Search

반도체 구조의 지속적인 소형화는, 안정적이고 일관되게 새로운 소자를 생산하고 원하는 사양을 얻음으로써 출시에 걸리는 시간을 단축하기 위해서는 매우 정밀한 회로 편집 및 나노프로토타이핑 도구가 필요하다는 것을 의미합니다. 새로운 기술에 대한 기회를 놓치거나 뒤처질 경우의 잠재적 비용이 매우 높기 때문에 이것은 매우 중요합니다.

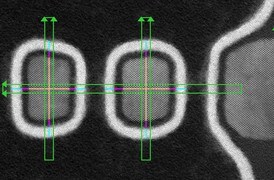

올바른 도구를 사용하면 회로 편집 및 나노프로토타이핑 워크플로우 및 기술을 통해 설계의 성공을 보장하고 재회전 횟수를 줄여(따라서 비용 및 시간 절약) 궁극적으로 출시 시간을 안정적으로 확보할 수 있습니다. 예를 들어, 정밀 집속 이온 빔(FIB) 편집 도구를 사용하면 새로운 회로 설계의 미세 수술(microsurgery) 및 나노프로토타이핑을 수행할 수 있으므로 설계의 재회전을 기다리지 않고 첫 번째 실리콘에서 설계 변경 사항을 확인할 수 있습니다.

Thermo Scientific Centrios 회로 편집 시스템을 사용하면 14nm 및 이를 뛰어 넘는 회로 편집과 신속한 프로토타이핑을 수행하여 시간을 절약하고 설계 성공을 보장할 수 있습니다. 이 도구는 현대적이고 빠른 소비자 중심의 모바일 기술 환경에 맞게 특별히 설계되었으며, 새로운 디자인의 신속한 프로토타이핑은 물론 테스트 및 평가가 가능합니다. 아래 Centrios 제품 페이지에서 더 자세히 알아보기

반도체 경로탐색(Pathfinding) 및 개발

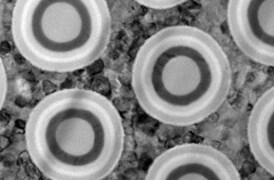

고성능 반도체 장치의 제조에 필요한 실행 가능한 솔루션과 설계 방법을 확인하기 위한 고급 전자 현미경 검사, 집속 이온빔 및 관련 분석 기법.

수율 경사 및 계측

당사에서는 다양한 반도체 응용 분야와 장치의 생산성을 높이고 수율을 높일 수 있도록 설계된 결함 분석, 계측 및 공정 관리를 위한 고급 분석 기능을 제공합니다.

전력 반도체 장치 분석

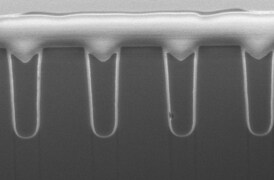

전력 장치는 주로 전력 장치 아키텍쳐 및 레이아웃의 결과로서 오류를 국지화를 위한 고유한 과제를 제기합니다. 저희의 전력 장치 분석 도구와 워크플로우는 작동 조건에서 오류 위치를 빠르게 찾고 물질 특성 분석, 인터페이스, 장치 구조에 대한 정밀하고 고처리량의 분석을 제공합니다.

반도체 물질 및 장치 특성 분석

반도체 장치가 축소되고 복잡해짐에 따라 새로운 설계와 구조를 필요로 하게 되었습니다. 고생산성의 3D 분석 워크플로우는 장치 개발 시간을 단축하고 수율을 극대화할 수 있으며, 장치가 산업의 향후 요구 사항에 부합되도록 보장합니다.