of data associated with battery quality management. Organizing and retrieving this data must be possible with informatics systems that can handle it securely. Above all, it must be able to maintain the integrity of testing data to ensure decisions on the batch release are taken based on reliable insight.

A laboratory information management system (LIMS), such as Thermo Scientific™ SampleManager™ LIMS software, differs from an MES for several reasons, but it also simplifies data management and information retrieval to support fast, insight-driven decision-making, connects with other enterprise systems including manufacturing execution systems, instruments and equipment, supports testing, centralizes data management, and is fast becoming the essential tool to meet the stamp of approval of The Passport and to help give an identity to the EV industry’s most important component.

What you manage you can improve

Key to a LIMS functionality is its ability to support the data that is required to be passed at each point in the battery’s manufacturing process, wherever the LIMS is used, and report insights about the battery’s preproduction, in-process and post process performance and condition.

Features in SampleManager LIMS, such as out-of-the-box dashboards are vital to display key laboratory and business insights throughout the process. Its Statistical Quality Control module, for example, charts how process data is trending in real time, and when battery results fall outside specific limits, the LIMS can automatically alert a process or operations manager during the battery testing. The Laboratory Execution System in the software facilitate battery cycle testing and failure analysis, digitally stepping users through the cycle testing process, capturing critical data as the test is performed, then graphing the captured data, to illustrate how battery’s performance may have changed over time. This data is easily formatted and exported for reporting.

Across the breadth of the battery value chain—be that characterization and failure analysis, bulk process quality control by design and material rejections, process control and in-line inspection, failure analysis and rejection, and inspection and characterization of the battery for reuse—a LIMS is fast becoming critical to support regulatory compliance and automate workflows.

A LIMS provides the traceability of materiality, from research to quality product output, and to recycling process management, and helps to assure that through the Battery Passport, the battery industry’s growth is circular, sustainable, low carbon, dedicated to reducing waste of all the batteries we will need in the future.

Learn more here.

References:

- EU battery passport regulation requirements (circularise.com)

- The regulations governing the manufacture of electric vehicle (EV) batteries vary by country but common regulations and standards that apply to EV battery manufacturing include Safety Regulations: Battery manufacturing is subject to safety regulations to ensure the safe handling and storage of hazardous materials, such as lithium-ion cells and electrolytes. These regulations often cover aspects such as fire safety, chemical handling, and worker safety. Environmental Regulations: Battery manufacturing processes can have environmental impacts, particularly in terms of waste management and the use of hazardous materials. Regulations aim to mitigate these impacts through measures such as waste disposal guidelines, recycling requirements, and restrictions on the use of certain chemicals. Quality Standards: There are various quality standards that battery manufacturers may need to comply with, such as ISO 9001 (Quality Management Systems) and ISO 14001 (Environmental Management Systems). These standards ensure that manufacturing processes are consistent, efficient, and environmentally responsible. Performance and Testing Standards: Battery performance and safety testing standards are essential to ensure that EV batteries meet minimum quality and safety requirements. For example, standards like IEC 62660 and UN 38.3 address battery performance, reliability, and safety considerations. Transportation Regulations: Batteries used in electric vehicles are subject to transportation regulations, especially during shipping or distribution. These regulations cover aspects like packaging, labelling, and handling procedures to ensure safe transportation of batteries.

- PowerPoint Presentation (thebatterypass.eu)

- EU Battery Regulation – ECOS and Deutsche Umwelthilfe welcome deal, call for improvements in raw materials extraction and battery life – ECOS (ecostandard.org)

Leave a Reply