Our last article discussed our presentation “Real Time Analysis of Copper Alloys using Handheld X-Ray Fluorescence Spectrometry,” given at the International Wrought Copper Council (IWCC) meeting in Osaka, Japan. The IWCC works for and with member companies across the world to support the copper and copper alloy fabricating industry. The last article answered the questions why metal/copper analysis is important, when should metals be analyzed, and what are the available methods for metal and alloys testing. Today’s article will focus on handheld X-ray fluorescence spectrometry technology when it comes to copper alloy grade identification.

Our last article discussed our presentation “Real Time Analysis of Copper Alloys using Handheld X-Ray Fluorescence Spectrometry,” given at the International Wrought Copper Council (IWCC) meeting in Osaka, Japan. The IWCC works for and with member companies across the world to support the copper and copper alloy fabricating industry. The last article answered the questions why metal/copper analysis is important, when should metals be analyzed, and what are the available methods for metal and alloys testing. Today’s article will focus on handheld X-ray fluorescence spectrometry technology when it comes to copper alloy grade identification.

The verification of metal alloys for quality assurance and quality control (QA/QC) has never been more important for product reliability and safety. From metal production through final product assembly, the potential for material mix-ups is real. With all types of manufacturing operations facing increasingly stringent safety regulations, today’s best practices include testing 100% of critical materials, including copper alloys.

X-ray fluorescence spectroscopy (XRF) is a non-destructive analytical technique used to determine the elemental composition of materials. Handheld XRF analyzers work by measuring the fluorescent (or secondary) X-rays emitted from a sample when excited by a primary X-ray source. Each of the elements present in a sample produces a set of characteristic fluorescent X-rays, or “unique fingerprints”. These “fingerprints” are distinct for each element, making handheld XRF analysis an excellent tool for quantitative and qualitative measurements.

Portable XRF analyzers quantitatively measure the composition of elements in metals and alloys and compare the latter with a library of tabulated values for common standardized alloy grades found in the industries. Those tables include the composition limits for these alloy grades. The standard library includes about 500 alloy grades of all metal bases including 60 common copper alloys using the composition defined by the Copper Development Association. The alloy libraries can be augmented and customized by the user.

Note that there are other libraries, like Chinese and German standards, which may vary slightly. For example, the naval brass grade C46400 is the equivalent of the Chinese HSn62-1 according to GB (Guobiao) Standards and CuZn38Sn1 according to DIN Standards.

How Accurate is XRF for Copper Analysis?

Often, attendees ask about the measurement accuracy that is achievable with XRF analyzers.

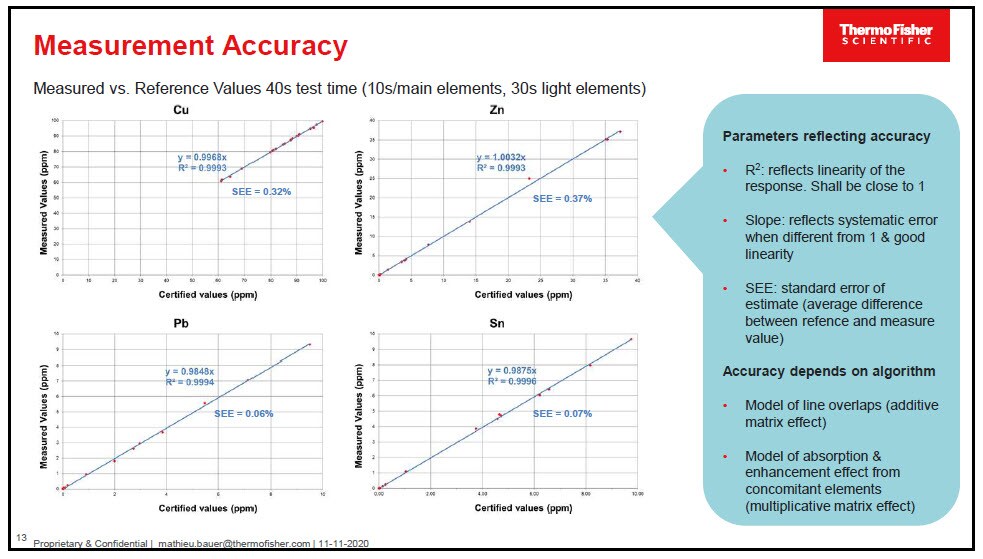

Here is a slide that shows the results obtained for a set of 24 copper alloys reference material with various composition. The testing time was 40seconds, which is a relatively long measurement for this method.

