Search

Talos F200i Transmission Electron Microscope

The Thermo Scientific Talos F200i (S)TEM is a 20-200 kV field emission (scanning) transmission electron microscope uniquely designed for performance and productivity across a wide range of Materials Science samples and applications. Its standard X-Twin pole piece gap—giving the highest flexibility in applications—combined with a reproducibly performing electron column opens opportunities for high-resolution 2D and 3D characterization, in situ dynamic observations, and diffraction applications.

Talos F200i Transmission Electron Microscope advantages

Designed for multi-user and multi-discipline environments, the Talos F200i (S)TEM is also ideal for novice users. It is equipped with the Thermo Scientific Velox user interface, which is immediately familiar since it is shared across all Thermo Scientific TEM platforms. All TEM daily tunings have been automated to provide the best and most reproducible setup. The Align Genie automation software eases the learning curve for novice operators, reduces tensions in a multi-user environment, and improves time-to-data for the experienced operator. A side-entry retractable Energy Dispersive X-ray Spectroscopy (EDS) detector can be added to the configuration to enable chemical analysis.

Compact design

The smaller footprint and dimensions of the Talos F200i facilitate accommodation of this tool in more challenging spaces. In addition, this compact design eases access for service needs while also reducing infrastructure and support costs.

Productivity for all users

To further enhance productivity, especially in multi-user, multi-material environments, the constant-power objective lenses, low-hysteresis design, and remote operation with the SmartCam Camera allow for straightforward reproducible mode and high-tension switches. The Talos F200i (S)TEM also features educational online help. Simply pressing F1 with the mouse hovering over a control panel quickly opens relevant information.

Talos F200i Transmission Electron Microscope features

Large area fast acquisition of Gold-Nickel nanoparticles

Example of large-area, high-resolution EDS mapping with Dual-X on gold-nickel nanoparticles, acquired in less than one minute. Sample courtesy of J. Bursik, Institute of Physics of Materials, Brno.

Revealing details on Silver Nickel core-shell nanoparticles

Example of high-resolution EDS mapping of AgNi nanoparticles which are effectively used as catalysts for reduction of nitro compounds (for example 4-nitrophenol, 4-nitroaniline) and degradation of organic dyes. The individual EDS maps reveal that system Ag0.6Ni0.4 showed the highest catalytic activity for reduction and degradation reaction of nitro compounds and organic dyes. AgNi nanoparticles are also studied as catalysts for generation of hydrogen. In this use case, the hydrogen generation rate of AgNi nanoparticles was found to be much higher compared to Ag and Ni nanoparticles of similar size. Also a single map reveals that one of the shells is actually Sulphur instead of Nickel. Sample courtesy of J. Bursik, Institute of Physics of Materials, Brno.

Beam-sensitive analytics on Co-g-C3N4/Pt

Example of high-resolution EDS mapping of beam-sensitive material used for photocatalytic hydrogen evolution. The small nanoparticles (Pt) act as active sites for the photocatalytic reaction. These nanoparticles are studied to observe the structure of Co-g-C3N4 loaded with Pt nanoparticles and find the relationship between the position of Co atoms and Pt nanoparticles to analyze the reason for improved photocatalytic activity of this sample. In this experiment, it was assumed that Co should be atomically dispersed or located with a diameter of less than 1 nm (single atomic dispersion) on the surface of g-C3N4, and that the Pt nanoparticles should be deposited on the surface of Co-g-C3N4. This was confirmed by the results of elemental mapping data. Sample courtesy of Prof. ShengChun Yang, Xi’an Jiaotong University, China.

Talos F200i for Materials Science

The Thermo Scientific Talos F200i S/TEM is a 20-200 kV field emission (scanning) transmission electron microscope uniquely designed for performance and productivity across a wide range of Materials Science samples and applications. Its standard X-Twin pole piece gap—giving the highest flexibility in applications—combined with a reproducibly performing electron column opens opportunities for high-resolution 2D and 3D characterization, in situ dynamic observations, and diffraction applications.

