Our last article addressed carbon nanotubes (CNTs) — which are graphite sheets rolled into seamless tubes just a few nanometers in diameter and up to several millimeters in length — and their use in industry.

Because the CNT particles are potentially hazardous to health, the safe handling and avoidance of CNT dust is important.One approach addressing the safe handling and avoidance of CNT dust is to have the CNTs pre-dispersed in a suspension.

We conducted an experiment to see if a lab scale twin screw compounder can be used to prepare compounds from polymers and CNTs using CNT suspensions. Here is a summary of the experiment. Details can be found in the link at the bottom of the page.

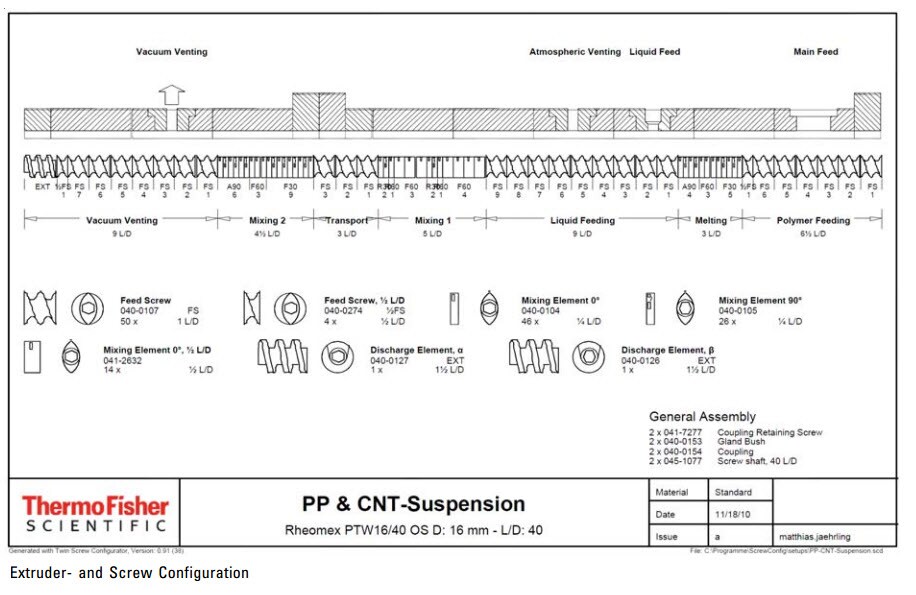

Our test material included a base polymer [Polypropylene Metocene HM562S (LyondellBassell)] and two CNT-Ethanol suspensions with different functionalization (Rescoll/France). We used a torque rheometer system with a co-rotating twin screw extruder, a gravimetric roto tube feeder for pellets, a liquid feeding pump for the suspensions, a vacuum pump, and a strand line with pelletizer. We tested at a screw speed of 250 rpm and a temperature profile of 20/230/250/ 250/230/220/220/200/200 °C.

In the first stage (zone 1) the polypropylene was fed into the main feed port and melted in the first mixing section (zone 2). The CNT suspension was dosed into the second feeding port (zone 3) into the PP melt by means of a liquid feeding pump. The ethanol from the suspension was then vented in two steps, using an atmospheric venting port in zone 4 and a vacuum venting in zone 9. The CNTs and the PP were thoroughly mixed and sheared in two mixing sections in zone 6 and zone 8.

In the first stage (zone 1) the polypropylene was fed into the main feed port and melted in the first mixing section (zone 2). The CNT suspension was dosed into the second feeding port (zone 3) into the PP melt by means of a liquid feeding pump. The ethanol from the suspension was then vented in two steps, using an atmospheric venting port in zone 4 and a vacuum venting in zone 9. The CNTs and the PP were thoroughly mixed and sheared in two mixing sections in zone 6 and zone 8.

One test was done with the pure polypropylene, one test with the addition of CNT suspension “1“ and one with CNT suspension “2“. It was clearly seen that the pressure increased when the CNT suspension was added. The pressure difference between the two different suspensions itself was not significant. The extruded material was then formed into a strand, cooled down in a water bath and cut into pellets by a pelletizer. Using a mini injection moulding machine those pellets were injection moulded into test specimens like discs and DMA bars for further investigations.

A microscopic picture taken from specimens made from the PP compound containing 0.5% CNT from suspension “1“ showed no agglomeration to be seen and the CNTs seemed to be evenly distributed in the polymer matrix. A microscopic picture taken from the PP compound containing 0.5% CNT from suspension “2“ showed a large amount of agglomerates. The dispersion seemed to be much worse than the results from suspension “1“.

The result of these tests showed significant differences between the compounds made with the differently functionalized CNTs, and proved that there is significant scope for safe testing of CNT compounds with extrusion equipment in a lab environment.

For additional details about the equipment, conditions, methods, as well as microscopic pictures and configuration charts, read the application note Compounding of Carbon Nanotube (CNT) Suspensions with Polypropylene.

Leave a Reply