The certified reference values were plotted against measured values for copper and 3 common alloying elements: zinc, lead and tin.

For all four elements, one can see that the correlations between reference and measured values are overall excellent with R2 of at least 0.999. A good correlation indicates that the algorithm accurately corrects for existing matrix effects.

Also, the slope of the regression, being close to 1, demonstrates that systematic error or bias of the analytical response is low.

And finally, the standard error of estimate, which is the average difference between certified and measured values over the investigated range of concentration is also relatively low for the difference elements, ranging from 0.06% for lead to 0.37% for zinc.

Hence overall one can state the analytical performance in terms of accuracy is close to results achieved in a laboratory.

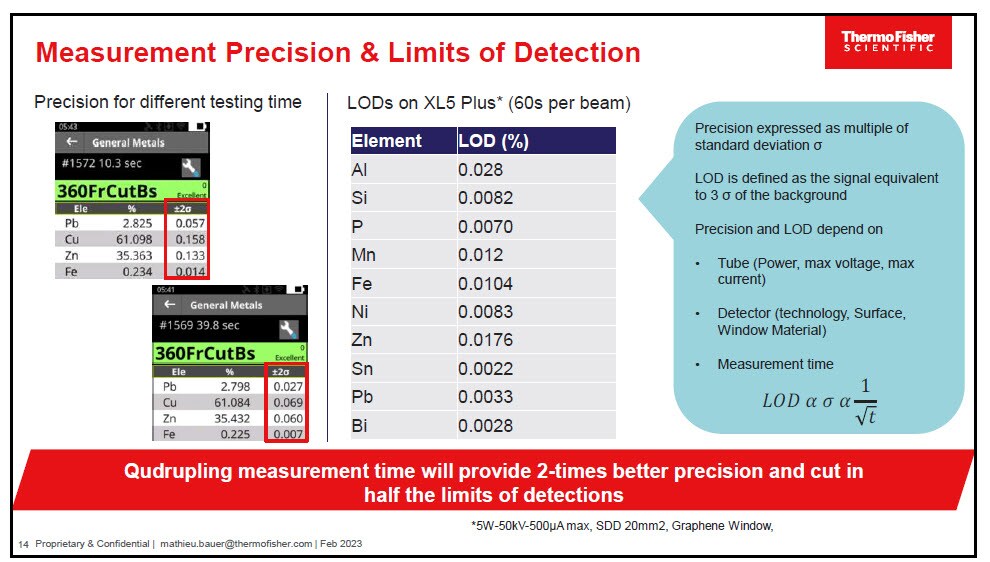

The second figure of merit we reviewed was precision, which is generally expressed as a multiple of the standards deviation. In XRF, the standard deviation of a measurement, follows counting statistics, so it can be calculated from the total number of counts recorded for a given signal. The uncertainty on 2 sigma standard deviation is displayed next to the value of the concentration and decreases at increasing measurement time, as you can see here on the screenshot given here for different measurement times or 10 seconds and 40seconds.

The limit of detection is the smallest amount that can be detected using an analytical method. For most of the elements, the limits of detection are between 0.002% and 0.03%.

Both precision and limits of detection depend essentially on the hardware of the analyzer such as tube power, maximum voltage, and maximum current as well as the technology, the surface, and the window material of the detector. Both measurement precision and the limits of detection will improve proportionally to the inverse of the square root of the measurement time.

In other words, one needs to increase the measurement time by a factor of four to double the precision and cut in half the limits of detection.

One of the main strengths of handheld XRF instruments is being able to measure accurately the composition of copper alloys within few seconds, and identify at the same time the alloy grade. (This is an advantage to scrap metal recyclers as it makes manual sorting of items made of copper and its alloys much easier and quicker.)

To illustrate these capabilities, we analyzed 8 examples of common copper alloys. You can download the presentation to see the results.

Download the full slide presentation

Leave a Reply