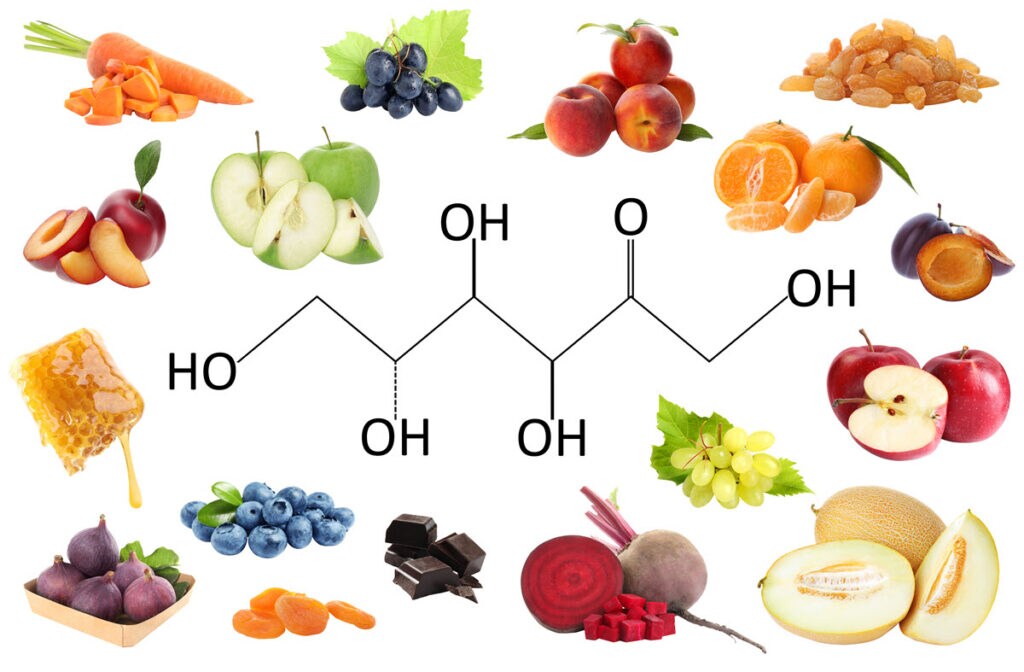

Since even neutral carbohydrates can be readily ionized in high pH conditions, ion chromatography (IC) has become an indispensable analytical tool in the food and beverage (F&B) and biopharmaceutical industries. In F&B, IC helps manufacturers precisely measure sugars, sugar alcohols, and other carbohydrates in products ranging from soft drinks to functional foods. This capability is crucial for nutritional labeling, quality control, and developing new formulations.

In the biopharma sector, IC plays a vital role in the analysis of analytes such as glycans, which are critical for the efficacy and safety of biotherapeutics. It allows researchers and quality control teams to characterize and monitor these molecules throughout the drug development and manufacturing processes.

However, there are a number of options for IC elution technique (see table 1) and choosing the right IC system is critical in supporting a method for obtaining clear, actionable data at the speed needed by the analyst.

Table 1. Carbohydrate IC elution techniques*

| Elution technique | Target Carbohydrate Analytes | Notes |

| Carbonate/bicarbonate | N/A | Carbonate eluents are not suitable for carbohydrate analysis, including organic acids. |

| Isocratic hydroxide (NaOH) – manually prepared | Monosaccharides | Carbonate contamination can cause shifts in retention time. Degas eluent immediately after preparation and blanket under an inert gas. |

| Eluent generator (KOH) | Mono- and di-saccharides | No contamination as eluents are produced in-line. Ability to run gradients with an isocratic pump. Maximum 100 mM limits the ability to elute larger carbohydrates. |

| Dual eluent generator (KOH/KMSA) | Mono-, di-, some oligosaccharides | Benefits of eluent generation for larger carbohydrates. |

| Proportioned gradients (NaOH/NaOAc) | All carbohydrates, including high mass and highly sulfated oligosaccharides, plus sialylated glycans | Traditional method with highest elution strength. Requires expertise in eluent preparation and purity of chemicals used. |

Eluent generator systems: advancing precision

Eluent generation (RFIC-EG) systems represent a significant advancement in using IC for carbohydrate analysis. These systems produce high-purity potassium hydroxide (KOH) eluents on-demand, offering several key benefits over manually prepared eluents.

The primary advantage of RFIC-EG systems is the elimination of carbonate contamination, a common issue with manually prepared sodium hydroxide (NaOH) eluents. This contamination can cause shifts in retention time, affecting the accuracy and reproducibility of analyses. RFIC-EG systems produce consistently pure KOH solutions, ensuring stable retention times and reliable results.

In F&B applications, RFIC-EG excels at analyzing mono- and disaccharides, crucial for nutritional labeling and quality control of beverages and processed foods. For the biopharma industry, these systems are valuable in analyzing simpler carbohydrate structures in drug formulations and fermentation broths.

Standard RFIC-EG typically have a maximum concentration of 100 mM KOH, which can limit their ability to elute larger carbohydrates. However, an advancement in this technology ꟷ the dual eluent generator (Dual EGC) system ꟷ addresses this limitation. Dual EGC combines KOH and potassium methanesulfonate (KMSA) generation, capable of producing up to 200 mM KOH and 200 mM KMSA. This significant increase in eluent strength extends the range of analyzable carbohydrates to include oligosaccharides, bridging the gap between standard EGC and traditional proportioned gradient methods.

