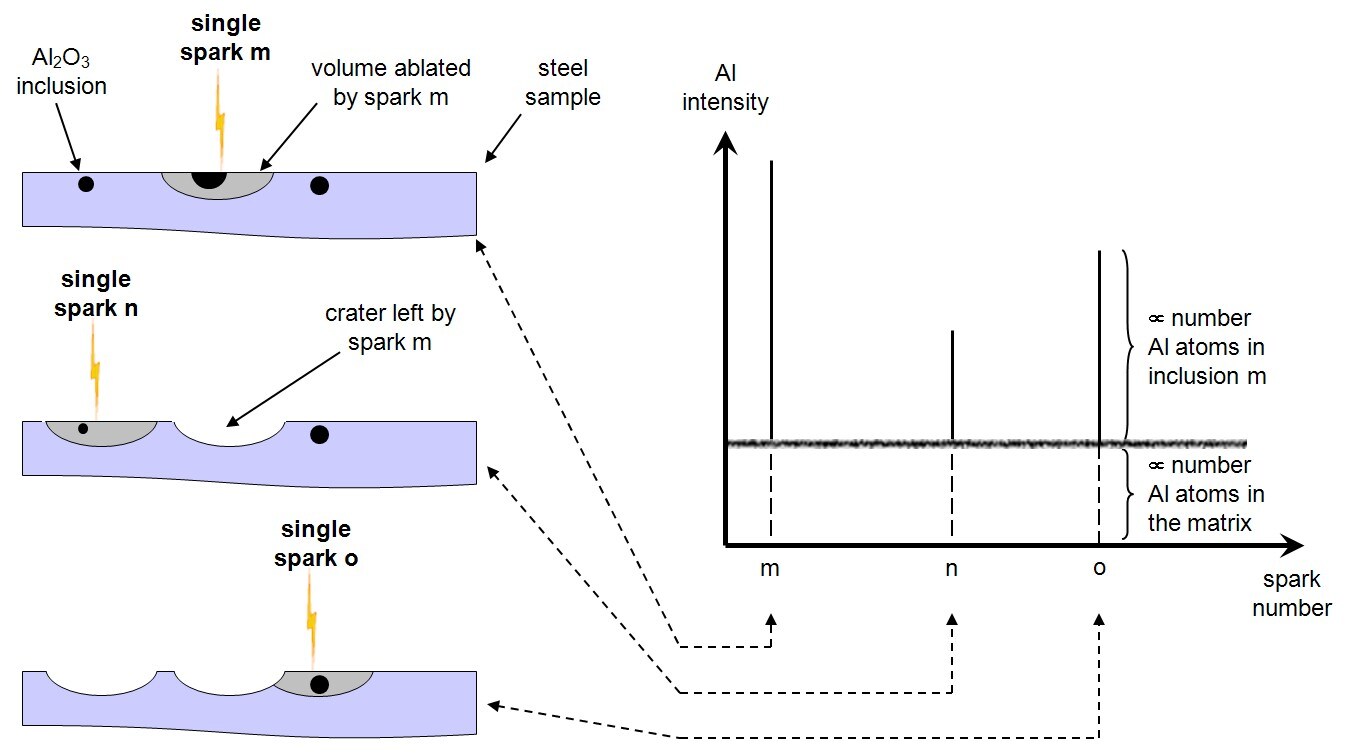

Principle of Spark-DAT illustrated for a steel sample containing Al2O3 inclusions of different sizes.

Non-metallic inclusions are of considerable importance for the steel industry due to the dramatic influence that even small amounts of them may have on properties of the metal (mechanical and others) or on the production process itself. Inclusions can have positive effects and may increase the value of the steel, but most often inclusions signify quality problems and costs. This is true in particular for an increasing number of steel types used for demanding applications and industries (e.g. automotive, aerospace, nuclear, offshore and pipeline industries). Therefore for many companies, a main objective is to keep critical inclusions under very tight control during production.

The modern reference for inclusion analysis is the SEM/EDX (scanning electron microscope coupled with energy dispersive X-ray fluorescence spectroscopy). It takes typically several hours, including sample preparation and interpretation, by far too long to be applicable for production control.

Within the last few years we’ve seen the development of extremely fast and economical OES (Optical Emission Spectrometry) methods which are able to provide inclusion information even during the steel production process. The method uses the principle of Single Spark Acquisition (SSA), where signals from the individual “single sparks” are not summed as in conventional OES acquisition, but processed with special algorithms. Several aspects of this method explain the continuously growing interest from the steel community:

- Inclusion information is available during the production of steel. The inclusion analysis, which is performed in combination with the classical spectrochemical analysis, does not extend the time needed for the traditional OES analysis.

- Drastic reduction of investment costs. The inclusion analysis is performed with the same instrumentation used for production process control.

- Extremely short time for inclusion analysis. A two-run combined analysis takes about 1 minute; it is possible to analyze more than 30 samples per hour.

- No additional cost or time for operations. Sample preparation, maintenance, and service operations are the same as for a standard OES instrument.

The high speed of SSA analysis methods makes them unique for the control of inclusions during the production. They also can be extremely beneficial and simple to implement in other contexts: fast investigative screening, qualification of incoming metallic goods and inclusion control in finished or semi-finished goods. The most advanced methods to date allow:

- The quantitative size (distribution) analysis for various types of inclusions

- The quantitative determination of oxygen down to a few ppm in killed-steels.

Learn more about these unique methods for fast inclusion characterization.

Leave a Reply