As worldwide demand for high-quality steel continues, it’s important to avoid impurities that can degrade the finished product. Even microscopic amounts of foreign matter can significantly undermine the quality of the steel by reducing its strength and flexibility as well as its resistance to corrosion.

Impurities in steel manufacturing

Entrained slag or eroded refractory can contaminate the steel during refining. And every time a steel alloy is produced, natural impurities emerge as different components react with one another to form non-metallic compounds such as oxides and sulfides. By identifying the composition of the non-metallic inclusions, steel producers can work toward reducing or eliminating their source which improves final product quality.

Techniques for identifying steel impurities

Identifying steel impurities at the microscale typically involves combining two techniques: scanning electron microscopy (SEM) and Energy Dispersive X-ray Spectroscopy(EDS) analysis. Using an SEM, materials scientists can obtain greyscale images of their sample that show the contrast between the steel and any foreign substance as well as contrast within the foreign substance itself. By then switching to EDS analysis, they can study these impurities in more detail by analyzing their chemical composition.

Steel EDS analysis

Unfortunately, EDS analysis can be difficult for new users to learn. What’s more, combining SEM and EDS can be time-consuming because it requires users to switch back and forth between the two techniques using separate computers, software, and user interfaces.

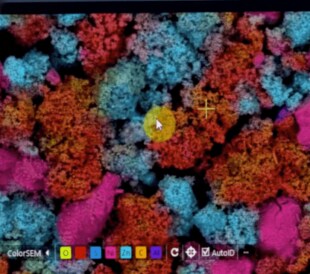

Thermo Scientific ColorSEM Technology addresses these issues by combining both techniques into a single tool. By building advanced color EDS technology directly into SEM imaging and analysis, ColorSEM Technology enables users to obtain instant elemental information about their samples without having to learn EDS analysis or switch between applications.

This map shows an oxide inclusion comprised of calcium aluminate liquid phase (purple) and crystals of solid magnesium oxide (green).

ColorSEM for steel analysis

A key benefit of ColorSEM Technology is that it improves productivity by delivering elemental information two- to four-times faster than conventional techniques. The technology is “always on,” meaning that EDS data is collected every time a sample is scanned, and the information is readily available whenever the researcher needs it. The elements are automatically identified and shown in color, and each element can be switched on or off to quickly assess its distribution.

Not only can researchers see the X-ray spectrum from the entire scan area of the SEM image, but they can also perform localized analyses to determine the percentage concentration of each element at different points or by following a line on the sample image. Information derived from these analyses can be used to identify compositional changes that occur during different steps of the steelmaking process—helping manufacturers to optimize their production process.

ColorSEM Technology enables manufacturers to discover defects that would otherwise go unnoticed, giving them the accurate data needed to optimize their production processes. The result is fewer impurities for every ton of steel as well as higher-quality steel products that underpin our lives.

Roger Maddalena serves as a market development manager for materials science at Thermo Fisher Scientific.

///

Speak with an expert: https://www.thermofisher.com/blog/microscopy/speak-with-an-expert/

Subscribe now: https://www.thermofisher.com/blog/microscopy/subscribe-to-accelerating-microscopy/

Leave a Reply