Dr. Michael Bruns of the Karlsruhe Institute of Technology presents the use of XPS in his research on nanomaterials and OLED components. He highlights, using examples, that XPS provides precise information on the chemical composition of modified surfaces, the precise location of the active compounds on the substrates, and precise justification of single reaction steps, even on biomaterial substrates. In the surface analysis group, the team has access to instruments doing X-ray Photoelectron Spectroscopy (XPS), Time-of-Flight Secondary Ion Mass Spectrometry (TOF SIMS), as well as a field emission scanning electron microscope (SEM). All instruments are accessible to samples via an inert gas transfer system.

Surface Analysis of OLED Components and Nanomaterials Via XPS

During this talk, three x-ray photoelectron spectroscopy (XPS) examples are explored:

- XPS speciation and ARXPS profiles of self-assembled monolayers

- Multilayer characterization via SPX sputter depth profiling of white OLEDs and GeO2 nanoparticles

- XPS speciation of the surface modification of biological substrates involving cellulose and SWCNTs

Start with self-assembled monolayers for biological applications showing immobilization on isolated surfaces. “If you use the Parallel ARXPS, you can get the information on binding energy and angle”; in this way, the monolayers are probed. The result is shown in the depth (nm) versus atomic concentration chart shown here, where the molecule has also been superimposed across the top of the chart. The double layer system of the molecule on the topmost layer is clearly shown, then the CH chain and finally the sulfur binding to the gold substrate. “I believe it’s the only method whose able to do to give such information in a non destructive manner to get the depth profile across 2 to 3 to 4 nanometers.” The results are double checked with a synchrotron source at ANKA.

Surface Analysis of OLED Components and Nanomaterials Via XPS

The second topic involved solution processed, white emitting tandem organic light-emitting diodes (OLEDs) with inverted device architecture. To confirm the structure, material must be removed from the surface, layer by layer, and this is down with an ion source to end up with a sputtered depth profile. A second sputtering example of Germanium nanoparticles in silicon dioxide layers is also presented, where the dopant profile was determined to be approximately 2.5 percent.

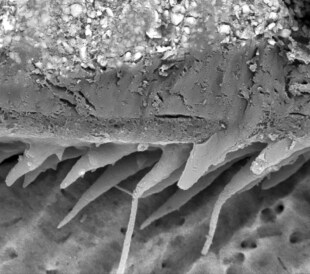

Dr. Bruns’ last example has to do with the functionalization of carbon nanotubes. “It is essential that you have high purity CNNT and polymers as you’ll need templates to prove the functionalization.” He shows examples that show the steps to functionalization while using the single reaction steps involved.

Several pertinent questions were asked during the Q&A period. In one of the questions, a listener asked about sample preparation, “Are there any special sample preparation steps required before XPS analysis?” and Dr. Bruns elaborates on sample prep for various materials for the Argonne cluster gun.

Another listener asked, “Are there any materials or compounds that cannot be analyzed by XPS?” and Dr. Bruns answers, “One element which is impossible to energize is Hydrogen, because it has no photoelectrons to expel.” He goes on to discuss that any material that is intended to be studied via XPS is high vacuum stable, because the analysis is always done in high vacuum or ultra-high vacuum.

Dr. Bruns’ talk is extremely useful for any researcher considering using XPS for the delicate study of surfaces.

Leave a Reply