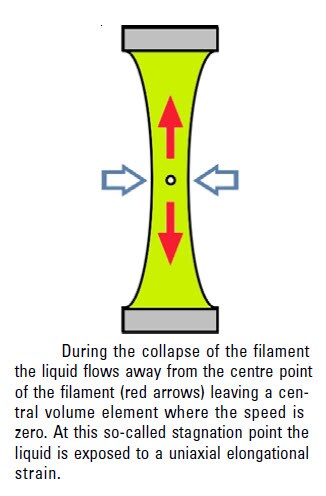

Our last article talked about enhanced oil recovery (EOR) techniques used in oil exploration. We specifically addressed polymer flooding and the increasing demand for analytical techniques capable of characterizing the extensional properties of low viscous polymer solutions. In order to get a systematic characterization of the synthetic porous media made of sand or similar materials, we conducted an experiment using an extensional rheometer for low viscous fluids to test the elongational behavior. Since the elongational viscosity of liquids is not accessible using a rotational viscometer or rheometer, an elongational rheometer is needed.  This technology works by pulling a small volume of a liquid apart to form a liquid filament. It measures the thickness of this filament, or more precisely, how quickly this filament collapses. The thickness of the collapsing filament is measured at the mid-point between the two plates and plotted as a function of time. In this particular test, two different samples were selected from a variety of powder polyacrylamides for polymer flooding. According to the chemical characteristics of the oilfield being tested, A salt solution containing CaCl2 and NaCl was prepared to simulate the real-life chemical conditions in the field. A 5000 ppm polymer solution was prepared from both polymer samples. To prepare each solution, a measured amount of the salt water was filled into a glass container with a screw-on lid. A stirring magnet was added and the polymer was introduced into the vortex of the stirred salt water. The glass was closed with its lid and carefully sealed with a flexible sealing tape to avoid any changes in concentration due to evaporation. After some hours of slow stirring, the polymer solutions were tested with the extensional rheometer. Due to the low viscosity of the samples, 4 mm plates were selected. Using a small syringe without needle the samples were filled into a 2 mm gap between the plates at 20 °C. Within 50 ms the upper plate was lifted to 6.5 mm above the lower plate, which equals a Hencky Strain of 1.2. Under these test conditions the 2 polyacrylamides showed a significant difference in break-up time. The filament formed by Polymer 1 was less stable, collapsing after approximately 0.01 s, whereas the filament of Polymer 2 lasted for 1.1 s. We saw that both collapses happened abruptly. The normalized filament diameter (DN = actual diameter divided by initial diameter) is a function of time. Both polymer solutions started with DN-values around 0.3, which stayed almost constant until the break-up occurred. This behaviour indicated that both polymers had an extended coil structure in this kind of solvent. Based on the raw data, the instrument calculated the apparent extensional viscosity plotted against the elongational strain. Again the behaviour of the two polymers differed significantly. While Polymer 1 showed an almost constant viscosity, Polymer 2 exhibited a strong viscosity increase around a strain of 3. For flooding projects a rather constant viscosity has the advantage of a more uniform behaviour independent of the actual strain, which depends on pore diameter and flow speed. The experiment showed that with a specific extension rheometer, it is possible to test the elongational behaviour of even low viscous liquids like the flooding solutions tested for this report. Since the elongational viscosity of liquids is not accessible using a rotational viscometer or rheometer, an elongational rheometer is the perfect complement to get the full information needed to understand applications, which are clearly influenced or even dominated by elongational flow effects. This is especially true when the real application, like polymer flooding of an oilfield, cannot be accessed directly and any error could cause costly consequences. For test details, including charts, plots, and specific instrument used, read the application note Enhanced Oil Recovery and Elongational Flow.

This technology works by pulling a small volume of a liquid apart to form a liquid filament. It measures the thickness of this filament, or more precisely, how quickly this filament collapses. The thickness of the collapsing filament is measured at the mid-point between the two plates and plotted as a function of time. In this particular test, two different samples were selected from a variety of powder polyacrylamides for polymer flooding. According to the chemical characteristics of the oilfield being tested, A salt solution containing CaCl2 and NaCl was prepared to simulate the real-life chemical conditions in the field. A 5000 ppm polymer solution was prepared from both polymer samples. To prepare each solution, a measured amount of the salt water was filled into a glass container with a screw-on lid. A stirring magnet was added and the polymer was introduced into the vortex of the stirred salt water. The glass was closed with its lid and carefully sealed with a flexible sealing tape to avoid any changes in concentration due to evaporation. After some hours of slow stirring, the polymer solutions were tested with the extensional rheometer. Due to the low viscosity of the samples, 4 mm plates were selected. Using a small syringe without needle the samples were filled into a 2 mm gap between the plates at 20 °C. Within 50 ms the upper plate was lifted to 6.5 mm above the lower plate, which equals a Hencky Strain of 1.2. Under these test conditions the 2 polyacrylamides showed a significant difference in break-up time. The filament formed by Polymer 1 was less stable, collapsing after approximately 0.01 s, whereas the filament of Polymer 2 lasted for 1.1 s. We saw that both collapses happened abruptly. The normalized filament diameter (DN = actual diameter divided by initial diameter) is a function of time. Both polymer solutions started with DN-values around 0.3, which stayed almost constant until the break-up occurred. This behaviour indicated that both polymers had an extended coil structure in this kind of solvent. Based on the raw data, the instrument calculated the apparent extensional viscosity plotted against the elongational strain. Again the behaviour of the two polymers differed significantly. While Polymer 1 showed an almost constant viscosity, Polymer 2 exhibited a strong viscosity increase around a strain of 3. For flooding projects a rather constant viscosity has the advantage of a more uniform behaviour independent of the actual strain, which depends on pore diameter and flow speed. The experiment showed that with a specific extension rheometer, it is possible to test the elongational behaviour of even low viscous liquids like the flooding solutions tested for this report. Since the elongational viscosity of liquids is not accessible using a rotational viscometer or rheometer, an elongational rheometer is the perfect complement to get the full information needed to understand applications, which are clearly influenced or even dominated by elongational flow effects. This is especially true when the real application, like polymer flooding of an oilfield, cannot be accessed directly and any error could cause costly consequences. For test details, including charts, plots, and specific instrument used, read the application note Enhanced Oil Recovery and Elongational Flow.

Leave a Reply