Editor’s Note: This is the second of a five-part webinar series on general extruders and mixers for characterizing and formulating your polymer materials using rheology, viscometry, mixing and extrusion technologies. Watch for a webinar every Tuesday in March.

Typical twin-screw extruders are well-established in the industry for mixing, compounding and processing of viscous materials. They are used in a great variety of polymer applications. The flexibility of twin-screw extrusion equipment allows customers to design a process that can test different polymer formulation and optimize the formulation with the desired characteristics for the final product.

Single-screw laboratory extruders deliver reliable data captured during the extrusion process to verify process parameters (speed, energy, temperature) for unknown materials or to manufacture smaller quantities of a new polymer (as strands, sheets, pellets, blown films) during research and development.

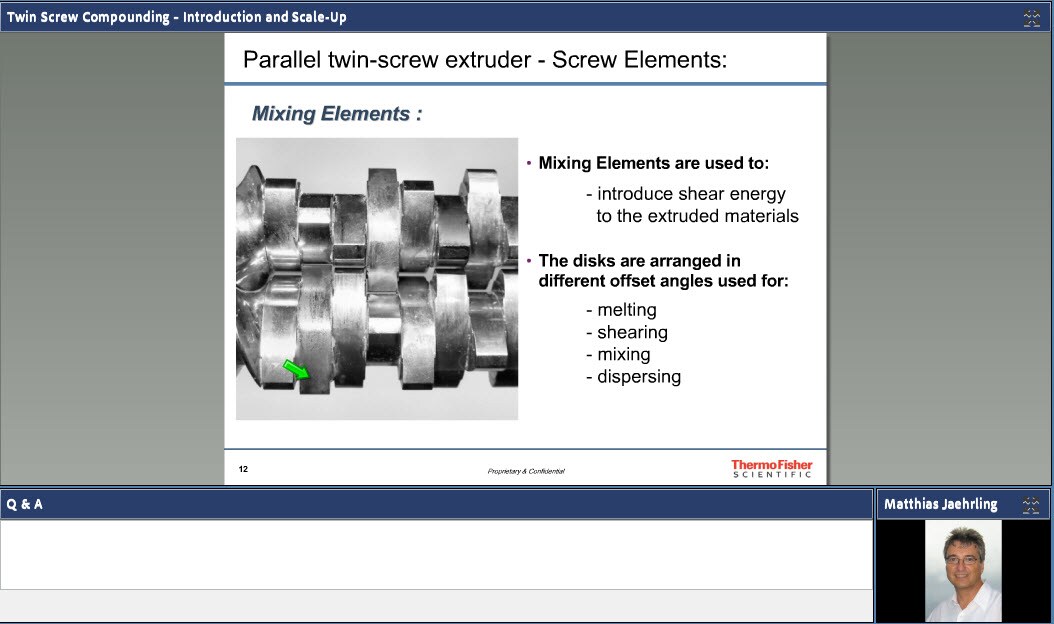

Twin-screw extruders can have a conical or parallel design. The two screws can be counter-rotating or co-rotating, intermeshing or nonintermeshing. Also, the configurations of the screws themselves can be varied using different conveying and mixing elements. Counter-rotating twin-screw extruders are used mainly for processing PVC products, such as pipe, profile, sheet, pellets and film. The co-rotating units are used for compounding materials where thorough mixing is important. Co-rotating twin-screw extruders usually have modular configurations, which makes the equipment quite flexible for adapting to changing applications and material properties.

New functional polymers are continuously taking over new applications in all areas. The compounding process is a decisive factor in development to ensure that the properties of the active ingredients meet the requirements.

We’ve recorded a webinar that explains the principles of compounding based on selected examples from the industry. A further focal point is the scale transfer from research and development to the production process (scale-up). In this 50-minute webinar – geared toward scientists, engineers and experienced staff members from the polymer industry, involved with development and testing of new types of polymer compounds as well as their processing – we’ll cover the basics on extrusion and twin-screw processing, solutions for lab-scale twin-screw compounding, feed and post-extrusion equipment, and how to transfer results from the lab into a larger scale.

Click here to watch the webinar: Twin-Screw Compounding – Introduction and Scale-Up

Here are links to the full series:

- Extrusion Rheology – Usage of the Torque Rheometer

- Twin Screw Compounding – Introduction and Scale-Up

- Downstream Options for Extrusion

- Mixer Test – A Versatile Tool for Polymer Processing

- MIM/PIM Application – Mixer, Compounding, Rheology

Hello is it possible if you share the presentation file to us.

This is a very good article. Thank you for sharing. I look forward to publishing more such works. There are not many such articles in this field.