The first post in this series, Laboratory-based XRF vs. Handheld XRF: What’s the Difference? explained that handheld XRF analyzers are designed for situations where immediate feedback is needed, whereas lab-based XRF analysis has a wider analytical range and is suited for more applications. The two primary types of lab-based XRF systems are Energy Dispersive X-ray Fluorescence (EDXRF) and Wavelength Dispersive X-ray Fluorescence (WDXRF). In this post, we’ll provide an overview of EDXRF.

EDXRF is a convenient technology to screen all kinds of materials for quick identification and quantification of elements with little or no sample preparation. Low cost of ownership and rapid elemental analysis of regular or irregular samples make EDXRF an attractive front-end analysis tool.

How EDXRF Works

EDXRF is designed to analyze groups of elements simultaneously. This type of XRF instrumentation separates the characteristic x-rays of different elements into a complete fluorescence energy spectrum which is then processed for qualitative or quantitative analysis. Filters positioned between sample and detector are used to improve signal, background reduction, and focus on certain regions of the spectra.

Direct Excitation vs. Indirect Excitation

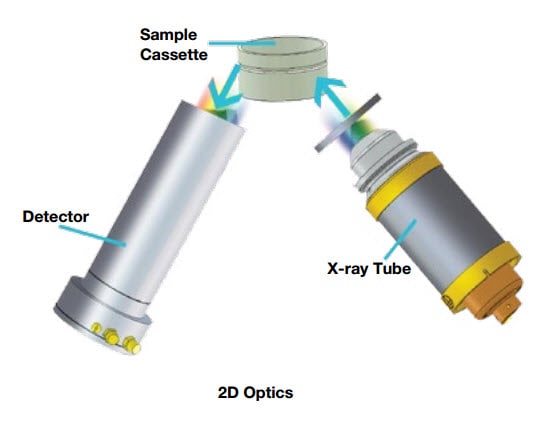

EDXRF instruments can have one of two types of excitation geometry; direct excitation, or 2D optics, and indirect excitation, also called 3D optics. The purpose of these geometries is to remove the background below the characteristic element lines in the spectrum and to increase the peak-to-background ratio (peak-to-noise). Both types rely on an energy dispersive detector and an x-ray tube; the difference is in the optic path.

Direct Excitation Geometry (2D optics)

In direct excitation geometry, the detector, sample and x-ray tube are positioned in the same plane. Primary x-rays from the tube are filtered according to which elements are being detected. The filtered primary radiation excites the sample elements and the resulting secondary radiation is detected by the detector.

Indirect Excitation (3D optics)

Indirect excitation features a 3D geometry with the x-ray tube, secondary target and sample in one plane, and the detector in a perpendicular plane. Instruments with 3D optics direct the primary x-rays first to a secondary target in the sample-target-tube plane, and then to the sample outside the plane. If reflections happen at exactly 90°, the primary radiation coming from the tube, which produces the background in the spectrum, is completely eliminated. However, irradiating the secondary target produces almost monochromatic radiation which is used to excite the sample elements. For EDXRF instruments with a tube power up to 50 Watts, the analytical performance of 2D and 3D are very similar.

Detectors

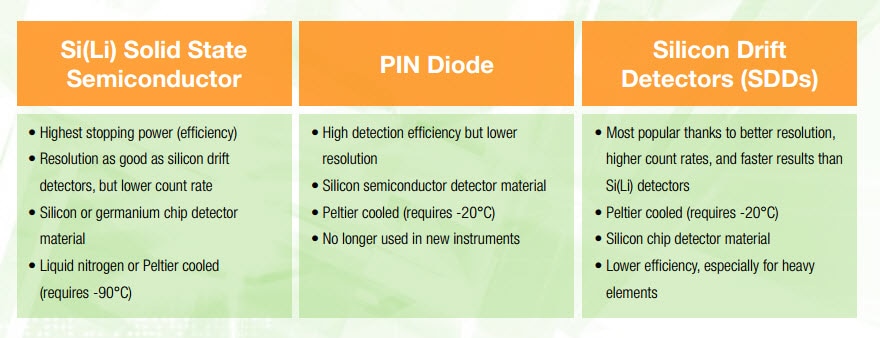

The resolution and elemental range achieved by EDXRF analyzers depends on the type of detector used.

Want to learn more about lab-based XRF? Download our free eBook: XRF in the Lab for the Non-Scientist.

Stay tuned for WDXRF: How Does It Work?

Leave a Reply