SEM EDS Microanalysis

Today’s academic labs analyze materials using both scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDS), and they want fast, reliable results. By making it possible for users to quickly and easily acquire the data they need, universities can reduce user training, serve more researchers, accelerate research results, and future-proof instrument investment.

SEM EDS Challenges

Until recently, however, SEM-EDS microanalysis was considered difficult and somewhat involved. To obtain elemental data in addition to structural data, researchers were required to switch between separate PCs, software, and user interfaces often sold and maintained by different vendors. Not only was this process inefficient, but it was also complex—forcing lab managers to spend considerable time training users on the two different techniques and software.

Integrated EDS Analysis

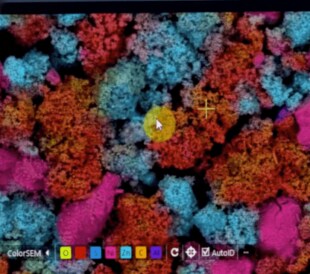

By moving to an instrument that combines EDS microanalysis with ColorSEM technology, researchers can eliminate many of the steps required using conventional EDS. Elemental data can be obtained directly from within the SEM image, eliminating setup time and the need to switch between two different systems. What’s more, ColorSEM is always on, collecting elemental data along with structural data about the sample. Researchers simply click on the image to get the compositional data they need, and they’re done. In fact, integrated EDS analysis using ColorSEM technology is twice as fast compared to conventional EDS analysis, dramatically increasing academic lab productivity.

Integrating EDS analysis with ColorSEM technology reduces the number of steps in the EDS workflow, enabling researchers to obtain elemental information two times faster than with conventional EDS.

While speed and ease-of-use are major advantages, there are other benefits as well. For one, integrated EDS with ColorSEM is more cost-effective than traditional EDS. It decreases overhead by eliminating the need for two systems. It saves money by reducing training time and expanding SEM use to more users. And it eliminates the need for large, expensive EDS detectors that many labs rely upon to increase their throughput.

Analysis of a copper-nickel-zinc (Cu-Ni-Zn) alloy precursor. Using black-and-white images produced by an SEM (left), it’s difficult to identify different materials—especially when there are only small differences in backscattered contrast. By contrast, the ColorSEM image (right) presents each element as a different color, making it easy to distinguish all the materials in the sample. In a point-and-ID workflow, this is crucial information in order to select the relevant spots for further analysis.

Secondly, integrated EDS with ColorSEM provides more information than conventional SEM or EDS images can offer alone. SEMs generate greyscale compositional images, which can make it difficult to see whether different parts of the image are the same or different elements. By contrast, ColorSEM identifies elements as different colors. By clicking on each color, users can quickly determine the elemental composition of their sample.

Analysis of molybdenum oxide (MoO) on an antimony sulfide (SbS) substrate. With conventional EDS (left), it is difficult to match the spatial distribution of the two materials to the features of the sample. The ColorSEM image (right) is more precise than traditional EDS, thanks to morphology-based image segmentation. Moreover, ColorSEM takes into account the overlap between the Mo and S X-ray lines and is capable of accurately analyzing even challenging samples.

Benefits of Integrated EDS

Unlike traditional EDS, integrated EDS with ColorSEM also provides morphology-based image segmentation, giving researchers more accurate information about the distribution of specific elements. In the same way that the human eye uses rods and cones to detect both the silhouette and color of an image, the ColorSEM system is aware of the shapes it recognizes and assigns each of these shapes colors. With accurate data about the distribution of various elements, researchers can more easily answer questions such as why their material failed and how much contamination is present.

Integrated EDS analysis with ColorSEM transforms SEM-EDS analysis for busy academic labs, enabling them to extend this critical capability to more users. By making SEM-EDS technology as fast and intuitive as basic SEM imaging, universities can enhance their research programs and their reputation for excellence.

Our affordable new Axia ChemiSEM will help take SEM-EDS analysis to the next level. Learn more here.

EJ Vesseur is a product marketing manager at Thermo Fisher Scientific.

///

Subscribe now to receive Accelerating Microscopy updates straight to your inbox.

Speak with an expert: https://www.thermofisher.com/blog/microscopy/speak-with-an-expert/

Leave a Reply