The automotive industry makes extensive use of polyurethane adhesives, so you can understand why automotive manufacturers would question if the polyurethane adhesive being used during manufacturing is the proper material for the new lightweight materials they are encountering.

The automotive industry makes extensive use of polyurethane adhesives, so you can understand why automotive manufacturers would question if the polyurethane adhesive being used during manufacturing is the proper material for the new lightweight materials they are encountering.

FTIR spectroscopy is a common technique used for quality control in many industries so we wanted to conduct a test using that technique on marine adhesive, which is very similar to the types of adhesives used in the auto industry. The goal of test was to identify or confirm the identification of the adhesive in question to help ensure the right adhesive was being used for the task and it was meeting quality control requirements.

Fourier Transform Infrared (FT-IR) spectrometers are the standard for organic compound identification work in academic, analytical, QC/QA and forensics laboratories. FTIR spectroscopy is used to quickly and definitively identify compounds such as compounded plastics, blends, fillers, paints, rubbers, coatings, resins, and adhesives. It can be applied across all phases of the product lifecycle including design, manufacture, and failure analysis. This makes it a useful tool for scientists and engineers involved in product development, quality control, and problem solving.

We smeared a small amount of uncured polyurethane adhesive on the diamond crystal of a built-in ATR accessory in the FT-IR spectrometer. An ATR accessory operates by measuring the changes that occur in an internally reflected IR beam when the beam comes into contact with a sample. An IR beam is directed onto an optically dense crystal with a high refractive index at a certain angle. This internal reflectance creates an evanescent wave that extends beyond the surface of the crystal into the sample held in contact with the crystal.

In regions of the IR spectrum where the sample absorbs energy, the evanescent wave will be attenuated. The attenuated beam returns to the crystal, then exits the opposite end of the crystal and is directed to the detector in the IR spectrometer. The detector records the attenuated IR beam as an interferogram signal, which can then be used to generate an IR spectrum.

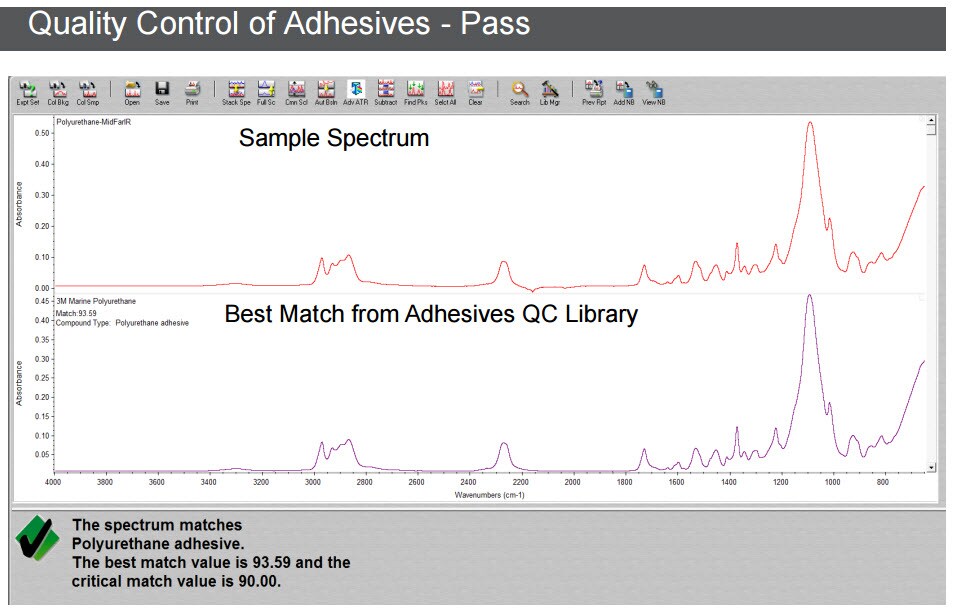

The adhesive spectrum was collected at 4 cm-1 resolution, coadding 32 scans (<1minute), and then compared to a library of reference adhesives, with the closest match displayed along with pass/fail results and acceptance values.

QC Compare results for the polyurethane adhesive showed a best match for a 3M marine adhesive in the class of polyurethane adhesives with the match value of 93.59 passing compared to an acceptance threshold value of 90.00, on a scale of 0- 100 (as seen here).

The QC Compare algorithm is different from a Library Search algorithm of which you may already be familiar. In Library Search for identification of unknown components, we looked for similarities between the unknown sample and library spectra; whereas in a QC Compare, for confirmation of the identity, we tried to enhance the differences.

As a negative challenge sample, we allowed the polyurethane to age in air for approximately one hour. Then we ran the spectrum of the aged sample through the QC Compare method.

As you can see below, the age sample failed the QC Compare test even though at first glance the spectrum was very similar to the fresh sample with the most obvious difference the slight decrease in the intensity of the nitrile band at 2275 wavenumbers.

We recently conducted a webinar on the Analysis of Automotive Adhesives Using FTIR Spectroscopy, and discussed the above example during the webinar. You can download the recorded 30-minute webinar here, which is available on demand until March, 2017.

Access the webinar now: Analysis of Automotive Adhesives Using FTIR Spectroscopy

Leave a Reply