A manufacturer of precision optical equipment designed a plastic cover for a device with specifications for chemical composition, surface texture, color and optical transmission. Briefly, the cover was to be made from a polycarbonate – acrylonitrile butadiene styrene (PC-ABS) blend with sufficient titanium dioxide to provide a slightly off-white color and optical transmissivity less than 0.01% T over a wide spectral range – from the UV into the near-infrared. The opacity was required to prevent ambient (room) light from entering the optical device and interfering with low light level measurements. Initially, all parts supplied met the specifications and the product provided satisfactory performance.

A manufacturer of precision optical equipment designed a plastic cover for a device with specifications for chemical composition, surface texture, color and optical transmission. Briefly, the cover was to be made from a polycarbonate – acrylonitrile butadiene styrene (PC-ABS) blend with sufficient titanium dioxide to provide a slightly off-white color and optical transmissivity less than 0.01% T over a wide spectral range – from the UV into the near-infrared. The opacity was required to prevent ambient (room) light from entering the optical device and interfering with low light level measurements. Initially, all parts supplied met the specifications and the product provided satisfactory performance.

A re-engineering project was subsequently initiated to reduce costs and make the product more competitive. Alternate suppliers for various parts, including the cover, were asked for quotations. A new supplier underbid the original cover supplier, and the test parts met all the requirements for opacity. Production was shifted to incorporate this new supplier.

Shortly thereafter, the product began to fail critical performance tests. The failures were immediately traced to ambient light causing elevated backgrounds, strongly affecting low level optical measurements. Visual inspection of the covers did not reveal apparent differences from the original, but various control experiments led to tracing of the failure to the new cover. A Root Cause Analysis using many techniques was undertaken to quickly identify and contain the issue.

Manufacturers employing plastic parts routinely face the challenge of analyzing failed parts to determine the root cause and corrective actions. The tools used to perform this analysis often include infrared and Raman spectroscopy for chemical composition, UV-Visible spectroscopy for color and optical transmissivity, and thermal analysis for determination of physical properties.

The manufacturer conducted several experiments to find the root cause of the failed plastic cover. In this article we will discuss the UV-Visible Spectroscopy and the Thermogravimetric Analysis (TGA) experiments. In our next article we will cover FT-IR and FT-Raman analyses.

UV-Visible Spectroscopy

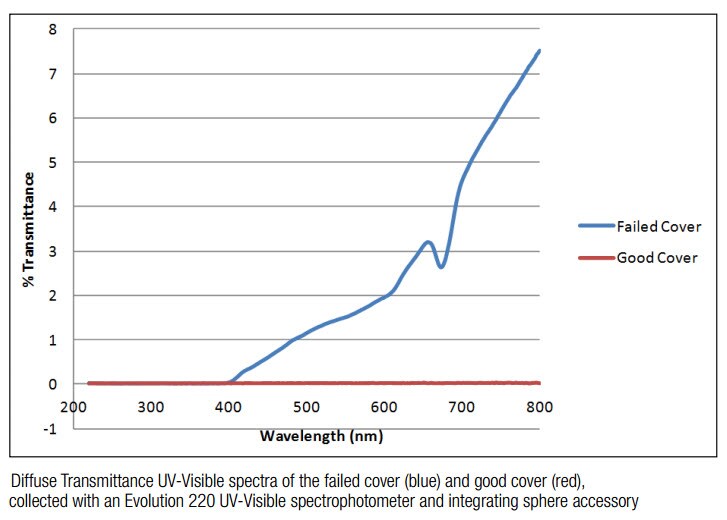

Diffuse transmission measurements of the original cover and failed cover were performed using a UV-Visible spectrophotometer and integrating sphere.

The cover by design contained significant quantities of particulates that would efficiently scatter any transmitted light. For this reason, transmittance was measured with an integrating sphere. Samples of covers from both good and failing devices were placed at the transmittance port of the integrating sphere and spectra were collected from 220 to 800 nm.

Essentially no transmittance was measurable through the good cover. In contrast, a significant transmittance through the visible part of the spectrum, greater than 7% T, was measured from the failing cover. This clearly explained the poor performance – the light leak – of the device under ambient conditions, but did not identify the root cause.

Thermogravimetric Analysis (TGA)

Small pieces of the two covers were then measured with a thermogravimetric analyzer to determine bulk composition. The samples were heated from ambient temperature to 650 °C at 20 °C/min under N2 purge, then cooled to 550 °C, and heated again to 1000 °C at 20 °C/min with air purge.

The initial heating ramp under nitrogen pyrolyzes the organic component of the covers, and the final temperature ramp in air burns the remaining organic components leaving only oxides of the inorganic content. The organic decomposition profiles of the two covers were nearly identical, indicating that both had the same plastic composition. However, the good cover had residual inorganic component representing 5.4% by weight, while the failed cover had an inorganic component of only 2.2% by weight. This indicated a significant difference in the inorganic filler amounts between the covers and provided a strong clue as to the source of the light leak.

So two experiments down and we are still not sure about the cause of the failure. Next week’s article will address FT-IR analysis and FT-Raman analysis and we will reveal the conclusion. If you can’t wait you can download the application note, which includes spectra, references, and instruments used.

Leave a Reply