For a comprehensive understanding of a material, usually more than just one analytical technique is required. Techniques complementing rheological measurements are e.g. GPC, thermal analysis, microscopy, and FTIR spectroscopy. By combining two analytical techniques in one instrument the amount of information gathered from one single sample is maximized.

Specifically, can you introduce dynamic rheometry and FTIR spectroscopy to be employed simultaneously to monitor structure development during the reactive processing of a polyurethane resin system? It is certainly intuitive that rheological properties of polymers depend on molecular mobility, which is influenced by molecular structure. And although both rheometry and FTIR spectroscopy can record dynamic progressions, they cannot detect interactions when used in parallel. This requires their combination in one instrument to analyze one sample at the same time under exactly the same conditions.

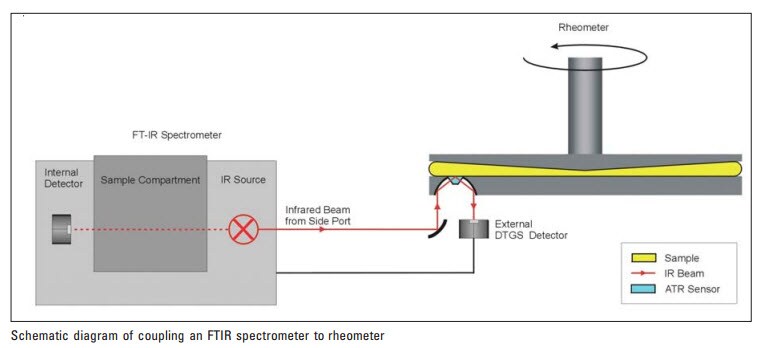

Since infrared spectroscopy is a tool capable of identifying the nature of molecular structures and transformations, the addition of an FTIR spectrometer to a rotational rheometer gives the researcher another level of detail pertaining to the comprehension of rheological applications.

With a rheometer, the steady state and time dependent viscoelastic properties of a material can be studied as a function of stress and/or strain. However the viscoelastic properties of a material depend on the structure and especially the structural changes of the material on the molecular level. Infrared spectroscopy is an excellent tool for determining the identity and quantities of molecules in a sample. If you could use a combination instrument, both physical and chemical information could be obtained on a sample at the same time using one instrument. The result enables a comparison of chemical information with rheological properties. Ensuring the instrument operates in the mid-infrared spectral range since all fundamental absorption bands of a sample are typically found between 400 – 4000 cm-1 (2.5 – 25 μm), covers the so-called fingerprint region which is generally accepted as unique for each molecule.

It is also advisable to make sure the stationary plate of the rheometer features a monolithic diamond element that serves as the ATR (attenuated total reflection) sensor, offering a single internal reflection. The diamond element offers an excellent inertness to chemical properties of materials and abrasion. Compared to standard infrared transmission spectroscopy or specular reflection spectroscopy techniques, the sample thickness can thus be adjusted to the rheological needs and is independent from the infrared spectroscopy requirements. Accordingly, any plate or cone geometry up to a diameter of 60 mm can be used for all testing methods offered by a rotational rheometer. The diamond is integrated in the center of the lower plate. A motor-driven horizontal movement of the lower plate will enable the ATR sensor to be positioned at different distances between the center and a maximum of 45 mm.

Take a look at this schematic diagram of an FTIR spectrometer coupled to a rheometer:

It is helpful if the instrument can be equipped with two different temperature control units, either with a Peltier temperature control unit (0-100 °C) or an electrical unit for temperatures from ambient up to 400 °C. Several wire grid polarizers in manual and automated versions will allow you to set the infrared radiation polarization direction both parallel and perpendicular to a fixed reference direction of the sample.

In our next article, we will give details about an experiment we conducted to obtain detailed analysis of curing reactions of polyurethane resins using technology involving simultaneous rheometry and FTIR. We found that the above-mentioned technology and instrumentation gave us the simultaneous acquisition of FTIR spectra needed to track the evolving chemical constitution in all details and thus reveal the relation between the visco-elastic properties and individual reactive groups of a complex polymer. It helped us obtain real-time conversion information for studying cross-linking reactions at which a transition from the liquid to the solid phase takes place.

In our next article we will give the details of the experiment, including method, sample preparation, spectra, and results. If you can’t wait, you can read about it in this application note: Detailed analysis of curing reactions of polyurethane resins using the Rheonaut technology for simultaneous rheometry and FTIR.

Leave a Reply