Large area fast acquisition of Gold-Nickel nanoparticles

Example of large-area, high-resolution EDS mapping with Dual-X on gold-nickel nanoparticles, acquired in less than one minute. Sample courtesy of J. Bursik, Institute of Physics of Materials, Brno.

Revealing details on Silver Nickel core-shell nanoparticles

Example of high-resolution EDS mapping of AgNi nanoparticles which are effectively used as catalysts for reduction of nitro compounds (for example 4-nitrophenol, 4-nitroaniline) and degradation of organic dyes. The individual EDS maps reveal that system Ag0.6Ni0.4 showed the highest catalytic activity for reduction and degradation reaction of nitro compounds and organic dyes. AgNi nanoparticles are also studied as catalysts for generation of hydrogen. In this use case, the hydrogen generation rate of AgNi nanoparticles was found to be much higher compared to Ag and Ni nanoparticles of similar size. Also a single map reveals that one of the shells is actually Sulphur instead of Nickel. Sample courtesy of J. Bursik, Institute of Physics of Materials, Brno.

Beam-sensitive analytics on Co-g-C3N4/Pt

Example of high-resolution EDS mapping of beam-sensitive material used for photocatalytic hydrogen evolution. The small nanoparticles (Pt) act as active sites for the photocatalytic reaction. These nanoparticles are studied to observe the structure of Co-g-C3N4 loaded with Pt nanoparticles and find the relationship between the position of Co atoms and Pt nanoparticles to analyze the reason for improved photocatalytic activity of this sample. In this experiment, it was assumed that Co should be atomically dispersed or located with a diameter of less than 1 nm (single atomic dispersion) on the surface of g-C3N4, and that the Pt nanoparticles should be deposited on the surface of Co-g-C3N4. This was confirmed by the results of elemental mapping data. Sample courtesy of Prof. ShengChun Yang, Xi’an Jiaotong University, China.

Talos F200i for Materials Science

The Thermo Scientific Talos F200i S/TEM is a 20-200 kV field emission (scanning) transmission electron microscope uniquely designed for performance and productivity across a wide range of Materials Science samples and applications. Its standard X-Twin pole piece gap—giving the highest flexibility in applications—combined with a reproducibly performing electron column opens opportunities for high-resolution 2D and 3D characterization, in situ dynamic observations, and diffraction applications.

Available with a wide range of high-resolution field emissions guns (FEG)

Choose S-FEG, high-brightness X-FEG, or ultra-high-brightness Cold Field Emission Gun (X-CFEG). X-CFEG combines the best (S)TEM imaging with the best energy resolution.

Available with Dual EDS technology

Choose the best EDS detector for your needs, ranging from a single 30 mm² detector to dual 100 mm² detectors for high throughput (or low-dose) analytics.

High-quality STEM/TEM images and accurate EDS

Acquire high-quality TEM or STEM images with the innovative and intuitive Velox Software user interface in very a simple way. Unique EDS absorption correction in Velox Software enables the most accurate quantification.

Best all-round in situ capabilities

Add tomography or in situ sample holders. Fast cameras, smart software, and our wide X-TWIN objective lens gap enable 3D imaging and in situdata acquisition with minimal compromise to resolution and analytical capabilities.

Increased productivity

Ultra-stable column and remote operation with the SmartCam Camera and constant-power objective lenses for swift mode and high-voltage (HT) switches. Fast and easy switching for multi-user environments.

Most repeatable data

All daily TEM tunings, such as focus, eucentric height, beam shift, condenser aperture, beam tilt pivot points and rotation center are automated, ensuring you always start from optimum imaging conditions. Experiments can be repeated reproducibly, allowing more focus on research instead of the tool.

Large field-of-view imaging at high speed

The 4k × 4k Ceta CMOS camera with its large field of view enables live digital zooming with high sensitivity and high speed over the entire high-tension range.

