Search

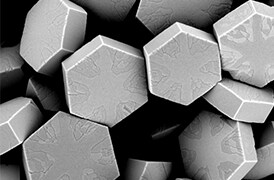

Tanto si se estudian nuevos materiales como si se intenta encontrar las causas fundamentales de los fallos, la caracterización altamente localizada de muestras cada vez más complejas con características cada vez más pequeñas es cada vez más importante. De hecho, a menudo se requiere una caracterización subsuperficial o tridimensional para comprender por completo las propiedades materiales de una muestra. Esto puede ser especialmente útil para materiales heterogéneos o para la detección y caracterización de inclusiones y precipitados. La instrumentación DualBeam (haz de iones enfocado, microscopía electrónica de barrido, FIB-SEM) permite la adquisición de conjuntos de datos 3D de alta calidad, a resolución de nanómetro, mediante cortes en secciones en serie (aplicación secuencial de adquisición de imágenes SEM y fresado FIB).

FIB de plasma (PFIB)

A menudo, en el caso de los grandes volúmenes, inaccesibles con los instrumentos convencionales de FIB de galio, son necesarios para obtener resultados representativos y estadísticamente relevantes debido a la información contextual adicional que proporciona una muestra grande. Los instrumentos de FIB de plasma, como el Thermo Scientific Helios G4 PFIB DualBeam y el Thermo Scientific Helios Hydra DualBeam, ofrecen un excelente rendimiento de alta corriente que permite conjuntos de datos 3D de gran volumen y alta calidad totalmente automatizados en una gran variedad de modalidades. Además, la tecnología de fuente de iones múltiples del Helios Hydra DualBeam le permite elegir la mejor fuente de iones para cada muestra y caso de uso en particular.

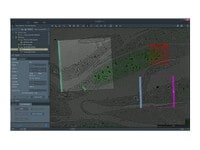

El corte en secciones en serie del FIB de plasma puede proporcionar información sobre el contraste de materiales (con adquisición de imágenes de retrodispersión de electrones), información de composición (con espectroscopía de energía dispersiva) e información microestructural y cristalográfica (con difracción de retrodispersión de electrones). Estos datos se pueden visualizar con el software Thermo Scientific Avizo, que ofrece una solución de flujo de trabajo única para la caracterización y el análisis 3D avanzados de mayor resolución a escala de nanómetros.

PFIB láser

El sistema PFIB láser Thermo Scientific Helios 5 va más allá de la FIB de plasma normal para realizar el corte en secciones transversal y la caracterización en 3D de volúmenes aún mayores, a escala milimétrica (con >una eliminación de material grueso 15.000 veces más rápida que la FIB de galio). También facilita el procesamiento de materiales que suelen ser difíciles para el fresado del haz de iones, como la carga y los materiales sensibles al haz, con un daño mínimo.

Carcasa de filtro de aceite de automoción (un compuesto de fibra de vidrio/polímero) con imágenes en el Helios Hydra DualBeam y reconstruida en un volumen 3D en Avizo Software. El ancho del campo horizontal es de 350 µm.

Muestra de tejido incrustada en el Helios Hydra DualBeam y reconstruida en un volumen 3D en Amira Software, destacando la capacidad del Helios Hydra DualBeam para realizar una caracterización 3D de alta calidad de materiales orgánicos.

Carcasa de filtro de aceite de automoción (un compuesto de fibra de vidrio/polímero) con imágenes en el Helios Hydra DualBeam y reconstruida en un volumen 3D en Avizo Software. El ancho del campo horizontal es de 350 µm.

Muestra de tejido incrustada en el Helios Hydra DualBeam y reconstruida en un volumen 3D en Amira Software, destacando la capacidad del Helios Hydra DualBeam para realizar una caracterización 3D de alta calidad de materiales orgánicos.

Control de calidad

El control y garantía de calidad son esenciales en la industria moderna. Ofrecemos una gama de herramientas de EM y espectroscopía para el análisis multiescala y multimodal de defectos, lo que le permite tomar decisiones fiables e informadas para el control y la mejora de procesos.

Investigación sobre materiales fundamentales

Se investigan nuevos materiales a escalas cada vez más pequeñas para lograr el máximo control de sus propiedades físicas y químicas. La microscopía electrónica proporciona a los investigadores información clave sobre una amplia variedad de características materiales a escala nanométrica.

Investigación de baterías

El desarrollo de baterías se realiza mediante análisis multiescala con microCT, SEM y TEM, espectroscopía Raman, XPS y visualización y análisis 3D digital. Aprenda cómo este enfoque proporciona la información estructural y química necesaria para crear mejores baterías.

Investigación sobre polímeros

La microestructura polimérica determina las características y el rendimiento del material a granel. La microscopía electrónica permite un análisis exhaustivo en microescala de la morfología y composición de los polímeros para aplicaciones de control de calidad e I+D.

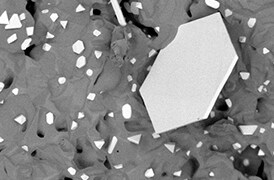

Investigación sobre metales

La producción eficaz de metales requiere un control preciso de las inclusiones y precipitados. Nuestras herramientas automatizadas pueden realizar varias tareas cruciales para el análisis de metales, incluyendo el recuento de nanopartículas, el análisis químico EDS y la preparación de muestras de TEM.

Gas y petróleo

A medida que la demanda de petróleo y gas continúa, existe la necesidad constante de una extracción eficiente y eficaz de hidrocarburos. Thermo Fisher Scientific ofrece una amplia gama de soluciones de microscopía y espectroscopía para una gran variedad de aplicaciones de la ciencia del petróleo.

Fibras y filtros

El diámetro, la morfología y la densidad de las fibras sintéticas son parámetros clave que determinan la vida útil y la funcionalidad de un filtro. La microscopía electrónica de barrido (SEM) es la técnica ideal para investigar rápida y fácilmente estas características.

Investigación geológica

Las ciencias geológicas están basadas en la observación uniforme y precisa de múltiples escalas de características dentro de las muestras de roca. SEM-EDS, combinado con software de automatización, permite el análisis directo a gran escala de la composición de la textura y los minerales para la investigación de la petrología y la mineralogía.

Servicios de microscopía electrónica para

la ciencia de materiales

Para garantizar un rendimiento óptimo del sistema, le proporcionamos acceso a una red de expertos de primer nivel en servicios de campo, asistencia técnica y piezas de repuesto certificadas.