Introduction

In the development of solid-state batteries, advanced characterization techniques are essential for understanding the materials involved. These techniques offer detailed insights into the structure and properties of battery components, paving the way for more efficient and safer energy storage solutions. This part of the series explores several cutting-edge characterization methods that are revolutionizing solid-state battery research.

Electron Microscopy

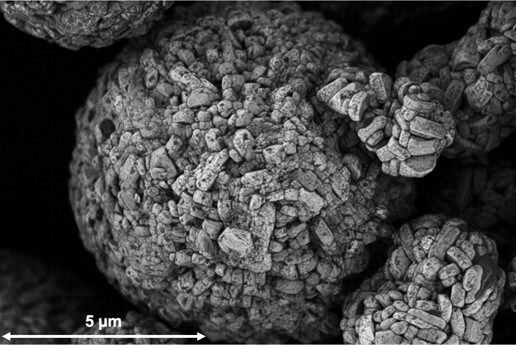

1. Scanning Electron Microscopy (SEM): SEM is a powerful tool for examining the surface morphology and structural details of battery materials at the micron scale. By bombarding a sample with electrons and measuring the emitted secondary or backscattered electrons, SEM produces high-resolution images that reveal the texture and composition of the surface. One example of how researchers are using SEM to characterize materials used in next generation battery development is to observe and characterize thin coatings used on cathode active material. (In Figure 1 below, Thermo Scientific’s Apreo ChemiSEM™ was used to example an ultra-thin coating on NMC cathode particles using an extremely low landing voltage.)

Figure 1: 600 eV backscattered electron image (BSE) of NMC cathode particle.

- ChemiSEM Technology: This innovative approach enhances traditional SEM for solid-state battery research by providing a faster, more accurate and streamlined approach to EDS, using live color imaging that highlights chemical elements. ChemiSEM allows researchers to quickly identify and differentiate between various materials within a sample, offering immediate insights into material composition without the need for additional analytical techniques. This is due to ChemiSEM being fully integrated into the SEM and always on.

To learn more on SEM technology for battery science

2. DualBeam Focused Ion Beam (FIB)-SEM Systems:

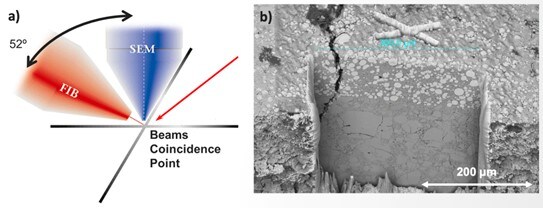

- FIB systems are integrated with SEM to create DualBeam systems that enable both imaging and material manipulation. These systems are particularly useful for fast, site specific cross-section sample preparation, 3D material characterization, and S/TEM lamellae preparation allowing researchers to study the internal structure of battery components. Figure 2, below, shows how cross-sections are prepared in the DualBeam and a representative sample of a solid-state battery cathode after cross-section preparation. Using the SEM, one can easily observe the internal structure of the sample, make measurements of layers and particles, and perform analytical characterization as required.

Figure 2: 2a – schematic of sample relative to the FIB and SEM in a DualBeam, 2b – Cross-section of solid-state battery cathode prepared with PFIB.

- Plasma FIB: Primarily, plasma FIB uses inert noble gas species like xenon or argon to examine larger volumes of material, making it ideal for studying bulk properties and large-scale features within the battery. An additional benefit of an inert gas species as a primary ion source is that there are minimal ion/sample interactions with lithium containing materials.

- Gallium FIB: Gallium FIB is used for detailed analysis at smaller scales, providing high-resolution imaging of fine structures and interfaces, however, using a gallium FIB can cause subtle changes in lithium containing structures because of strong interaction with gallium and lithium at room temperature.

To learn more on DualBeam technology for battery science

3. Transmission Electron Microscopy (TEM):

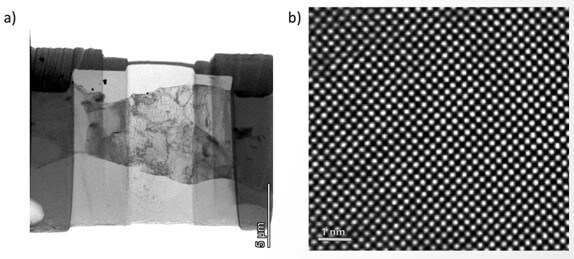

- TEM provides high-resolution characterization at the sub-nanometer scale, delivering information to support the elucidation of behavior at the atomic level. Using TEM, scientists and engineers can delve deeper into the intricate details of material structures such as atomic arrangement and crystal structure to gain insights into the relationship between structure and functionality that are inaccessible with alternative techniques.

- For battery applications, TEM techniques such as high-resolution imaging, electron diffraction, EDS, and EELS, can provide valuable insights into the morphology, crystal structure, and chemical information of battery components. It is well-suited for nanoscale characterization of beam-sensitive materials commonly found in battery research, such as solid-electrolyte interphases (SEI). Resolving the SEI’s composition and structure is essential for understanding how lithium ions move in and out of the electrode, providing information on how the capacity retention drops over battery cycling. Such insights are crucial for developing next-gen batteries and gaining a mechanistic understanding of aging and failure mechanisms. Figure 3, below, shows how TEM is used to investigate a lithium metal sample.

Figure 3: 3a – low magnification image of Li-metal at 200 keV with the HAADF detector, 3b – HR-TEM image of lithium lattice structure.

