Search

Nanoparticle analysis overview

Nanometer-sized particles are present in many different materials, from food additives to high-performance metals to catalysts used for process optimization. As part of the process to enhance the properties of everyday materials, the characterization of nanoparticles involves the exploration and manipulation of structures at the nanoscale. Quantification of the composition, size, and shape of nanoparticles in these everyday objects is a crucial first step in furthering our understanding of the relationships between nanoparticles, performance, quality, and safety.

Automated nanoparticle analysis

Analyzing the nanoparticles present in everyday materials is a crucial part of ensuring safety and performance. Automation can help to not only accelerate everything from data acquisition to report generation but also simplify processes for more users, eliminate human error, and guarantee consistency from one experiment to the next.

The Automated Particle Workflow package provides all the necessary software and hardware for easy, automated, and unattended analysis of your sample with STEM and EDS, giving you the scientifically meaningful statistics that you need. APW contains a computer upgrade for the Talos TEM or Spectra (S)TEM, acquisition software (Thermo Scientific Maps 3 Software for (S)TEM and EDS, enabled by Thermo Scientific Velox Software), processing software (Thermo Scientific Avizo2D Software) on a dedicated data processing computer, and a bridge between the acquisition and processing software.

Automated nanoparticle analysis workflow

Dynamic software integration that streamlines chemical analysis

The Thermo Scientific Automated Particle Workflow improves the research and product development process for industrial, academic, and government labs by providing an all-in-one software package that streamlines chemical analysis workflows.

Automated particle workflow features

From automating tasks across a range of techniques and applications to increasing throughput and decreasing costs, the Thermo Scientific Automated Particle Workflow delivers comprehensive enhancements to help improve your analyses.

Automated Particle Workflow leads to higher productivity

Automated particle workflow can empower you to accelerate your time-to-results. Automated particle workflow’s fully automated solution expedites data collection by allowing you to rapidly screen new products and processes, while allowing you to analyze more samples in a shorter amount of time.

By automating routine nanoscale imaging and chemical analysis tasks overnight, automated particle workflow increases TEM productivity. This new-found availability frees up the TEM for other R&D, which can result in higher yield in finding smarter materials, and it can provide faster ramp-up for the research of new products.

Automated Particle Workflow decreases cost per measurement

Automated particle workflow can lower your cost per measurement through unattended, repeatable processes. Its automation capabilities allow you to quickly run complex workflows and eliminate the chance of human error inherent in manual processes, resulting in faster processes and more precise results.

Automated Particle Workflow is easy to use and can be unattended

Automated particle workflow is easy to use, so you do not need to be an expert microscopist to realize its benefits. Regardless of your experience level, you will be able to focus more attention on your materials science instead of the tool. Automated particle workflow’s integration with existing workflows and enhanced automation makes this software package efficient and user friendly, and it runs unattended.

