X-ray photoelectron spectroscopy (XPS) is one of the most popular techniques for the analysis of polymer surfaces. It is a rapid and non-destructive technique for characterizing the surface of both conducting and insulating materials. It is quantitive, responsive to changes in chemical state, and extremely surface sensitive.

X-ray photoelectron spectroscopy (XPS) is one of the most popular techniques for the analysis of polymer surfaces. It is a rapid and non-destructive technique for characterizing the surface of both conducting and insulating materials. It is quantitive, responsive to changes in chemical state, and extremely surface sensitive.

We used an X-ray Photoelectron Spectrometer (XPS) System with a fully integrated, monochromated small-spot with depth profiling capabilities to map a crater defect on a painted surface. The crater appeared as a shallow bowl in the film with a raised center.

There are a range of problems that can affect painted surface production. These include gross faults such as flaking or delamination of the paint film and more subtle effects such as mottling or crater defects. Failures can occur for a variety of reasons. For example, contamination on the surface prior to coating can result in poor adhesion of the paint film. Alternatively problems could occur in the coating itself, such as segregation of the components once applied. Because XPS is a very surface sensitive technique, it is the ideal analysis tool for identifying the cause of a particular failure.

XPS images of the defect were collected by rastering the stage under the X-ray beam and collecting 128-channel snapshot spectra at each point. A one-click charge compensation system was used as the painted film was electrically insulating.

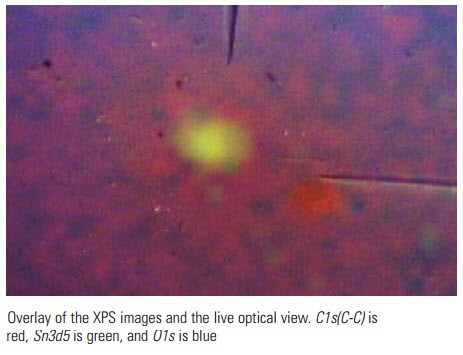

The defect was investigated by acquiring wide scan survey spectra from the center and edges to identify the elements present, and then mapped to generate XPS images for the chemistries present. It was seen that there was tin present at the center of the crater but nowhere else on the surface. In contrast there was depletion of the N1s and O1s signals at the same point. By peak fitting the spectra associated with each pixel of the image, chemical state images such as those shown for the C1s chemical states can were obtained. Again, it was seen that there was a difference in the carbon chemistry of the defect center compared with the rest of the crater. The C-C/C-H component was in greater concentration at the defect center.

The spectra that was retrospectively extracted from images suggested that the presence of the tin particle not only caused the physical defects (i.e. the crater structure), but also affected the chemistry of the paint film at that location.

Summary

By using XPS analysis a tin particle was identified at the center of a crater defect. This surface contaminant had affected the film chemistry at the center as well as physically forming the bowl shaped defect in the film. This chemical change was evidenced by an increase in the C-C/C-H chemistry at the same point, and corresponding decreases in nitrogen and oxygen concentrations. An overlay of the C1s(C-C), Sn3d5 and O1s XPS images and the optical view illustrated this conclusion.

Read the XPS Analysis of Defects on Painted Surface application note to see the spectra, XPS atomic percent images of the crater, and optical view of the crater defect.

Leave a Reply