Eluent generators offer the flexibility to run gradients using an isocratic pump, simplifying system setup. This capability, combined with the increased strength of dual EGC systems, makes these technologies suitable for a wide range of carbohydrate analyses in both F&B and biopharma sectors, from simple sugars to larger oligosaccharides.

Proportioning pump systems: unmatched versatility

While eluent generator systems have revolutionized many aspects of IC, proportioning pump systems remain the standard for the widest range of carbohydrate analyses. These systems offer unparalleled flexibility and power, typically combining solutions of manually prepared sodium hydroxide (NaOH) and sodium acetate (NaOAc/NaOH).

Proportioning pumps allow for the precise mixing of multiple eluents in real-time, creating gradient profiles that can be fine-tuned to separate challenging carbohydrate mixtures. This capability is crucial when dealing with samples containing a wide range of carbohydrate types and sizes.

In the F&B industry, proportioning pump systems excel in oligosaccharide analysis. They can separate mixtures of dietary fibers, prebiotics, and sugar alcohols in functional foods and nutraceuticals. The ability to create custom gradients allows for fine tuning the trade-off between analyte resolution and speed of analysis.

For the biopharmaceutical sector, these systems are indispensable for complex glycan analysis. Biotherapeutic proteins often carry intricate glycosylation patterns that are critical to their efficacy and safety. Proportioning pump systems, using NaOH/NaOAc gradients, can separate highly sulfated carbohydrates, sialylated glycans, and high molecular weight oligosaccharides that are challenging or impossible to analyze with other methods.

However, these advantages come with increased complexity. Manually prepared eluents require expertise in the lab, and in chemical sourcing, to ensure purity and consistency. Despite this challenge, for the most demanding carbohydrate analyses in both F&B and biopharma applications, proportioning pump systems remain the method of choice, offering a level of versatility and analytical power that is yet to be matched by other techniques.

Choosing the right system for your needs

Selecting the appropriate IC system for carbohydrate analysis depends on several factors, including the complexity of your samples, the specific analytes of interest, and your laboratory’s requirements for speed, ease of use, and analytical power.

For routine analysis of simple sugars in F&B applications, such as quality control of soft drinks or basic nutritional labeling, an eluent generator system (RFIC-EG) is often the ideal choice. These systems offer excellent reproducibility, ease of use, and are suitable for analyzing mono- and disaccharides without the need for complex eluent preparation.

If your work involves a broader range of carbohydrates, including some oligosaccharides, consider a dual eluent generator (Dual EGC) system. With its ability to produce higher concentrations of KOH and MSA, it bridges the gap between standard EGC and more complex methods, making it versatile for many F&B and biopharma applications.

For the most demanding applications, particularly in biopharma or advanced F&B research, a proportioning pump system remains the gold standard. If you’re analyzing complex glycans, highly sulfated carbohydrates, or need maximum flexibility in method development, this system’s unmatched versatility makes it the best choice despite the increased complexity in eluent preparation.

Consider these key questions, and Table 2 showing the capabilities of Thermo Fisher Scientific IC systems, when making your decision:

- What types of carbohydrates are you analyzing? (Simple sugars, oligosaccharides, complex glycans)

- How critical is ease of use and minimal eluent preparation?

- Do you need the ability to fine-tune separations for closely eluting compounds or to reduce analytical run-time?

- What level of method development flexibility do you require?

Table 2. Thermo Fisher Scientific IC Systems

| System | Carbohydrate Analysis Capabilities | Best suited for |

| Thermo Scientific Dionex Inuvion system | Not suitable* | Other IC applications |

| Thermo Scientific Dionex Inuvion RFIC system | Not suitable* | Other IC applications |

| Thermo Scientific Dionex Integrion system | Pulsed amperometric detection RFIC-EG | Routine analysis of mono- and disaccharides F&B quality control Basic nutritional labeling |

| Thermo Scientific Dionex ICS-6000 system | Pulsed amperometric detection RFIC-EG Dual EGC Proportioned gradients | Simple to complex carbohydrate analysis Oligosaccharide profiling Glycan analysis in biopharma Advanced F&B research |

Ultimately, the right system will balance your current analytical needs with potential future requirements, ensuring that your laboratory is equipped to handle both routine analyses and more challenging projects as they arise. Where future requirements are uncertain, it can often be best to choose the most flexible system that can support all possible elution methods: in this case the Dionex ICS-6000 is ideal, with the ability to upgrade and modify the system freely.

While this guide provides a foundation for understanding your options, expert advice is invaluable in making the final decision. Thermo Fisher Scientific’s sales and support representatives are eager to help you understand your needs and to recommend the most appropriate system for all your analytical and business requirements. Don’t hesitate to reach out to them.

Related information

Technical note: Eluent Preparation for High-Performance Anion-Exchange Chromatography with Pulsed Amperometric Detection

Brochure: Simplify carbohydrate analysis

Infographic: Simplify the complexity in carbohydrate analysis

Visit our LinkedIn page #IonChromatography #CarbohydrateAnalysis