Watch our webinar discussing SEI characterization via TEM

X-ray Photoelectron Spectroscopy (XPS)

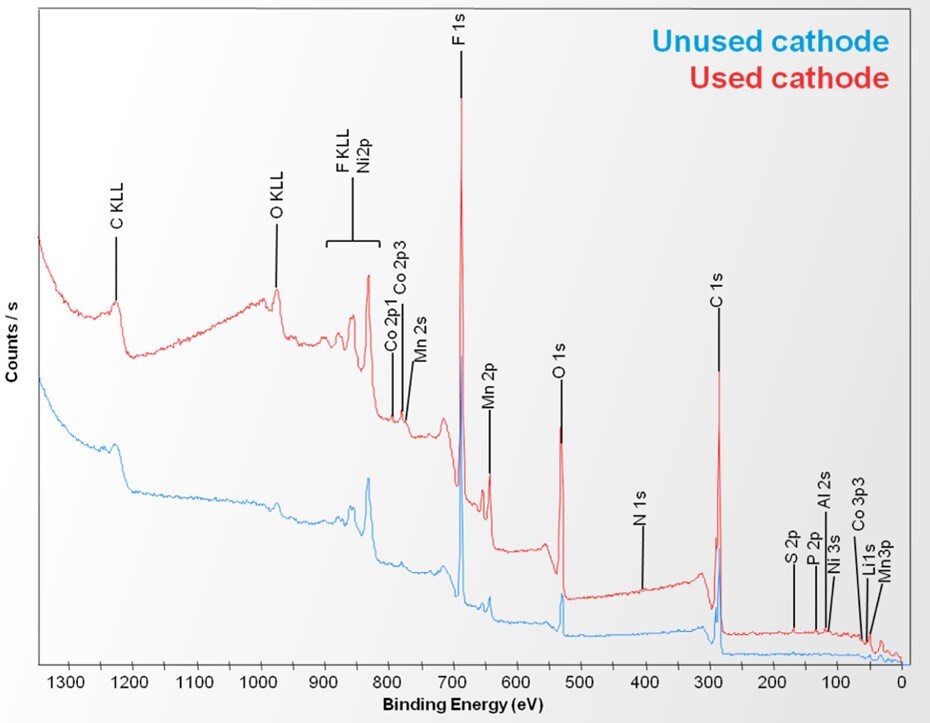

X-ray photoelectron spectroscopy (XPS) is a surface analysis technique that provides quantitative elemental, electronic state, chemical state, and bonding information for the uppermost layers of a sample. For the battery industry, it is especially useful for studying surface phenomena, such as interface reactions, surface contamination, and notably, for elucidating the mechanisms associated with the formation of the SEI. For example, cathode and anode materials of Li-ion cells can be studied to confirm post-cycling changes in composition, to understand the changes in the chemistry of the electrode components, and to determine how the solid electrolyte interface (SEI) layer varies in depth as it develops. XPS has proved useful in studying surface pre-treatment of graphite electrode materials to significantly slow the irreversible consumption of material during battery charging. Figure 4, below, shows how XPS can be used to show chemical changes in cycled and pristine cathode active material.

Figure 4: Survey spectra from pristine cathode (blue) and cycled cathode (red) samples.

To learn more on XPS technology for battery science

Image Analysis Software

1. Turning Raw Data into Insights:

- Advanced imaging techniques produce vast amounts of data that must be analyzed to extract meaningful insights. Image analysis software is used to process and interpret this data, providing quantitative measurements and visualizations that enhance understanding of material properties.

- 3D Imaging: Some software (like Avizo) supports both 2D and 3D imaging, offering a comprehensive view of the material’s structure. This capability is crucial for assessing the quality of battery manufacturing processes, investigating aging, and understanding the connectivity and tortuosity of electrode materials.

2. Quantitative Analysis:

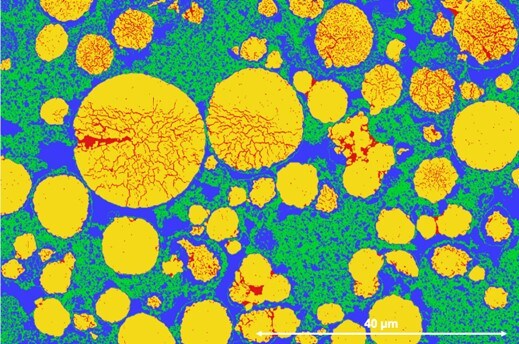

- Some software, (example: Avizo Trueput™) allows researchers to identify and measure complex features in electrode materials and entire cells. By quantifying aspects such as pore size, distribution, and connectivity, researchers can correlate structural characteristics with performance metrics, guiding improvements in battery design.

Figure 5: Example of NMC cathode cross-section segmented for particle cracking by Avizo Trueput.

3. Predictive Modeling:

- In addition to image analysis, some software can be used for predictive modeling. By simulating the behavior of materials under various conditions, researchers can predict how changes in structure or composition will impact battery performance. This capability is invaluable for optimizing materials and accelerating the development of next-generation batteries.

To learn more on Avizo solutions for battery science

Conclusion and Notes

Advanced characterization techniques are revolutionizing solid-state battery research, providing detailed insights into the materials and their interactions within the battery. Techniques like SEM, TEM, FIB, and XPS, combined with sophisticated image analysis software, enable researchers to optimize battery materials for enhanced performance and safety.

Join our battery community to learn more and stay current with the latest Thermo Scientific battery solutions and technologies.

A special thanks to Dr. Chengge Jiao, Dr. Eric Goergen, Dr. Lin Jiang, Dr. Letian Li, Dr. Zhao Liu, Dr. Maria Meledina, Dr. Tim Nunney, Dr. Luigi Raspolini, for their contributions to this post.

Leave a Reply