Installing an online elemental analyzer on bulk ore processing equipment enables early and accurate measurement of the grade of material being sent to the process plant and enables a decision to sort material that is below target grade and divert it to a low grade or waste stockpile. This enables a plant to increase the average grade of ore being processed to maximize metal recovery.

Installing an online elemental analyzer on bulk ore processing equipment enables early and accurate measurement of the grade of material being sent to the process plant and enables a decision to sort material that is below target grade and divert it to a low grade or waste stockpile. This enables a plant to increase the average grade of ore being processed to maximize metal recovery.

Continuous analysis of ore in base and precious metal applications is best accomplished using rapid online elemental analysis, with either PGNAA (Prompt Gamma Neutron Activation Analysis) or PFTNA (Pulsed Fast Thermal Neutron Activation).

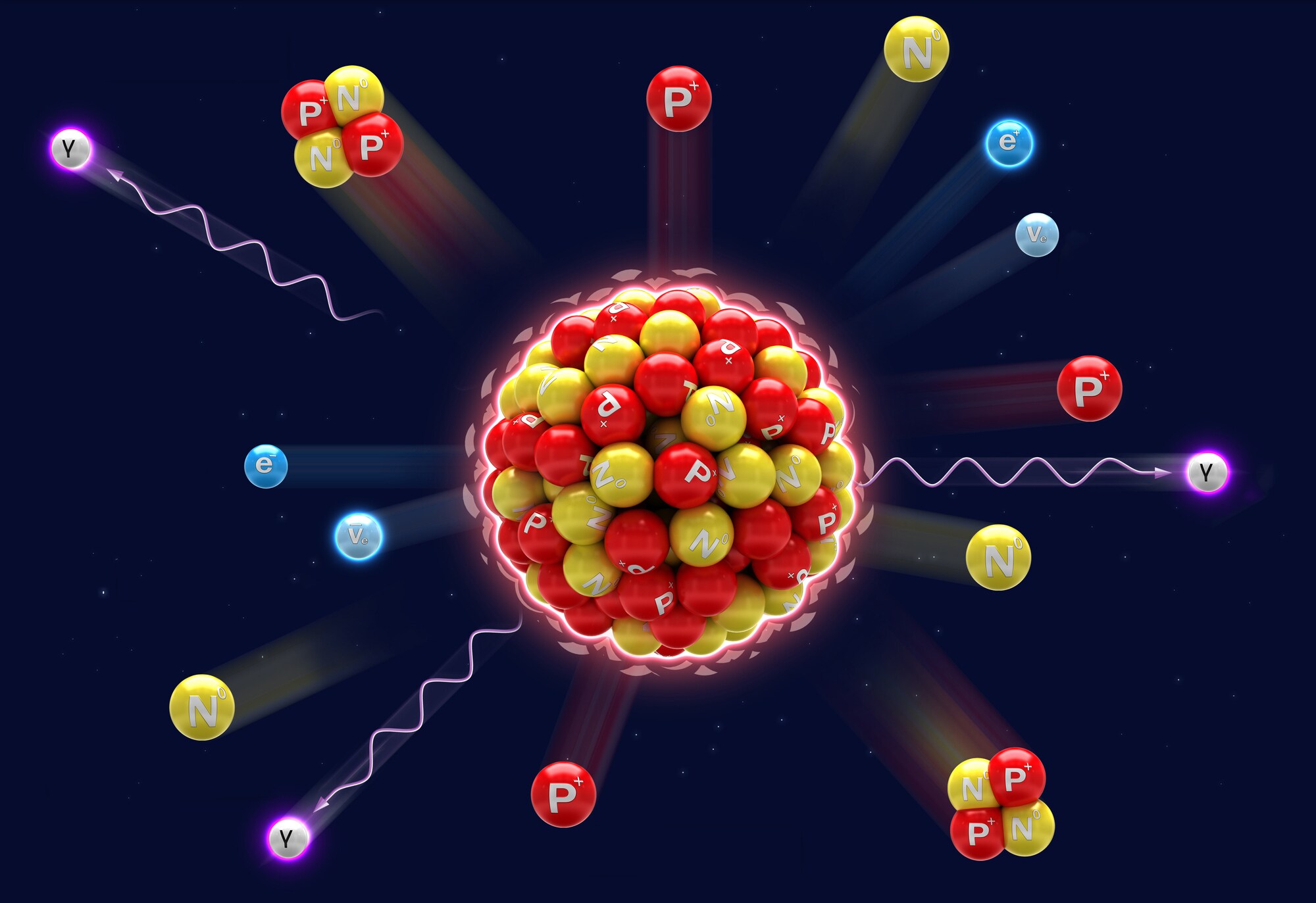

PGNAA and PFTNA are non-contact, non-destructive analytical techniques used to determine the elemental composition of bulk raw materials. Both of these techniques are known collectively as neutron activation analysis and function by bombarding materials with neutrons.

The neutrons interact with elements in the materials, which then emit secondary, prompt gamma rays that can be measured. Similar to X-ray fluorescence (XRF), each element emits a characteristic energy signature as it returns to a stable state.

PGNAA technology has been used for decades to provide online elemental analysis of material on conveyor belts and has been particularly prominent in the cement and coal markets. As the world progressively moves away from the use of isotopes, the mining industry is moving towards the use of a neutron generator as the source of neutrons instead of Cf-252.

PFTNA utilizes a neutron generator instead of Californium-252 (Cf-252) – a radioactive material – while retaining all other aspects of the PGNAAanalyzer.

Many online elemental analyzers have the flexibility to accommodate Cf-252 isotopes, up to 80µg, but there are significant advantages to using a neutron generator in an ore sorting application. To provide the level of accuracy and precision required to differentiate between very low grades of material a significantly higher specification analyzer than has traditionally been used in cement and coal markets is needed.

A neutron generator can provide a higher level of accuracy because of the following reasons:

- In applications that require a higher precision, the neutron output of the neutron generator can be increased to meet the needs of the application.

- A neutron generator can output neutrons at a consistent level, meaning that a neutron generator system will continuously deliver the same analytical performance throughout the lifetime of the system, whereas, Cf-252 naturally decays over time which leads to performance degrades.

- A neutron generator can be turned off when not in use, whereas Cf-252 continues to decay and emit neutrons continuously.

For more information about how to develop a bulk ore sorting system using an online elemental analyzer, read the application note: Bulk Ore Sorting in Base and Precious Metals.

To learn more about how PGNAA and PFTNA technology works, download our free eBook, A Guide to PGNAA and PFTNA Technology for Non-Scientists.

Leave a Reply