Automated Particle Workflow can be used for a wide range of experiments

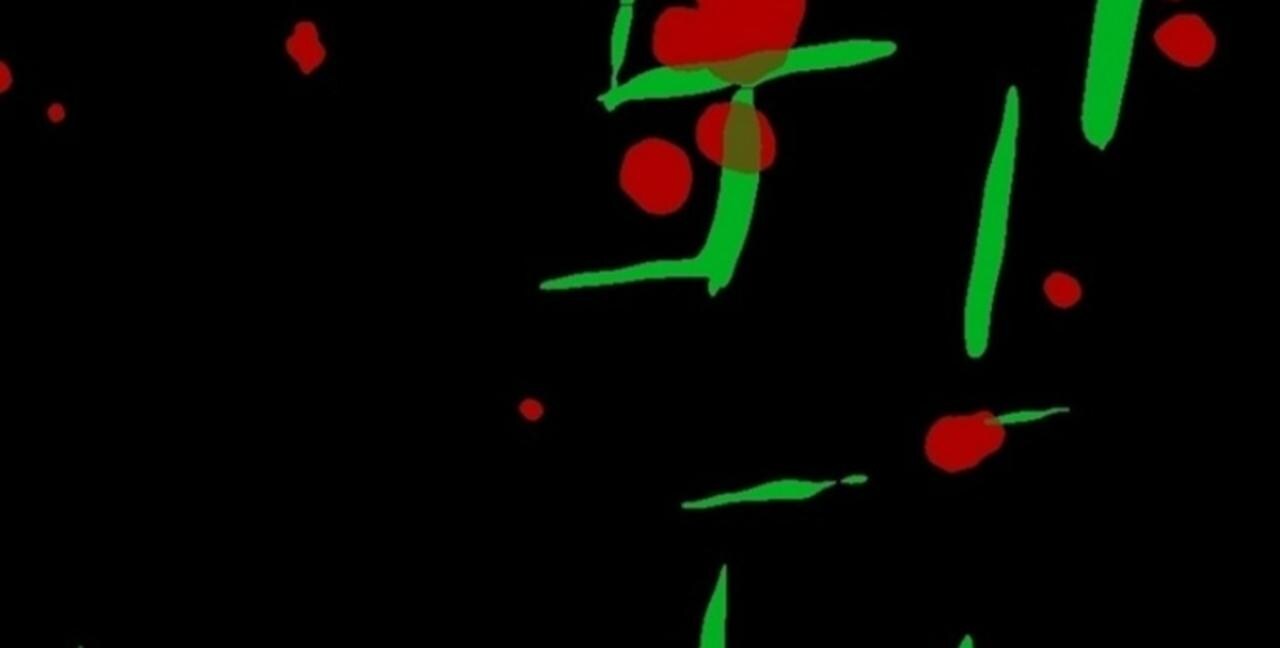

You can run a wide range of experiments on many different types of materials. The experimental techniques possible with automated particle workflow, including energy dispersive X-ray spectroscopy (EDS), support research related to metals, catalysis, foods, paints, asbestos, and more. Data collected and analyzed by Automated particle workflow includes nanoparticle morphology, chemical composition, and structural information (size, shape, distribution), allowing more research questions to be answered and, ultimately, enhancing product quality.

Nanoparticle analysis webinars and videos

Join us for exciting events and webinars coming up soon that cover a wide range of volume electron microscopy (vEM) topics. These events offer the opportunity to learn from experts in the field, network with volume electron microscopy community, and gain valuable insights into the latest trends and developments.

Advanced characterization of steels at the nano and micro scale

On-demand

Speakers: Hui (Maggie) Shi, Mélanie Gauvin, and Davit Melkonyan

Research engineers in the Materials Characterization and Testing Department of OCAS

Steel is vital for the durable infrastructure development needed for growing populations, provides affordable housing and mobility solutions, and is indispensable for energy generation and distribution. Due to its central role in making modern society sustainable, manufacturers are preparing the next generation of stronger, lighter, and more sustainable steel. This product development requires testing at micro and nanoscale.

OCAS, a joint venture between ArcelorMittal and the Flemish Region, is a research center active in metallurgy, coating, and steel application development.

This on-demand webinar highlights examples of advanced microscopy techniques applied to steel research at OCAS.

Watch this webinar to learn about:

- How automated particle workflow facilitates statistical precipitate analysis in steel research

- In-depth characterization of micro/nanometer-sized austenite domains by combining EPMA and EBSD techniques

- Grain boundary and precipitate analysis in various steels using atom probe tomography

Automated particle size analysis for TEM

On-demand

Speaker: Maarten Wirix, Thermo Fisher Scientific

Key learning objectives:

- How to run your TEM 24/7 – unattended

- How to significantly improve repeatability of your particle analysis on the nm scale

- How to remove repetitive manual analysis and operator bias

- How to quickly acquire statistics

Automated nanoparticle analysis blogs

Imaging and analyzing nanoparticles in an easy way: An exploration

Effectively examine statistically relevant data, no matter the nanoparticle type.

Typically ranging from 1 to 100 nanometers (nm), these particles can be found in materials in almost every modern-day industry imaginable. Their broad applicability in materials is widely due to their unique chemical properties, high surface area, and nanoscale size. Their reactivity and bonding properties make these particles a frequent additive in various industries, including food products, cosmetics, energy based research, aerospace engineering, and environmental applications. Therefore, the quantification and characterization of chemical properties of nanoparticles within a material are crucial first steps to designing materials that are more intentionally designed, structurally stable, and safer for the public.

Automated nanoparticle analysis blogs

For Research Use Only. Not for use in diagnostic procedures.