Editor’s Note: This is the last of a five-part webinar series on general extruders and mixers for characterizing and formulating your polymer materials using rheology, viscometry, mixing and extrusion technologies. Watch for a webinar every Tuesday in March.

Powder injection molding materials consist of compounded materials – a mixture of a binder system and a metal or ceramic powder. From the compounding process, you get pellets, and these pellets are then used in injection molding machines to inject the materials into a mold. The binder is then removed by temperature or a chemical process and the part that remains goes through sintering to get to the final stage.

These materials are usually relatively small, high in shape complexity, high in strength, and demand moderate to close dimensional tolerances. The process can be costly and the industry is competitive, so quality control and testing is of utmost importance. Torque rheometers are used to help meet those quality control demands.

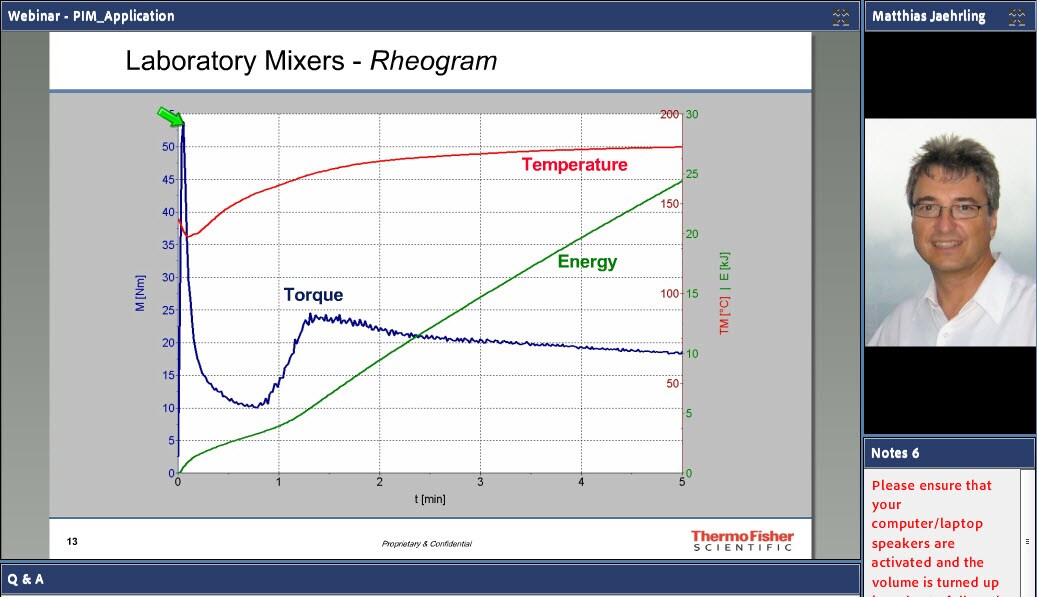

Torque rheometers with laboratory mixers and laboratory extruders are down-scaled production machines, which enable the simulation of production processes in a lab environment. This measuring method allows testing and comparing of materials close to production conditions.

This webinar gives a short introduction into the powder injection molding process and discusses how:

- laboratory mixers are used in the powder injection molding field

- twin screw extruders are used for compounding in feedstock production

- micro injection molding and sample preparation are done for mechanical testing

- capillary rheology is used for characterization of optimized flow properties

Learn about the different applications for rheometers, laboratory mixers, and twin-screw extruders, as well as see how the instruments work and results of testing done in this 50-minute webinar.

Click here to watch the Webinar: MIM/PIM Application – Mixer, Compounding, Rheology

Here are links to the full series:

- Extrusion Rheology – Usage of the Torque Rheometer

- Twin Screw Compounding – Introduction and Scale-Up

- Downstream Options for Extrusion

- Mixer Test – A Versatile Tool for Polymer Processing

- MIM/PIM Application – Mixer, Compounding, Rheology

Leave a Reply