Search

Materials Science

Multi Scale Microscopy

Multi-scale analysis and correlative microscopy for observation of samples at various length-scales and imaging modalities.

in the multi-scale analysis workflow.

As materials continue to advance, it is becoming increasingly important to not only examine them at ever-higher resolutions but to obtain these observations within the relevant macroscopic context. This necessitates correlating different imaging modes to the same coordinates for truly contextual insight. Measurements must also be obtained quickly enough for practical application in real-world process control and failure analysis environments. Thermo Fisher Scientific offers a complete workflow for the observation of materials, combining correlated imaging at various scales with additional information such as chemical composition.

Multi-scale analysis begins with micro-scale observation with non-destructive spectroscopic techniques. X-ray microtomography (microCT) produces a complete, 3D rendering of the sample through serial X-ray scans. These scans, or 2D tomograms, are digitally combined to form the 3D structure. With Thermo Scientific Heliscan MicroCT, the series of circular scans is replaced by a single, continuous helical scan. This allows for faster scanning at a lower dose, increasing the accuracy and amount of information obtained. MicroCT observations can provide resolution as low as 400 nm, making it an ideal tool for non-destructive surveying of the sample prior to higher resolution characterization.

Once a region of interest is identified, DualBeam (focused ion beam and scanning electron microscopy, FIB-SEM) instrumentation is used for closer surface analysis and sample extraction. (Note that the focused ion beam can consist of a liquid metal ion source (gallium) or a plasma FIB.) The SEM enables nanoscale surface analysis while the FIB/PFIB is used for serial sectioning, or to extract a thin sample lamella for further observation with transmission electron microscopy (TEM). The addition of a femtosecond laser to the PFIB-SEM allows for even more rapid sample preparation, cross-sectioning or serial sectioning. Subsequent TEM analysis provides atomic-scale materials characterization for complete insight into a sample’s elemental and structural composition.

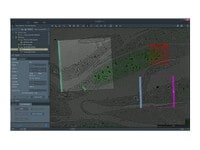

True multi-scale microscopy generates high quality and reliable imaging across all instruments while also accurately aligning them into a complete representation of the sample. With Thermo Scientific automation and data analysis software, the entire multi-scale workflow becomes a guided and routine procedure that can be readily integrated into your process or quality control environment.

*Maps is not directly integrated with mCT, it can load processed CT data.

**AutoScript is not available yet on HeliScan and TEM microscopes.

HeliScan MicroCT analysis used in the correlative study of defects in an oil filter casing made of a glass-fiber-reinforced composite.

Characterizing material failure of an additively manufactured Inconel 718 part with multi-scale analysis. Performed in collaboration with the University of Manchester.

HeliScan MicroCT analysis used in the correlative study of defects in an oil filter casing made of a glass-fiber-reinforced composite.

Characterizing material failure of an additively manufactured Inconel 718 part with multi-scale analysis. Performed in collaboration with the University of Manchester.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Battery Research

Battery development is enabled by multi-scale analysis with microCT, SEM and TEM, Raman spectroscopy, XPS, and digital 3D visualization and analysis. Learn how this approach provides the structural and chemical information needed to build better batteries.

Polymers Research

Polymer microstructure dictates the material’s bulk characteristics and performance. Electron microscopy enables comprehensive microscale analysis of polymer morphology and composition for R&D and quality control applications.

Metals Research and Characterization

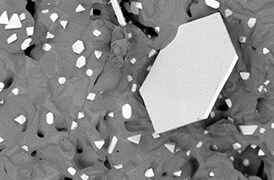

Effective production of metals requires precise control of inclusions and precipitates. Our automated tools can perform a variety of tasks critical for metal analysis including; nanoparticle counting, EDS chemical analysis and TEM sample preparation.

Catalysis Research

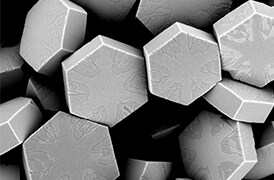

Catalysts are critical for a majority of modern industrial processes. Their efficiency depends on the microscopic composition and morphology of the catalytic particles; EM with EDS is ideally suited for studying these properties.

Oil and Gas

As the demand for oil and gas continues, there is an ongoing need for efficient and effective extraction of hydrocarbons. Thermo Fisher Scientific offers a range of microscopy and spectroscopy solutions for a variety of petroleum science applications.

Geological Research

Geoscience relies on consistent and accurate multi-scale observation of features within rock samples. SEM-EDS, combined with automation software, enables direct, large-scale analysis of texture and mineral composition for petrology and mineralogy research.

Fibers and Filters

The diameter, morphology and density of synthetic fibers are key parameters that determine the lifetime and functionality of a filter. Scanning electron microscopy (SEM) is the ideal technique for quickly and easily investigating these features.

Automotive Materials Testing

Every component in a modern vehicle is designed for safety, efficiency, and performance. Detailed characterization of automotive materials with electron microscopy and spectroscopy informs critical process decisions, product improvements, and new materials.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.