Do you use portable x-ray fluorescence (XRF) analyzers for elemental analysis so you can identify metals and alloys? Do you wonder if they emit radiation and if they are safe? Do you need to take precautions?

X-ray fluorescence (XRF) is a non-destructive analytical technique used to determine the chemical composition of materials. It is used extensively in the metal manufacturing, inspection and recycling industry. You might use it to identify the metal and alloys in a scrapyard, verify the content of your raw materials in your manufacturing plant, or check the identify of the metal and alloys in a piece of jewelry.

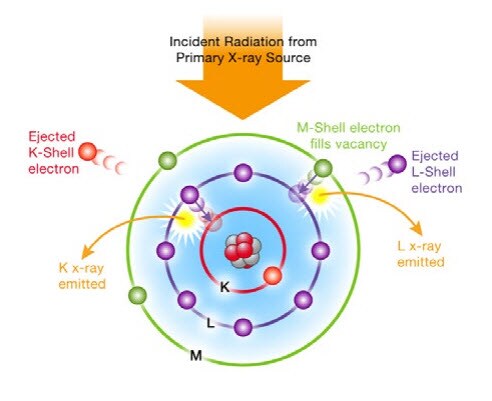

XRF occurs when a fluorescent (or secondary) x-ray is emitted from a sample that is being excited by a primary x-ray source. See image below:

Because this fluorescence is unique to the elemental composition of the sample, XRF is an excellent technology for qualitative and quantitative analysis of the material composition.

Step-by-Step XRF Analysis

- X-rays are produced by the analyzer and pointed at a sample surface.

- The energy causes inner-shell electrons to be ejected.

- Outer-shell electrons fill the vacancies left by the ejected electrons and fluorescent x-rays are emitted.

- The fluorescent x-rays enter the detector and send electronic pulses to the preamp.

- The preamp amplifies the signals and sends them to the Digital Signal Processor (DSP).

- The DSP collects and digitizes the x-ray events and sends the spectral data to the main CPU for processing.

- The CPU analyzes the spectral data to produce detailed composition analysis.

- Composition data and other grade or value identification are displayed and stored in memory for later recall or download to an external PC.

Radiation Safety

During the analysis, the analyzer emits a directed radiation beam when the tube is energized (tube based instrument) or when the shutter is open (isotope based instrument). Reasonable effort should be made to maintain exposures to radiation as far below dose limits as is practical. This is known as the ALARA (As Low as Reasonably Achievable) principle. For any given source of radiation, three factors will help minimize your radiation exposure: time, distance, and shielding.

While the radiation emitted from a portable XRF analyzer is similar to the exposure received in a normal medical or dental x-ray, care must be taken to always point a handheld XRF analyzer directly at the sample and never at a person or a body part.

Radioactive material is considered a hazardous material (HAZMAT) for the purposes of transport. This means that the transportation of a portable XRF device containing radioactive sources is regulated.

Here’s a list of precautions that we have provided to our customers during Radiation Safety Training.

7 Safety Tips When Using Handheld XRF analyzers

- Provide radiation safety training to operators

- Never aim the device at yourself or others when the primary beam (X-ray on) lights are illuminated

- Never hold samples during analysis

- Be aware of primary beam indicator lights

- Handle and use with respect

- Store securely – obey local storage requirements

- If you have a Safety Emergency, notify your Radiation Safety Officer (RSO) and analyzer vendor

This is just a summary of general safety tips; always check your user manual for additional details. (Thermo Fisher Scientific offers free safety training for customers and prospective customers. We recommend that operators of handheld XRF analyzers receive radiation safety training prior to using the analyzer. Safety training may be required by state regulatory authorities as a condition of licensing/registration. Safety training courses can be completed online or at one of our scheduled instructor-led training sessions. The scheduled instructor-led trainings also include an operational training session.)

Want to know more about XRF and how it works… but you don’t want to delve into the details because you are not a scientist? Then download this free eBook – XRF in the Field: XRF Technology for the Non-Scientist, which is written by an expert in X-ray fluorescence (XRF) techniques, and explains the technology in an easy-to-understand manner.

Additional Resources

- Visit our Handheld XRF Technology Learning Center

- Download our free ebooks:

Editor’s Note: This article was originally published July 12, 2016, but has been been updated by fixing broken links and adding the Step-by-Step notes and Safety Tips (from a previous article).

Hi, are the MA. Time, Voltage the same as use for medical test? If we expose a steel alloy with at least half In.Thicknes, all factors are such as exposing a tooth? So its unbelievable for me! Please let me know more infomation, thanks.

Hi Jafar. Thank you for your question. We believe many people may have the same concerns so we are going to publish your question and answer in this week’s 8/11/16 post. Make sure you read Thursday’s article or subscribe so you will know when it is published. Thank you for commenting, and feel free to offer more questions/comments/topics of interest.

Okay sir

cool

Thanks for the info about XRF analyzers. My friend is interested in XRF analyzers. I’ll share this info about XRF analyzers with my friend.