Compact design

Smaller footprint and dimensions facilitate accommodating this tool in more challenging spaces while reducing infrastructure and support costs.

| TEM |

|

| Operating system XX units |

|

| Vacuum system |

|

| STEM imaging |

|

| Energy disersive x-ray spectroscopy (EDS) |

|

| Electron energy loss spectroscopy (EELS) |

|

| Gun brightness 200 kV |

|

Partnering in sustainability — ACT label

Understand your lab's environmental impact with the Talos F200i TEM's ACT label. Created by My Green Lab, the ACT label sets the standard for determining the environmental impact of laboratory products and helps labs make informed, sustainable purchasing decisions.

Process control using electron microscopy

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Energy Dispersive Spectroscopy

Energy dispersive spectroscopy (EDS) collects detailed elemental information along with electron microscopy images, providing critical compositional context for EM observations. With EDS, chemical composition can be determined from quick, holistic surface scans down to individual atoms.

_Technique_800x375_144DPI.jpg)

3D EDS Tomography

Modern materials research is increasingly reliant on nanoscale analysis in three dimensions. 3D characterization, including compositional data for full chemical and structural context, is possible with 3D EM and energy dispersive X-ray spectroscopy.

Atomic-Scale Elemental Mapping with EDS

Atomic-resolution EDS provides unparalleled chemical context for materials analysis by differentiating the elemental identity of individual atoms. When combined with high-resolution TEM, it is possible to observe the precise organization of atoms in a sample.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

Electron Energy Loss Spectroscopy

Materials science research benefits from high-resolution EELS for a wide range of analytical applications. This includes high-throughput, high signal-to-noise-ratio elemental mapping, as well as probing of oxidation states and surface phonons.

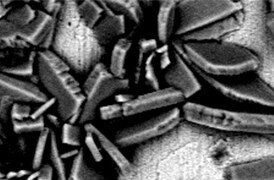

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

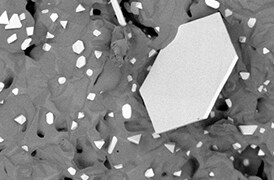

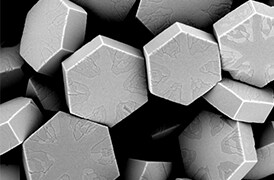

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

Multi-scale analysis

Novel materials must be analyzed at ever higher resolution while retaining the larger context of the sample. Multi-scale analysis allows for the correlation of various imaging tools and modalities such as X-ray microCT, DualBeam, Laser PFIB, SEM and TEM.

The Automated NanoParticle Workflow (APW) is a transmission electron microscope workflow for nanoparticle analysis, offering large area, high resolution imaging and data acquisition at the nanoscale, with on-the-fly processing.

Energy Dispersive Spectroscopy

Energy dispersive spectroscopy (EDS) collects detailed elemental information along with electron microscopy images, providing critical compositional context for EM observations. With EDS, chemical composition can be determined from quick, holistic surface scans down to individual atoms.

_Technique_800x375_144DPI.jpg)

3D EDS Tomography

Modern materials research is increasingly reliant on nanoscale analysis in three dimensions. 3D characterization, including compositional data for full chemical and structural context, is possible with 3D EM and energy dispersive X-ray spectroscopy.

Atomic-Scale Elemental Mapping with EDS

Atomic-resolution EDS provides unparalleled chemical context for materials analysis by differentiating the elemental identity of individual atoms. When combined with high-resolution TEM, it is possible to observe the precise organization of atoms in a sample.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

Electron Energy Loss Spectroscopy

Materials science research benefits from high-resolution EELS for a wide range of analytical applications. This includes high-throughput, high signal-to-noise-ratio elemental mapping, as well as probing of oxidation states and surface phonons.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

Multi-scale analysis

Novel materials must be analyzed at ever higher resolution while retaining the larger context of the sample. Multi-scale analysis allows for the correlation of various imaging tools and modalities such as X-ray microCT, DualBeam, Laser PFIB, SEM and TEM.

The Automated NanoParticle Workflow (APW) is a transmission electron microscope workflow for nanoparticle analysis, offering large area, high resolution imaging and data acquisition at the nanoscale, with on-the-fly processing.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.