Scientists across a range of disciplines, including materials science, have long been inspired by the wonders of nature. In an effort to create novel materials with enhanced mechanical properties, scientists are now designing bioinspired materials — man-made materials that mimic biological structures. The goal is to replicate the complex structures that have been refined by millions of years of evolution, in order to overcome the limited strength, ductility, and fracture resistance of traditional materials like metals and ceramics.

Scientists across a range of disciplines, including materials science, have long been inspired by the wonders of nature. In an effort to create novel materials with enhanced mechanical properties, scientists are now designing bioinspired materials — man-made materials that mimic biological structures. The goal is to replicate the complex structures that have been refined by millions of years of evolution, in order to overcome the limited strength, ductility, and fracture resistance of traditional materials like metals and ceramics.

Creating bioinspired materials

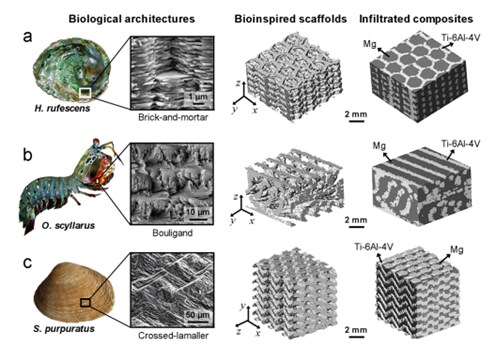

One such study, led by Mingyang Zhang and published in Nature Communications, took inspiration from three sea creatures: a sea snail, a mantis shrimp, and a clam. The researchers replicated a brick and mortar like structure from the nacre of the sea snail’s shell, a twisted wood-like structure similar to Bouligand architecture from the shrimp’s exoskeleton, and a crossed-lamellar architecture from the clam’s shell. All three of these structures show outstanding efficiency in their natural states.

The structures of the representative biological prototypes (sea snail, mantis shrimp and clam) are displayed together with the brick-and-mortar, Bouligand and crossed-lamellar architectures. Additionally, the bioinspired scaffolds and the infiltrated composites are shown. Ref: Fig. 1: Bioinspired architectures of 3-D printed Ti-6Al-4V scaffolds and their infiltrated Mg-Ti composites. | Nature Communications

To create the structures, the team chose to use 3D-printed titanium combined with a second phase of magnesium. They chose these two metals for their large difference in stiffness, which mirrors the varying stiffness found in biological materials. By using 3D printing, they were able to build the structures from the bottom up — mimicking the natural formation process. The process also allowed them to create a porous scaffold that could be infiltrated by magnesium without the need for pressure.

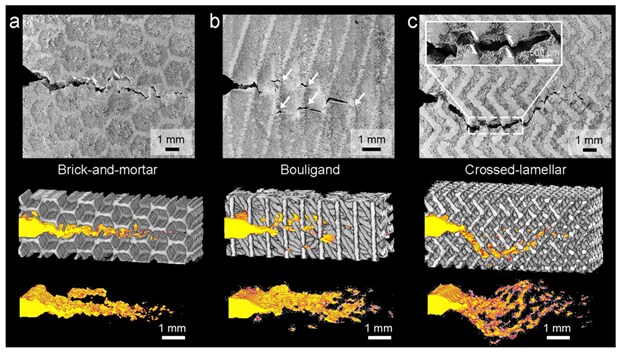

Once the materials were manufactured, the team used X-ray and electron microscopy to assess the absence of pores. They then applied tensile stress to the materials, which created fractures, and imaged the materials once again. The imaging data was processed and brought to life by Thermo Scientific Avizo Software, which provided advanced image segmentation, 3D visualization, and quantitative analysis that allowed the team to clearly see and quantify the fractures.

Fracture characterization with Avizo Software

Using the image segmentation tools in Avizo Software, the team was able to automatically identify and highlight fractures within the material. The images showed that the fractures did not move in a straight path through the material, but rather deflected and twisted.

The figure displays the Brick-and-mortar (a), Bouligand (b) and Crossed-lamellar ( c) architectures in SEM images and in CT volume rendering. White arrows indicate the cracks.

After comparing their materials to others, the team found that the bioinspired materials displayed superior in terms of strength and ductility. In particular, the crossed-lamellar architecture inspired by the clam shell emerged as the strongest of the bunch.

Ultimately, the study shows that bioinspired materials, with their enhanced strength and durability, could be a promising alternative to traditional materials in both structural and biomedical applications. It is also a clear demonstration of how advanced imaging equipment and software can combine with high-tech fabrication and testing to make scientific leaps that would otherwise be impossible.

To learn more about how Avizo Software can support and empower composite characterization, watch our introductory webinar.

Luigi Raspolini is a Product Marketing Manager at Thermo Fisher Scientific

Leave a Reply