Mining companies move a lot of earth, rocks, and minerals. In fact, mines, crushing plants, cement mills, coal preparation plants, sand and gravel operations, coal-fired power plants, and ore beneficiation plants handle a lot of heavy material in bulk that must be weighed, monitored, and fed to crushers, mills and screens to be processed.

Mining companies move a lot of earth, rocks, and minerals. In fact, mines, crushing plants, cement mills, coal preparation plants, sand and gravel operations, coal-fired power plants, and ore beneficiation plants handle a lot of heavy material in bulk that must be weighed, monitored, and fed to crushers, mills and screens to be processed.

Belt conveyer scales are an important part of a mining operation’s bulk material handling system. A belt scale system allows you to monitor production output and inventory, or regulate product loadout, while providing vital information for the effective management and efficient operation of your business.

A belt scale system consists of three major elements: the weighing carriage with load cell(s) measures the weight of material on the belt, the belt speed sensor and electronic integrator joins the output signals from the scale load cell(s) and speed sensor to arrive at a rate of material flow and the total material passed over the scale.

The weighing assembly consists of either one or two modules, depending on conveyor width. The modules support the weigh idler and measure the weight of material on the belt. The speed sensor is mechanically connected to the conveyor’s tail pulley and generates a stream of pulses. Each pulse represents a unit of belt travel. The frequency of the pulse stream is proportional to belt speed. The electronics integrate the output signals from the scale module(s) and speed sensor to arrive at a rate of material flow and the total material passed over the scale.

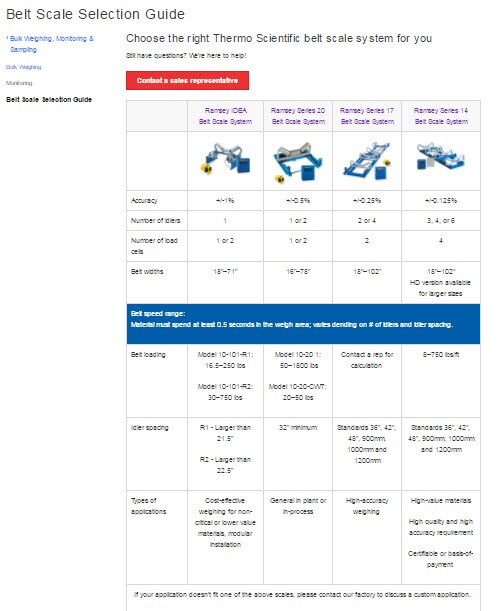

Some belt scale systems provide basic rate information and totalization functions in processes involving non-critical or lower value materials with an accuracy of ±1%. Other belt scale systems can monitor the feed processes with an accuracy of ±0.5%, or with better-than-normal accuracy of ±0.25%. If you must achieve high accuracy in your weighing applications requiring certification by government and regulatory agencies, there are belt scale systems that consist of a 4-idler, 4-load cell weighbridge, speed sensor and electronics to provide stable high-accuracy weighing. These systems provide extremely accurate measurements to within +/-0.125%. If you need that kind of accuracy, it is best to look for electronic belt scales that have received Certificate of Conformance in the United States as issued under the National Type Evaluation Program (NTEP) of the National Conference on Weights and Measures. The National Conference on Weights and Measures issues an NTEP Certificate of Conformance following successful completion of an evaluation of a device. It indicates that the device(s) described in the Certificate is/are capable of meeting applicable requirements.

Most belt conveyor scales are capable of providing reliable results within ±½% of their full-scale rating. Belt conveyor scales that have been certified via the NTEP are capable of providing results that meet the criteria of the National Institute of Standards and Technology (NIST) Handbook-44, which is defined as being within ¼% of actual material load and repeatable within a ¼% bandwidth.

If that doesn’t have you confused enough, there are other options to consider when considering belt scale systems: idlers, idler spacing, load cells, belt widths, belt loading amounts, and even considerations for the type of application. Some systems are better for high-value materials while others are more cost-effective for non-critical or lower value materials.

To help you decide which belt scale system is best for your mining operation, we’ve outlined the options in an easy-to-read belt scale system selection guide so you can decide which belt scale system is right for you. Click on the image, take a look at the chart, and see if it helps you decide.

To help you decide which belt scale system is best for your mining operation, we’ve outlined the options in an easy-to-read belt scale system selection guide so you can decide which belt scale system is right for you. Click on the image, take a look at the chart, and see if it helps you decide.

Leave a Reply