Search

半導体ジオメトリの縮小により、パスファインディング分析の難易度がますます高まっています。複数のワークフローを1つのソリューションに効果的に組み合わせることができるシステムは、研究室にとっては規模の経済性を、製造施設にとっては投資収益率を向上させることができます。また、床面積や予算が限られているため、ラボでは多くの異なる機器を使用するのではなく、複数の分析ツールを1つのシステムに統合することを推進しています。

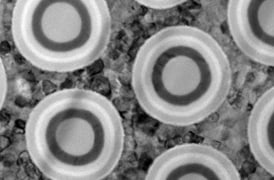

レーザーアブレーションは、走査型電子顕微鏡(SEM)などの二次的な装置でさらに分析を行うために、固体表面から材料の層を除去するために使用されてきました。フェムト秒レーザーは、DualBeam(集束イオンビームとSEMの組み合わせ)などの他の装置と組み合わせることができます。これにより、1つのシステム内で独自のin situワークフローが実現し、個別のツールが不要になり、コストとラボ内の占有スペースを減らすことができます。これらの技術を組み合わせることで、高度なパッケージング分析ラボは、試料の完全性を維持しながら、ナノメートル分解能によってミリメートルスケールの物質を3Dで迅速にキャラクタリゼーションできます。プラズマ集束イオンビーム(PFIB)を使用すれば、通常のガリウムイオンFIBの最大15,000倍の速度で、大容量3Dおよび表面下の正確なデータを取得することも可能です。

サーモフィッシャーサイエンティフィックは、当社のクラス最高レベルのSEMシステムとPFIBおよび試料室内フェムト秒レーザービームを組み合わせたレーザーツールとDualBeamツールを提供しています。これにより、In-situアブレーション機能を使用して高分解能のイメージングおよび分析を実行でき、これまでにない材料除去率と、ナノメートル分解能での高速ミリメートルスケールの特性評価が可能になります。

半導体のパスファインディングと開発

高性能半導体デバイス製造を可能にするソリューションや設計へ導く高度な電子顕微鏡、集束イオンビーム、および関連する分析手法。

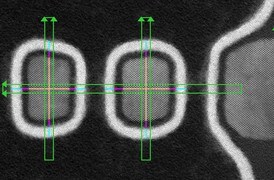

歩留り改善と計測

当社は、幅広い半導体アプリケーションやデバイスの生産性向上と歩留り改善に寄与する、欠陥分析、計測、およびプロセス制御のための高度な分析機能を提供しています。

物理解析および化学分析

継続的な性能要求により、小型で高速、かつ安価な電子デバイス開発が促進されています。これらの製造には、多岐に渡る半導体およびディスプレイデバイスのイメージング、分析、解析を行う、生産性の高い装置とワークフローが重要な役割を果たします。

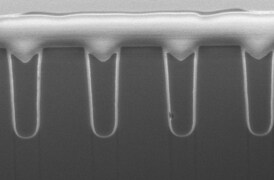

パワー半導体デバイス解析

電力用装置には、障害位置特定にかかわる特有の課題があります。これは主に、動力用装置のアーキテクチャとレイアウトを原因としています。当社のパワー半導体デバイス解析ツールとワークフローを使用すると、動作条件下の不良個所をすばやく特定し、材料、インターフェース、装置構造の高精度かつハイスループットの特性分析を行えます。

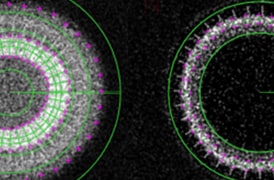

半導体材料およびデバイスの解析

半導体デバイスが微細化し複雑になるにつれて、新しい設計と構造が必要になります。生産性の高い3D解析ワークフローはデバイス開発時間の短縮や、歩留まりの最大化を実現し、デバイスが業界の将来のニーズを確実に満たすようにします。