Quality control with SEM

Scanning electron microscopes (SEMs) are powerful analytical tools that can capture nanometer-resolution images of a sample’s surface, while revealing the physical and chemical properties of materials with ease. For a typical quality control process, SEMs provide a comprehensive set of information including valuable structural, morphology, and topography data. Their performance is unrivaled in the energy dispersive spectroscopy (EDS) analysis space for fast and accurate elemental analyses.

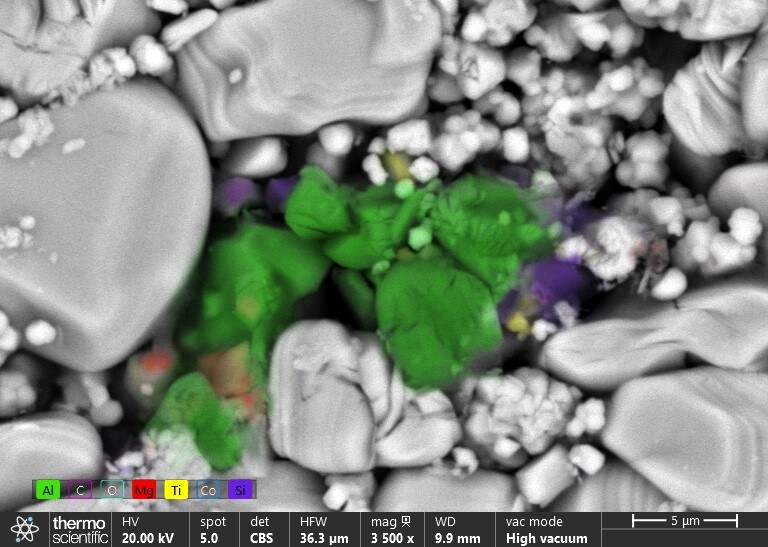

Scanning electron microscopes play a critical role in quality control processes. In this image, ChemiSEM reveals alumina and silica contaminants in LiCoO2 battery cathode.

Using a SEM, researchers can easily identify a range of novel materials, solve complex failure analysis problems and identify product defects for quality control in manufacturing. When combined with automated quality control processes, they can optimize the setup of samples, accelerate time to results and ensure the repeatability of measurements. The benefits a SEM provides for quality control processes include:

-

Superior resolution

SEMs provide superior resolution, depth of field, and magnification compared to optical microscopes. Because an electron’s wavelength is more than 10,000 times smaller than that of visible light, SEMs can achieve sub-nanometer (nm) resolutions and magnifications up to 300 times higher than an optical microscope. With the need to identify microscopic defects on increasingly small components, researchers often require an instrument with nanometer resolution to resolve fine details and identify faults. We offer a range of SEMs suited to scientists’ needs. For example, our powerful Verios 5 XHR SEM is capable of sub-nanometer resolutions at very low beam voltages. Our Apreo 2 SEM system provides nanometer and sub-nanometer resolution performance on materials ranging from nanomaterials, powders, catalysts and nanodevices to bulk magnetic samples. Our desktop SEMs, like our line of Phenom Desktop SEMs is capable of less than 10 nm resolutions, while our Phenom Pharos Desktop SEM can achieve resolutions up to 2.5 nm. Phenom Particle X TC and Phenom Particle X AM provide industry leading, turnkey automated solutions for fast and accurate EDS based micron particle classification used in industrial technical cleanliness and in additive manufacturing applications.

-

Comprehensive chemical analysis

When combined with energy dispersive X-ray spectroscopy (EDS), SEMs offer comprehensive chemical analysis—including elemental composition and concentration of samples. For a typical quality control process, EDS can assess the thickness and coverage of a sample coating, examine grain boundaries, and determine particle and grain sizes.Some EDS tools use automated quality control tools to provide an intuitive user experience and lower time to results. For example, Thermo Scientific ChemiSEM Technology offers instant chemical context for any observed faults and defects without requiring users to switch between systems. ChemiSEM is the complete integration of ColorSEM technology first developed by Thermo Fisher Scientific. ChemiSEM is always on, reducing time to results and revealing features that would have previously gone unnoticed. ChemiSEM increases user productivity by providing access to elemental information two to four times faster than conventional technologies. Quality control specialists can also test a vast range of materials depending on the capabilities of their SEM, and can analyze samples at high resolution while retaining the larger context of the sample.

-

Quality data, repeatable measurements.

SEMs can be calibrated to traceable standards, making it easy to replicate tests and analyze materials within a saved set of parameters, which is particularly useful when conducting compliance tests. For example, ISO 16232 and VDA 19 are two cleanliness standards for fluid systems in the automotive industry. When monitoring the cleanliness of these parts, quality control managers must be able to quickly identify the source of contaminants. Our SEMs provide a wide range of data to aid compliance, while also using automated quality control tools to ensure the repeatability of measurements. For example, our SmartAlign Technology is a self-aligning optics system, while our FLASH technology automatically fine tunes image focus. Features such as these make our SEMs easier to operate, while ensuring consistent data between experiments.

-

Fast, accurate, multi-scale quality control

With growing sample complexity and market demands, fast, accurate and multi-scale quality control is necessary in today’s laboratories. SEMs are widely used in a vast range of science and engineering fields, optimizing quality control processes, thanks to the versatility of these instruments.

At Thermo Fisher Scientific, we provide a range of SEM tools and techniques for multi-scale and multi-modal analysis across all of your quality control processes.

John Yorston is a Senior Product Specialist for SEM technology at Thermo Fisher Scientific.

//

Connect with an expert: https://www.thermofisher.com/us/en/home/global/forms/industrial/spectroscopy-materials-analysis-inquiries.html

Leave a Reply