Search

Materials Science

TEM Sample Preparation Techniques

FIB sample preparation for TEM analysis with DualBeam instruments.

Sample preparation for scanning/transmission electron microscopy (S/TEM) analysis is considered to be one of the most critical but challenging and time-consuming tasks in materials characterization labs. Conventional methods used to prepare ultra-thin samples required for S/TEM are slow, typically requiring many hours or even days of effort by highly trained personnel. This is further complicated by the variety of different materials and the need for site-specific information. For more than 30 years, Thermo Fisher Scientific has been continuously developing and optimizing sample preparation instruments and introducing software that enable in situ TEM sample preparation that allows researchers to accelerate their research and fast-track innovation.

Thermo Fisher Scientific has 30+ years of TEM sample preparation expertise. In 1993, we introduced DualBeam (FIB-SEM, focused ion beam – scanning electron microscopy) technology to give you cutting-edge sample preparation tools that are accessible, robust, and reliable. This begins with a highly stable column and high-quality source, which allows for excellent performance even at low voltages. Final polishing of the lamella using energies as low as 500 V greatly reduces damage, even to beam sensitive materials, and delivers unrivaled sample quality. For gallium-free sample preparation, Thermo Fisher Scientific has a broad portfolio of plasma FIB products, including the Thermo Scientific Helios Hydra DualBeam, which offers fast switching between four ion beam species; xenon, argon, oxygen, and nitrogen.

Additionally, Thermo Scientific SmartAlign Technology eliminates the need for any user alignments of the electron column, which not only minimizes maintenance, but also increases your productivity. Auto-tuning tools, embedded into the user interface, further increasing your ability to get high-quality images, tuning the image up to 10-times faster than standard manual alignment.

Quality hardware is supported by a suite of software solutions that enhance and simplify sample preparation. Thermo Scientific AutoTEM 5 Software enables fully automated in situ lamella preparation and lift-out, allowing even novice users to produce quality samples. This greatly expands the accessibility of the instrument, thereby increasing throughput as sample preparation is no longer reliant on expert operation. Moreover, full automation allows maximum utilization of system time with unattended overnight operation, resulting in greatly enhanced productivity.

TEM sample preparation is part of a multi-scale, multi-modal workflow that includes microCT, (P)FIB-SEM, and (S)TEM. First, data is acquired using the microCT, followed by data reconstruction and analysis using Thermo Scientific Avizo Software. Avizo Software visualizes the data and enables you to precisely locate the suitable regions of interest (ROI) for further exploration of the sample. When the ROI is identified, the workflow progresses through higher-resolution imaging and sample preparation with a plasma-focused ion beam (PFIB) DualBeam to atomic-scale analysis in a transmission electron microscope (TEM). When combined, these technologies provide a complete understanding of sample structure and composition, accelerating development of novel materials.

Automated S/TEM sample preparation in a multiscale workflow

Joseph Michael on how TEM sample preparation has progressed over the past 30 years

Joseph Richard Michael, who worked many years at Sandia National Laboratories in Materials, Physical and Chemical Sciences, tells his story of how TEM sample preparation changed the way he and his fellow materials scientists were able to do their research.

The Single-Beam and Dual-Beam Revolution: How FIB Instruments Transformed TEM Sample Preparation

In this podcast we hear David Foord, product director and materials scientist, in talks with some of his colleagues at Thermo Fisher Scientific. What started as a casual internal conversation around the driving force behind 30+ years of ion beam technology was so interesting that we wanted to share David’s story with you. This podcast proves that people at Thermo Fisher Scientific drive the field of materials science forward with solution-focused innovation that always circles around one question: What problem is this technology going to solve?

Nanoscale Materials Characterization

Understanding the nanoscale characteristics of materials is the first step in creating the next generation of lighter, stronger, and more energy efficient solutions. With our electron microscopy solutions, we help you simplify this complex material journey and accelerate your nanoscale materials research. Nanoscale workflow is a journey of material from bulk to nanometer scales using our DualBeam FIB-SEM for sample preparation and Transmission Electron Microscopes for material analysis.

Introducing Helios 5 DualBeam

Learn how advanced automation capabilities, increased robustness and stability enhancements in the Helios 5 and AutoTEM 5 software can significantly increase sample preparation throughout by allowing unattended and even overnight operation.

Toward “Damage-Free” TEM specimen preparation by Focused Ion Beam without Gallium

Diminish the challenges associated with focused ion beam (FIB) sample preparation for high resolution transmission electron microscopy (HR-TEM). Dr. Chengge Jiao, Staff Scientist of Applications Development at Thermo Fisher Scientific, explains how to tailor processing conditions and select the right FIB ion species for certain groups of materials to achieve optimized results.

