The increasing regulatory pressures to build more fuel-efficient cars, means the plastics industry is now competing with the steel industry in automotive manufacturing. As the industry utilizes lighter-weight, higher-strength steel components that provide improved fuel economy, strong but lighter quality plastics are also being looked at for automotive components. In fact, Glass Fibre-Reinforced TPU (thermoplastic polyurethane) products are becoming of increasing interest when it comes to lightening of automotive structural parts.

The increasing regulatory pressures to build more fuel-efficient cars, means the plastics industry is now competing with the steel industry in automotive manufacturing. As the industry utilizes lighter-weight, higher-strength steel components that provide improved fuel economy, strong but lighter quality plastics are also being looked at for automotive components. In fact, Glass Fibre-Reinforced TPU (thermoplastic polyurethane) products are becoming of increasing interest when it comes to lightening of automotive structural parts.

According to the American Chemistry Council, “TPU can be compounded for use in numerous applications where greater structural integrity is required, such as for automotive body side moldings. For example, when mixed with glass fiber or mineral fillers, TPU’s properties of abrasion resistance, paintability, high impact strength and good low temperature flexibility can all become enhanced, and the compound also demonstrates good fuel and oil resistance and high melt flow characteristics.”

Of course, the amount of glass fiber in the mixture will affect the integrity and quality of the product. Raw material batch variation can lead to a high reject rate, especially when injection moulding large parts or extruding on large extruders. In order to help combat against large amounts of products being rejected, we tested two Glass Fibre Reinforced TPU batches to see if we could differentiate them by determining their viscosity using an extruder capillary rheometer.

We used a torque rheometer with twin screw laboratory extruders, venting screws and rod capillary die to conduct the test. The two sample materials tested consisted of Glass fibre reinforced TPU (thermoplastic polyurethane, pre-dried).

The polymer was molten and homogenized in the extruder, transported to the die and pressed through the rod capillary. Stepwise the extruder speed was changed and the output at each speed step was measured with a balance. From the mass flow data, the melt density and the capillary geometry shear rate was calculated. At each speed step a pressure transducer measured the pressure in front of the capillary. From that data the shear stress was calculated. The quotient from the shear stress and the shear rate gave the melt viscosity.

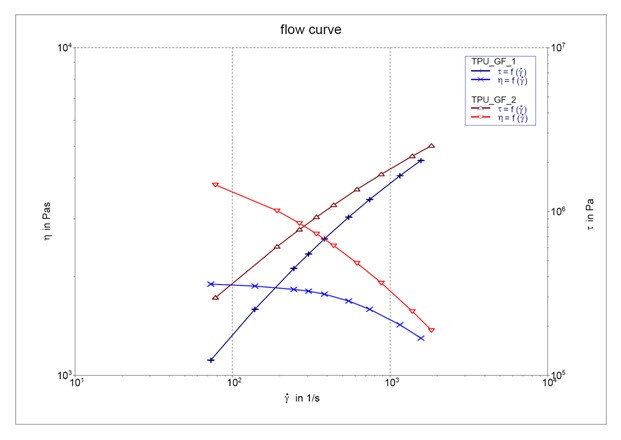

We found that Sample 2 showed a much higher viscosity than Sample 1 over the whole shear rate range. At a shear rate value γ = 200 1/s the viscosity of sample 2 was approximately 50 % higher than that of Sample 1. The shear stress and viscosity curves of both samples ran closer to one another in the high shear rate range. Therefore differentiation between these samples was better accomplished at a lower shear rate range.

From the measurements it was also seen that the viscosity of Sample 2 dropped faster with increasing shear rate. So the pseudo-plastic behaviour of Sample 2 was much more pronounced. In the shear rate range of γ = 200 – 2000 1/s, the viscosity of Sample 2 dropped twice as markedly as Sample 1.

The test showed that the ability to analyze the flow characteristics of a polymer compound under conditions which approximate to actual processing helps enable manufacturers to avoid producing products that do not meet specifications.

To read more details about this study, including instruments used, test conditions and temperatures, and diagram of test results of the two samples superimposed in one graph, download the Testing the Flow Characteristics of Glass Fibre Reinforced TPU application note.

Leave a Reply