This is the second blog post in the Biopharmaceutical Basics series.

The ultimate goal of biopharmaceutical development and manufacturing is to deliver the highest-quality product at the lowest cost — in the shortest time possible. However, large molecule drugs are highly complex, leading to analytical challenges throughout the development pipeline to quality control and release.

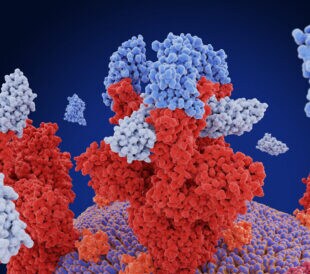

Monoclonal antibodies (mAbs) and other complex biological drug products, such as antibody-drug conjugates (ADCs), must be exhaustively characterized to ensure the safety and efficacy of a batch before release. The Multi-Attribute Method (MAM) aims to address these challenges using the power of high-resolution, accurate-mass (HRAM) mass spectrometry to improve process control for biopharmaceutical manufacturing.

Monoclonal antibodies (mAbs) and other complex biological drug products, such as antibody-drug conjugates (ADCs), must be exhaustively characterized to ensure the safety and efficacy of a batch before release. The Multi-Attribute Method (MAM) aims to address these challenges using the power of high-resolution, accurate-mass (HRAM) mass spectrometry to improve process control for biopharmaceutical manufacturing.

If you’re new to the world of biopharma analysis, here’s a helpful overview on MAM and what’s available today.

What is MAM?

MAM is a peptide mapping-based method that takes advantage of high-resolution mass spectrometric data. High-resolution mass spectrometry provides the accurate mass information aiding identification of product quality attributes and consequent quantitation and monitoring, which leads to a more comprehensive biomolecule process understanding, allowing for better process control in manufacturing. It’s a relatively new analytical approach that is particularly well suited to biotherapeutics QC (publication in mAbs [2015]).

How does MAM work?

MAM is based on traditional peptide mapping. To begin building the method, the biotherapeutic must first be digested into peptides. This critical step requires 100 percent sequence coverage, high levels of reproducibility, and minimal process-induced modifications (e.g., deamidation and oxidation).

The resulting peptides are separated using liquid chromatography (LC) and detected using high-resolution accurate-mass (HRAM) MS. The data is then processed using sophisticated software tools.

Why is MAM important?

HRAM MS for MAM provides a comprehensive view of the critical quality attributes (CQAs) present in biotherapeutics, down to the individual amino acid of each molecule. Detailed information can be obtained on post-translational modifications (PTMs), glycosylation profile, the presence of low-level sequence variants, and minute concentrations of process impurities. High-resolution accurate-mass data makes access to this detailed information possible without the need for full chromatographic separation.

Another key component of MAM is new peak detection, which enables new peaks (impurities) to be detected when compared to a reference sample. This data analysis step is essential for using MAM as a QC release method. MAM is a singular approach that has the potential to consolidate multiple analyses from QC to batch release, enabling scientists to work toward consistent biotherapeutic products across the process, in line with Quality by Design (QbD) principles.

What are the benefits of MAM?

A well-developed MAM enables identification, quantitation, and monitoring of multiple CQAs simultaneously as well as new peak detection. The benefits of an optimized and standardized Multi-Attribute Method for characterization of biologics and later-stage quality control include:

- High-resolution MS data for absolute identification and confidence in analytical control over quality

- A single method providing the same or superior product quality information instead of many traditional methods and techniques

- A single assay that offers cost and time savings, as well as fewer SOPs and instruments to maintain

- Offering consistently reliable analytical processes on multiple instruments across different development sites, from research and development to manufacturing and QC

- Accepting and standardizing MAM from development into QC space will offer peace of mind when preparing regulatory filings

A fit-for-purpose MAM solution

Being the leading biotherapeutic solution provider and a trusted partner, Thermo Fisher Scientific has been working closely with industry leaders to develop a seamless, fit-for-purpose MAM solution. Read the application note to learn how the National Institute of Bioprocessing Research and Training implemented the MAM 2.0 Workflow and evaluated repeatability, reproducibility, and linearity analysis for selected CQAs.

To learn more, contact Thermo Fisher or visit the dedicated MAM website.

Additional resources in the Biopharmaceutical Basics blog series

Biopharmaceutical Characterization: A Biopharmaceutical Basics Overview

Oligonucleotide Therapeutics: A Biopharmaceutical Basics Overview

mRNA-based Therapeutics and Vaccines: A Biopharmaceutical Basics Overview