Nano-, micro-, and mesoscale sample preparation by focused ion beam and laser milling

Listen to Dr. Joakim Reuteler, a FIB expert from ETH Zurich, discuss how gallium focused ion beam, multi-ion species plasma FIB, and ultra-short-pulse laser milling can help you prepare samples for a wide range of applications.

Introducing Helios 5 DualBeam

Learn how advanced automation capabilities, increased robustness and stability enhancements in the Helios 5 and AutoTEM 5 software can significantly increase sample preparation throughout by allowing unattended and even overnight operation.

Toward “Damage-Free” TEM specimen preparation by Focused Ion Beam without Gallium

Diminish the challenges associated with focused ion beam (FIB) sample preparation for high resolution transmission electron microscopy (HR-TEM). Dr. Chengge Jiao, Staff Scientist of Applications Development at Thermo Fisher Scientific, explains how to tailor processing conditions and select the right FIB ion species for certain groups of materials to achieve optimized results.

Nano-, micro-, and mesoscale sample preparation by focused ion beam and laser milling

Listen to Dr. Joakim Reuteler, a FIB expert from ETH Zurich, discuss how gallium focused ion beam, multi-ion species plasma FIB, and ultra-short-pulse laser milling can help you prepare samples for a wide range of applications.

Prozesskontrolle mittels Elektronenmikroskopie

Die moderne Industrie verlangt einen hohen Durchsatz bei erstklassiger Qualität. Diese Balance wird durch eine robuste Prozesskontrolle aufrechterhalten. REM- und TEM-Geräte mit spezieller Automatisierungssoftware bieten schnelle, mehrskalige Informationen für die Überwachung und Verbesserung von Prozessen.

Qualitätskontrolle und Fehleranalyse

Qualitätskontrolle und Qualitätssicherung sind in der modernen Industrie von entscheidender Bedeutung. Wir bieten eine Reihe von EM- und Spektroskopiegeräten für die mehrskalige und multimodale Analyse von Mängeln, mit denen Sie zuverlässige und fundierte Entscheidungen für die Kontrolle und Verbesserung von Prozessen treffen können.

Grundlagenforschung in der Materialforschung

Neuartige Materialien werden in immer kleineren Dimensionen untersucht, um ihre physikalischen und chemischen Eigenschaften bestmöglich zu kontrollieren. Die Elektronenmikroskopie gibt Forschern wichtige Einblicke in eine Vielzahl von Materialeigenschaften auf der Mikro- bis Nanoebene.

Batterieforschung

Die Entwicklung von Batterien wird durch die Multiskalen-Analyse mit Mikro-CT, REM und TEM, Raman-Spektroskopie, XPS und digitaler 3D-Visualisierung und 3D-Analyse ermöglicht. Erfahren Sie, wie dieser Ansatz die strukturellen und chemischen Informationen liefert, die für den Bau besserer Batterien benötigt werden.

Polymerforschung

Die Mikrostruktur von Polymeren bestimmt die Eigenschaften und die Leistungsfähigkeit des Materials. Die Elektronenmikroskopie ermöglicht eine umfassende Analyse der Morphologie und Zusammensetzung von Polymeren im Mikroskalenbereich für Anwendungen in der F+E und Qualitätskontrolle.

Metallforschung

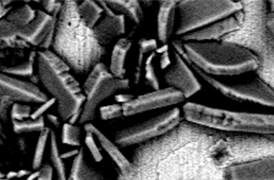

Die effektive Produktion von Metallen erfordert eine präzise Kontrolle von Einschlüssen und Ausscheidungen. Unsere automatisierten Geräte können eine Vielzahl von Aufgaben ausführen, die für die Metallanalyse wichtig sind, einschließlich der Zählung von Nanopartikeln, der chemischen Analyse mittels EDS und der Vorbereitung von TEM-Proben.

Katalyseforschung

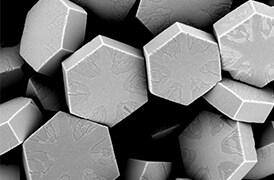

Katalysatoren sind für einen Großteil der modernen industriellen Prozesse von entscheidender Bedeutung. Ihre Effizienz hängt von der mikroskopischen Zusammensetzung und Morphologie der katalytischen Partikel ab; EM mit EDS eignet sich ideal für die Untersuchung dieser Eigenschaften.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.